5 min read - 10 Feb, 2026

BMW marks 25 years of engine manufacturing at Hams Hall

BMW Group’s UK engine production facility, located in North Warwickshire, is marking a major milestone as it celebrates 25 years since the plant first opened and production began. Since 2001, its Hams Hall site has manufactured more than 7.6 million engines, alongside high-precision machining of key engine components.

The plant is a key part of BMW Group’s technology-open approach, supplying a number of the company’s production sites around the world with the latest generation of highly efficient petrol engines, including power units for plug-in hybrid models.

Today, engine production ranges from three and four-cylinder petrol engines to high-performance V8 engines, powering vehicles across both BMW and MINI.

Separately, the V12 engine is produced exclusively for Rolls-Royce Motor Cars. Its assembly follows a distinct, bespoke production process, carried out by specially trained production colleagues, before final delivery to the home of Rolls-Royce at Goodwood.

Dirk Dreher, head of BMW’s Hams Hall plant, said: “This anniversary is a special milestone for our site. We are a competitive plant and there’s always been a real passion among our workforce to continually improve our manufacturing processes and site. Building on our strong foundation, we are looking forward to remaining a successful plant in the future.”

A history synonymous with efficiency and growth

Over 25 years, the plant has built a robust record of efficiency and growth, manufacturing engines using the very latest technology for some of the most iconic BMW Group vehicles. From producing just one engine family in 2001, the plant now manufactures two different engine families, with the recent integration of V8 and V12 engines bringing a higher business value to the plant.

There has also been significant growth in the plant’s high-precision machining business, too. Originally only producing for the plant’s own engine production, the machining facility expanded over the last decade, trebling its capacity, increasing annual production to more than a million components, and extending supply to BMW Group’s engine manufacturing plant in Steyr, Austria.

Harald Gottsche, head of engine production at BMW AG, added: “The Hams Hall plant is an integral part of our global production network. The site combines technological expertise with high flexibility. It reliably supplies our vehicle plants with efficient, powerful engines of premium quality. This includes the V12 engine – a masterpiece from Hams Hall!”

As the quarter-century milestone is marked, the focus on applying BMW iFactory manufacturing principles – a holistic and forward-looking production strategy – to be efficient, sustainable and digital, is already firmly embedded as the plant embarks on its next chapter.

A systematic approach to reducing energy use

From the first concept of the plant to the present day, the Hams Hall team has made sustainability a key consideration. Since the first full year of production, the plant has made a 61% reduction in energy required per engine built, meaning the overall energy to operate the site has remained level even though there has been a considerable increase in production. The plant purchases 100% of its external electricity from renewable energy sources today. It has also worked to reduce its consumption of natural gas.

