2 minute read - 11th June 2025

Sheffield Forgemasters recapitalisation plan boosted to £1.3bn

Ministry of Defence-owned Sheffield Forgemasters has seen its recapitalisation plan increase from £900m to £1.3bn to expand capacity and support manufacturing for defence programmes. Under the government’s announced increase in defence spending, the infrastructure at Sheffield Forgemasters has been challenged to meet additional demand for its unique output, with greater resilience, faster production, and reduced lead times.

The company supports UK sovereign production of nuclear submarine and warhead programmes through BAE Systems, Rolls-Royce Submarines, Babcock International and the UK’s Atomic Weapons Establishment.

The recapitalisation plan means the new forging line at Sheffield Forgemasters has been reconfigured, with increased capacity for furnaces, quench tanks and cranes, enabling the delivery of defence-critical submarine components more quickly.

Since the company was acquired by the MoD in 2021, the workforce has grown from 600 to more than 720, with the intake of apprentices now averaging 25 to 30 per year. Construction work on-site now employs more than 900 people, and more than 35% of the original £900m investment spend so far has been made in Yorkshire. The recapitalisation is also driving broader business transformation, delivering operational excellence and significant productivity improvements.

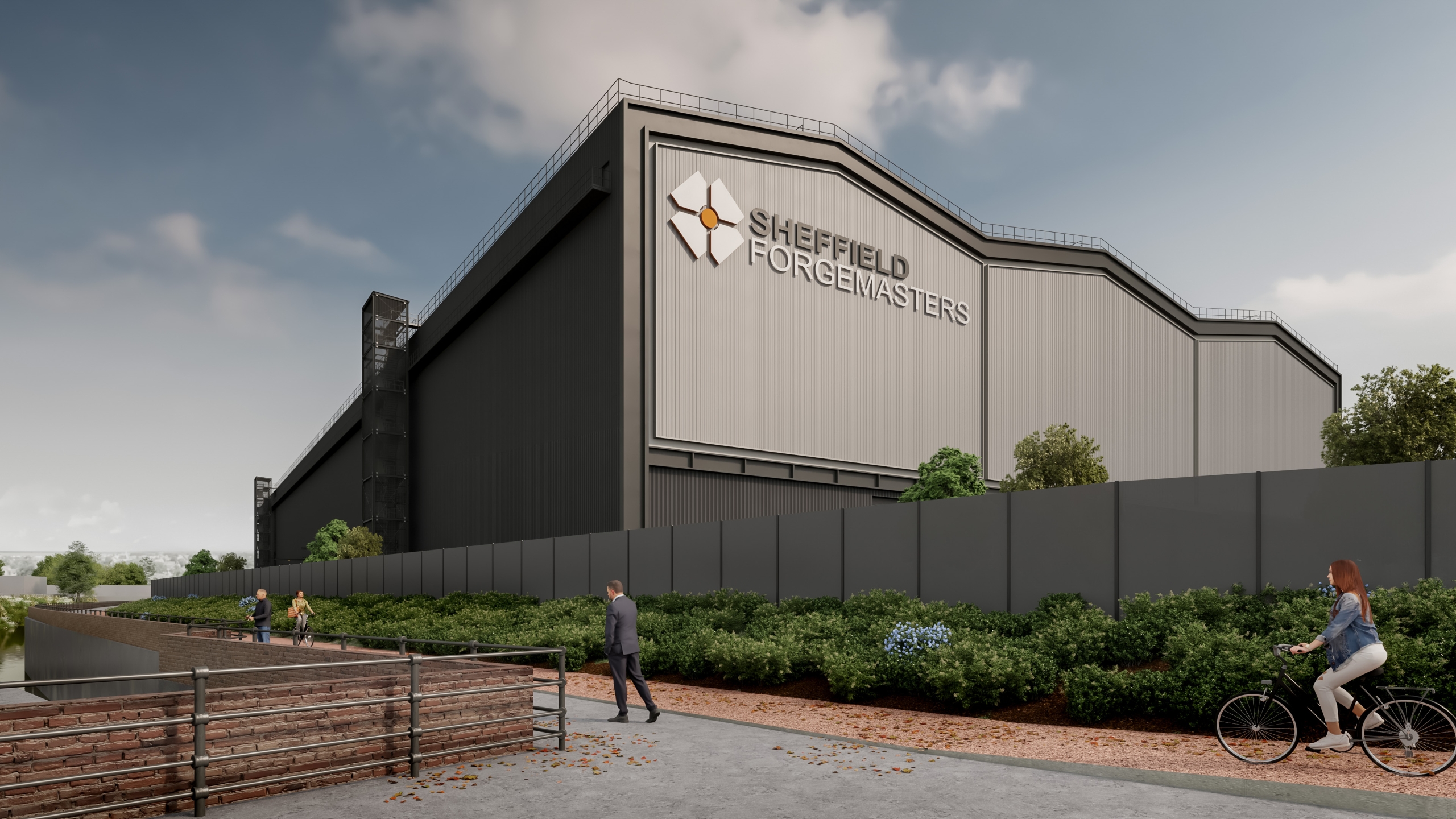

The Sheffield Forgemasters recapitalisation plan will increase from £900m to £1.3bn to expand capacity and support manufacturing for defence programmes the government has announced / Picture: Sheffield Forgemasters

Never miss the latest manufacturing news by signing up to our newsletter here

Gary Nutter, chief executive officer at Sheffield Forgemasters, said: “When the company was acquired by the MoD in 2021, the recapitalisation programme was in its infancy as we looked to upgrade our capability from legacy assets installed in the 1960s and 1970s. We originally aimed to use existing buildings to house new machinery, but as we explored increasing defence output, space became paramount, so we purchased an additional 21 acres of predominantly brownfield land to build a dedicated, new machining facility. The number of machines required to meet targets for the UK submarine programme has also grown to include 15 of the world’s most advanced, large vertical turning lathes, and associated equipment.”

The new forge and machine shop are set to be operational by the end of the decade, dramatically increasing the company’s efficiency and accuracy for some of the world’s most complex cast and forged products.

Picture: Sheffield Forgemasters

Gary added: “The volume of investment is an incredible story not just for Sheffield, but for the UK, with these facilities protecting hundreds of highly skilled engineering jobs for decades to come. We are well underway with the new forging line, with foundations almost completed and steelwork due to go up at the end of the year, and our new machine shop site has been prepared for piling work to begin. What is being created here is an incredible legacy for the UK and for our allies, and will play a fundamental role in the defence of our realm.”