2 minute read - 27th June 2025

Pilkington opens new glass production line in St Helens

Pilkington UK, part of the NSG Group, has launched a new glass production line at its Greengate Works site in St Helens as part of a multi-million pound investment to safeguard the future of rolled texture glass manufacturing in the UK.

The new rolled glass production line manufactures Pilkington UK’s textured glass range, featuring 21 original designs and textures used for privacy and style in interior design. Production of the range has been relocated to Greengate Works from nearby Watson Street Works, which ceased production last year after two centuries of pioneering glassmaking.

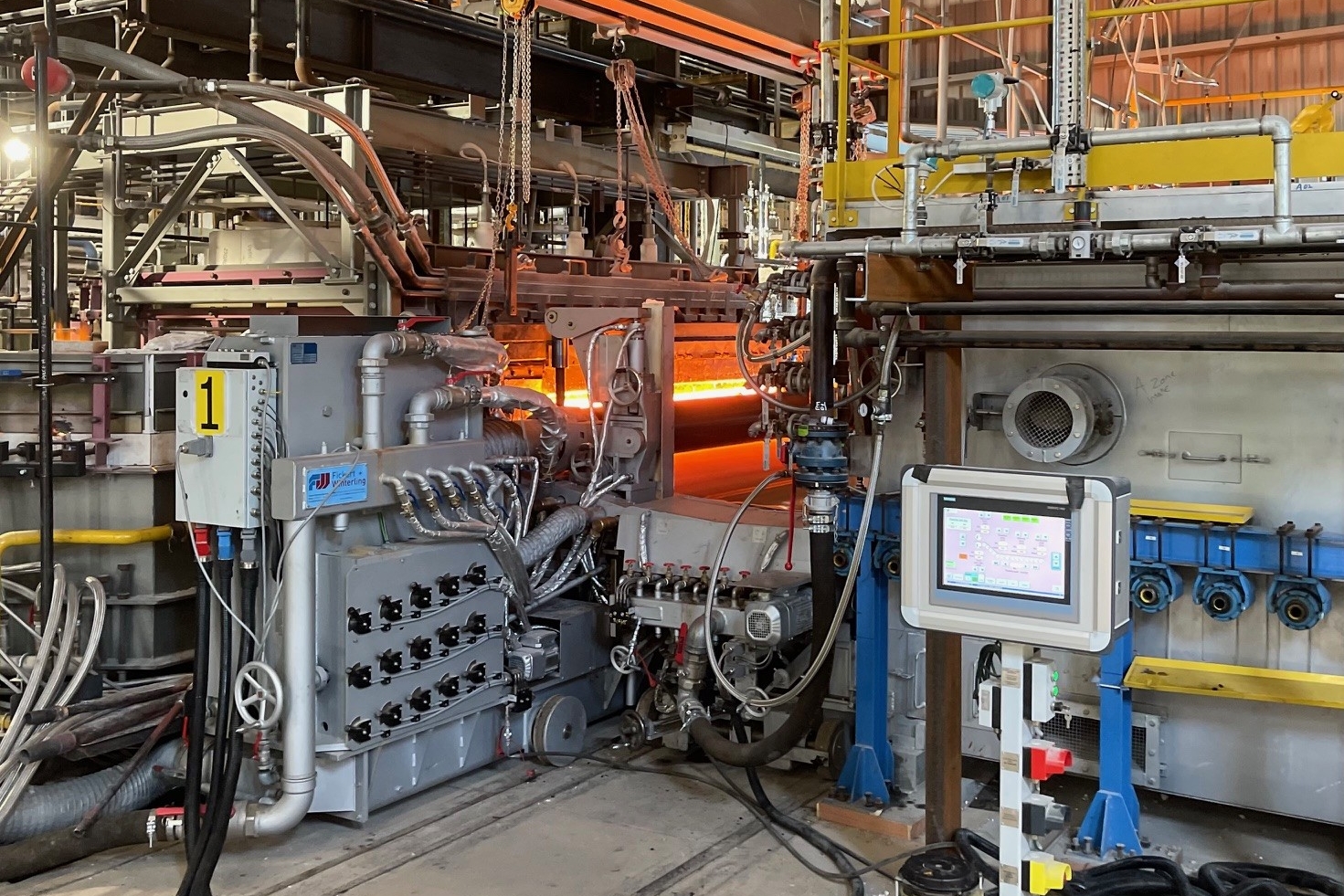

Pilkington has opened a new glass production line at its Greengate Works site in St Helens, enabling the company to save 15,000 tonnes of CO2 emissions annually / Picture: Pilkington UK

Never miss the latest manufacturing news by signing up to our newsletter here

Moving the production will enable the company to save 15,000 tonnes of CO2e annually, as Pilkington UK will now manufacture all glass from one furnace in the town, instead of the two between Greengate Works and Watson Street Works. Pilkington UK are supporting the council with plans to transform the Watson Street site.

Investing in the new line supports Pilkington UK’s wider sustainability goals, which include a 30% reduction in greenhouse gas emissions by 2030 compared to 2018 levels and achieving net zero by 2050. The upgrade received £3.7m in funding through the UK government’s Industrial Energy Transformation Fund (IETF), which supports industrial decarbonisation efforts.

The project completes the biggest investment in St Helens in decades and safeguards the future of rolled texture glass manufacturing in the UK / Picture: Pilkington UK

Neil Syder, managing director of Pilkington UK, said: “Texture by Pilkington has been manufactured by our team in St Helens since 1852 and we’re proud to continue that legacy with this new rolled glass line. It represents a meaningful step forward, not just in securing the future of texture glass manufacturing, but in significantly lowering the carbon footprint of the range. Its construction was an incredible feat of engineering too. To build the new line, our team needed to break into the side of a live glass furnace, constructing a canal that takes glass away from our current float line to the new rolled glass line in a separate building.

“This work now enables us to manufacture all our glass from one furnace, which saves us 15,000 tonnes of CO2e per year: the equivalent of taking over 8,800 cars off the road for a year. By investing in our Greengate Works site, we’re building on nearly 200 years of glassmaking heritage and innovation while positioning ourselves to meet the changing needs of our industry as it decarbonises.”