A journey of digital transformation

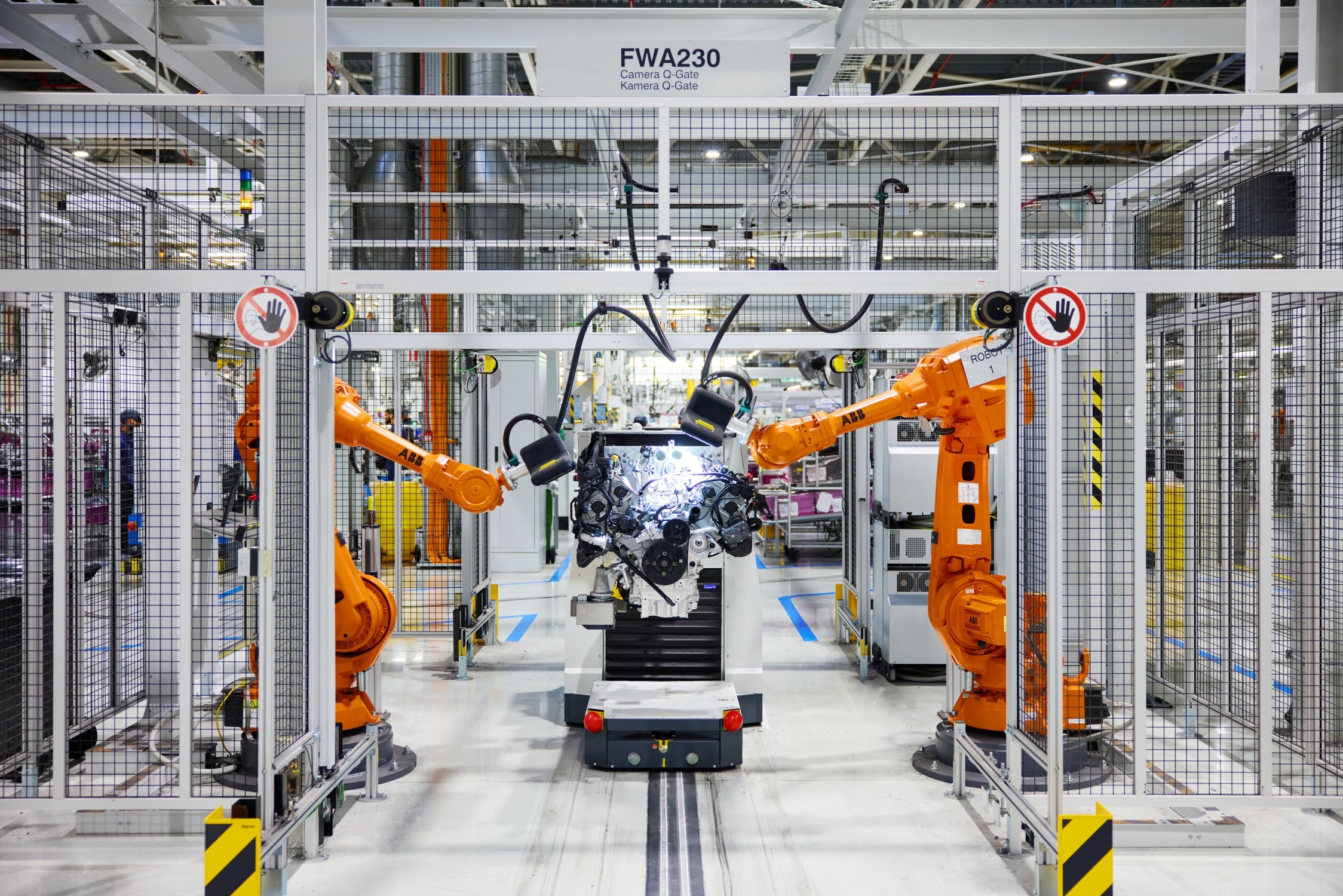

Several digital advancements are already delivering tangible benefits, bringing further efficiencies and ensuring the plant is fit for the future. At the heart of the digital transformation is the plant’s fully-connected digital twin, comprising three layers: a 3D representation of the plant, a data layer that brings together information in one centralised place, and an application layer that helps make sense of the data and provides a precise, real-time bird’s-eye view of the plant’s operations. A range of systems and tools feed into the digital twin, including the plant’s four-legged team member – an autonomous robotic dog – equipped with visual, thermal and acoustic sensors deployed to perform various maintenance tasks.

