4 minute read • published in partnership with CREAT3D

Insight: How additive manufacturing is supporting positive change in manufacturing

The most forward-thinking business in manufacturing and engineering in the UK have been hugely and rapidly benefiting from integrating 3D printers in house, at low rates of investment. CREAT3D shares how its clients have been realising successes in three key areas: reducing production costs, improving supply chains and generating new revenue streams.

Quick wins to reduce production costs

Using AM isn’t always about prototyping or end-use components. Within every business, there is the opportunity for quick wins in reducing productions costs, by 3D printing production aids, tooling, jigs and fixtures. These are often overlooked applications, but when you take into account the total number, often bespoke and low volume, then they quickly add up.

One of our clients, a large aerospace company, invested £25,000 into new AM equipment, and received return on their investment almost instantly, saving £15,000 with the very first application. Another client, an automotive manufacturer, invested £30,000 and received payback by printing just 6 bespoke jigs, which were previously outsourced.

These applications are quick wins. They will not only reduce production costs, but by using 3D printing, it also lowers materials costs, allows for on-demand (or late production), less reliance on expensive labour and it often results in better performing bespoke designs being produced.

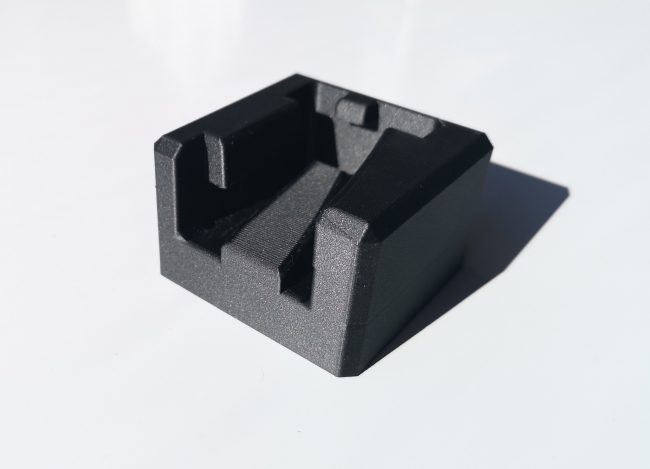

Within every business, there is the opportunity for quick wins in reducing productions costs, by 3D printing production aids, tooling, jigs and fixtures / Picture: CREAT3D

Expert Tooling & Automation saved 96% on this assembly jig, reducing the original CNC machining cost of £300, to a 3D printed cost of just £10.07. The jig was previously made from 4 component parts, now 3D printed in one part.

Return on investment

Traditional fabrication – cost of £300 per part, using CNC machining

3D printing – cost of £10.07 per part

Cost saving – 96% cost saving

Time saving – lead time reduction from 3 weeks to 10 hours (98%)

Improved supply chain management & efficiencies

Many manufacturing firms have outsourced production to Eastern Europe or Asia. Whilst unit costs may have been competitive, often overlooked are the hidden costs of offshoring, typically costs incurred through increased supplier management, logistics, importing, longer lead times and lack of control over production schedules. The inability to fix issues quickly, or the lack of control over delays, especially with unexpected influences such as Covid-19, has highlighted this within global supply chains.

Onshoring some aspects of your production or assembly, by integrating AM in-house, creates a huge positive impact. The savings are seen through supply chain efficiency and improvements, and reduced stock holding and inventory. Costs and lead times are dramatically reduced. Production slots are controlled. Supplier management and purchasing admin is reduced. Responsiveness to customer needs is faster. Innovation is higher.

Mecmesin, an industrial equipment manufacturer, used their in-house AM equipment to produce stock parts, removing the reliance on a third party supplier, reducing their lead time by 98.5% from 5 weeks to 12 hours. As a bonus, they also saw a cost saving of 96%, from £2.98 to £0.11 per unit.

Return on investment – for a batch of 78 parts

Traditional fabrication – unit cost of £2.98

3D printing – unit cost of £0.11

Cost saving – 96% cost saving

Time saving – lead time reduction from 5 weeks to 12 hours (98.5%)

New Revenue Streams

Using AM in-house for design development, R&D, form, fit and function testing allows for faster time to market whilst protecting IP. Furthermore, the range and functions of AM equipment has progressed rapidly, with machines now capable of producing end-use parts, components and products.

Additive manufacturing equipment has progressed rapidly, with machines now capable of producing end-use parts, components and products / Picture: Integrated Design Limited/CREAT3D

This combination of capability creates agility within the business to offer new revenue streams and improved customer satisfaction, through

• Fast “re-tooling” for new production lines

• Quick repairs & maintenance, even acting as temporary fixes whilst OEM parts are sourced

• Fast R&D with control over iterations

• New product development with shortened design feedback loops

• Production of bespoke or highly customised products for the same unit cost

• Production of end components & parts that were previously not feasible due to low production volumes

Fastlane, part of Integrated Design Limited, a security entrance systems manufacturer, used their in-house 3D printer to produce a bespoke end-use housing to incorporate their client’s biometric recognition product. Due to the low volumes and unique requirement, this solution would not have been viable prior to 3D printing. By manufacturing additively, Fastlane was able to deliver a bespoke final product to the client, at low production costs and short lead time. The competitive advantage gained using AM secured Fastlane this new business over their competitors.

Return on investment

Traditional fabrication – cost & time prohibitive

3D printing – bespoke house (end component)

3D printed benefits – production with short lead time (>12 hours) & low production costs (>£10 per unit)

You can read more detailed case studies from peers in your industry, from automotive to industrial machinery and tooling, automation, product design through to EV and aerospace here.