2 minute read - 12th February 2025

Green light for new Sheffield Forgemasters facility

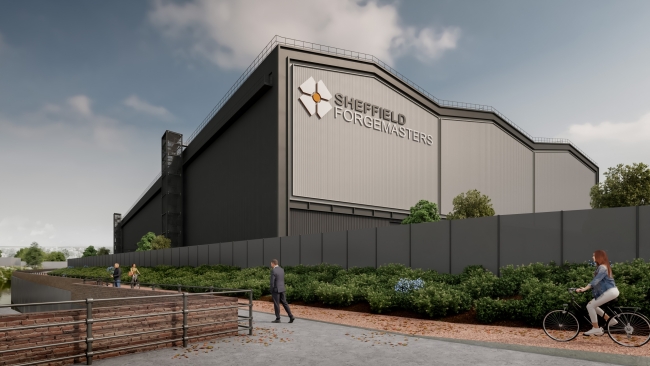

Castings and forgings manufacturer Sheffield Forgemasters has been granted planning permission to build a landmark 30,000 m² machining facility on brownfield land in Sheffield’s Meadowhall district.

Located on a 16-acre plot at Weedon Street, the new facility will be one of the world’s most advanced large machining facilities. It will support the firm’s production for UK defence programmes, and work to prepare the site is already underway. The building will cover a space equal to 12 Olympic-sized swimming pools and will contain some of the largest and most advanced five-axis vertical turning lathes ever produced.

Plans for the new machining facility detail a main building with a footprint of approximately 272.5 x 110 metres and a 32-metre-tall tower. Adjoining the main construction is a second proposed 3,500 m² building, with a state-of-the-art test-house facility and a dedicated training area to transfer vital skills to the next generation of engineers.

Sheffield Forgemasters has secured planning permission to build a new 30,000 m2 machining facility which is set to be operational by the end of 2028 / Picture: Sheffield Forgemasters

Never miss the latest manufacturing news by signing up to our newsletter here

Craig Fisher, programmes director at Sheffield Forgemasters, said: “This planning agreement will see construction of the largest machining hall of its kind in the UK and regeneration of a prominent brownfield site in the city’s industrial centre. It signals an amazing investment for the city and for the wider UK, which will create highly-skilled engineering jobs for decades to come, fully supporting our national defence programmes. The sheer scale of the building will make it an iconic landmark, and will eclipse the construction of the UK’s largest open-die forging line, which is also underway on our adjacent Brightside Lane site.

“What we are creating in the centre of Britain’s historical industrial heartland is unparalleled in the UK and will not only de-risk supply for the UK’s AUKUS defence programme, but it will also deliver technologically advanced and rewarding working facilities for our employees.”

The machining facility will be operational by the end of 2028 and will deliver new levels of speed, accuracy, and efficiency for the manufacture of large, highly complex, nuclear-grade components. Machine tools specialist WaldrichSiegen is building a series of large vertical turning lathes and associated machines for the machining hall, which will be installed and maintained by McDowell Machine Tools.

The facility will contain 17 new machines, including some of the largest and most advanced five-axis vertical turning lathes ever produced / Picture: Sheffield Forgemasters