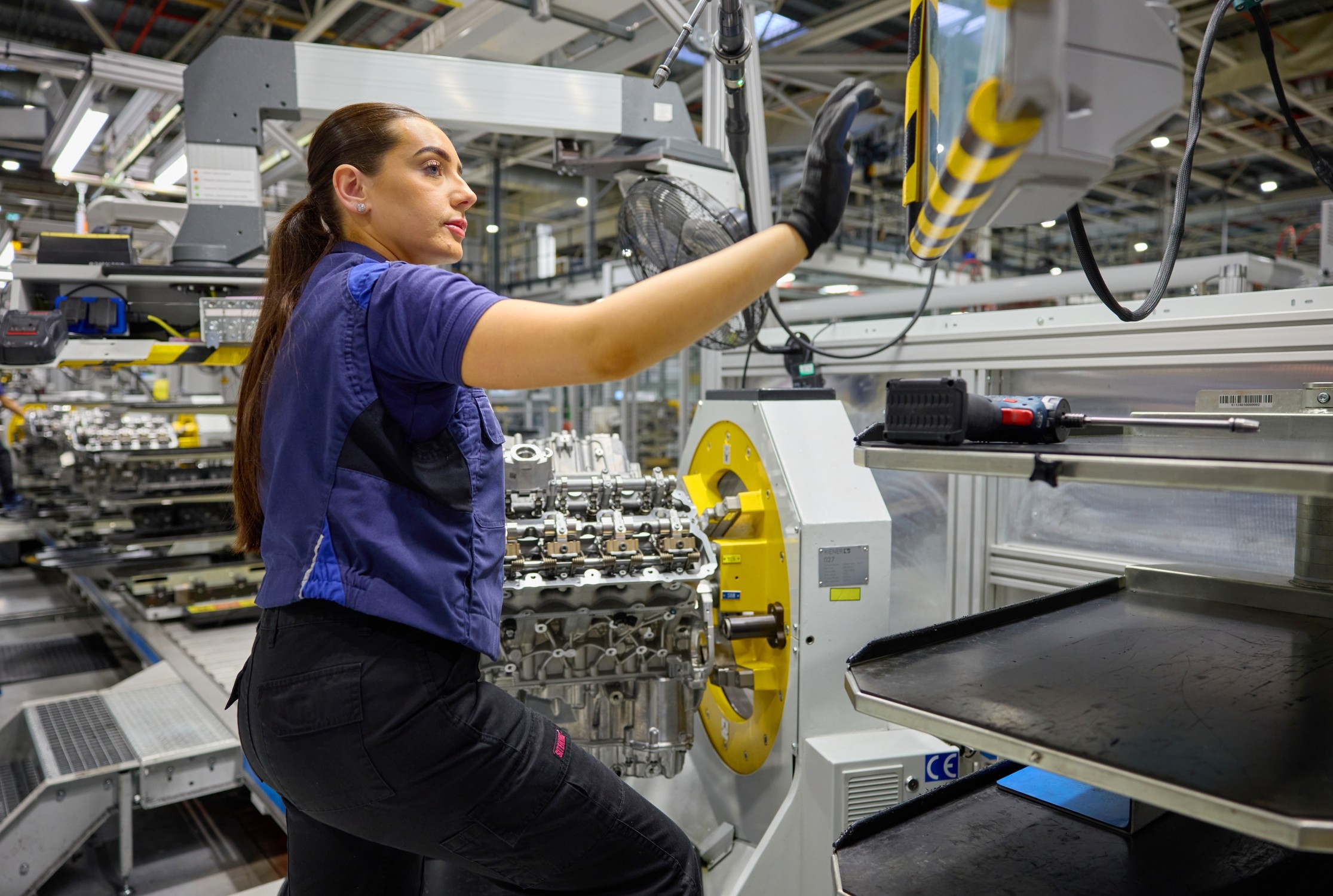

Within the V engine production system, autonomous robots have been integrated to assist in the movement of engines and worker guidance is digitised at every workstation. Other advancements, such as the implementation of AI camera technology, are proving critical in the pursuit of absolute quality and increasing the speed at which potential quality topics can be detected.

Efficiencies driven by people

The plant has a strong continuous improvement culture – a key part of the value-added production system – where people go the extra mile to reduce waste, avoid unnecessary costs and save money. ‘Fresh Thinking’ is an active initiative driven by the people closest to the day-to-day work, going beyond standard company-wide efficiency programmes. Often, it is about noticing the small details, finding better ways of working or questioning the status quo. A workforce engaged on these topics delivers hundreds of ideas to achieve significant savings.

Key milestones

2001: The first brand new four-cylinder BMW engines were built at the plant in 2001, marking the start of series production at Hams Hall. VALVETRONIC technology was integrated into volume production for the first time to deliver significant decreases in fuel consumption and lower engine emissions.

2006: Further growth came in 2006 with an additional new engine family, which expanded the plant’s customer base to MINI, supporting a raft of updates to the brand that improved the fuel consumption and emissions of the iconic car.

2013 – 2015: The plant saw further investment across the site and began integrating another new generation of engines. The Hams Hall plant became the sole supplier of the three-cylinder engine for the BMW i8 plug-in hybrid sports car. Production of this engine family continued to expand in 2015, with additional three and four-cylinder petrol engines integrated for MINI and BMW.

Alongside engine assembly, a high-tech machining hall producing crankshafts, cylinder blocks and cylinder heads is a core part of the Hams Hall site. Around the same time, investment also extended to a complete overhaul of this facility, trebling its capacity and increasing annual production to more than a million components for engines built at both Hams Hall and supplied to the BMW Group engine manufacturing plant in Steyr, Austria.

2022- 2023: A new production facility was integrated into the assembly hall, increasing the plant’s business value when production of the company’s V engines (V8 and V12) was entrusted to the plant. V12 engines from Hams Hall are supplied for Rolls-Royce Motor Cars, with V8 engines built for various models, including a plug-in hybrid variant for the BMW M5 Saloon and Touring.

2026: The Hams Hall plant reaches its quarter-of-a-century, 25-year milestone.

All pictures courtesy of BMW Group.