1 minute read

Aeromet secure backing for additive manufacturing project

A group of innovative companies led by Aeromet International have been awarded funding from the National Aerospace Technology Exploitation Programme (NATEP) to further develop the innovative A20X™ advanced aluminium powder for additive manufacturing.

As part of the High Strength Aluminium Powder for Additive Manufacture project Aeromet, along with partners Renishaw, Rolls-Royce and PSI, are set to further optimise the A20X™ alloy for use in additive manufacturing and produce a set of demonstrator parts.

NATEP, an Aerospace Growth Partnership initiative, is an industry-led programme supporting UK-wide companies in the aerospace supply chain to develop innovative technologies.

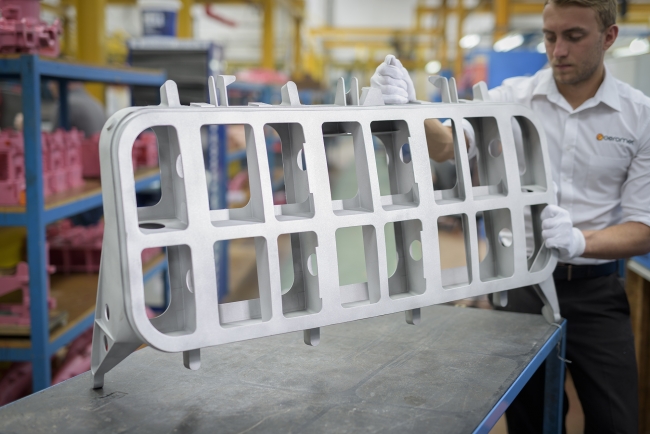

Aeromet manufacture aluminium and magnesium cast metal parts for the aerospace and defence industries / Picture: Aeromet

Mike Bond, Director of Advanced Material Technology at Aeromet, said: “We are very pleased to have been awarded NATEP funding for this exciting project. By working with our partners, we hope to further develop our powder technology and create a new option for high strength additive manufactured parts. NATEP is a great way for innovative companies to come together to develop cutting edge technologies”.

A20X™ is a family of next generation high-strength aluminium alloy technologies, developed and patented by Aeromet. The A20X™ family includes the Metallic Materials Properties Development and Standardisation (MMPDS) approved A205 casting alloy and A20X™ powder for additive manufacturing. A20X™ is an aluminium-copper alloy with a highly-refined microstructure and a unique solidification mechanism, giving it greater strength, fatigue and thermal characteristics compared to other alloys. A20X™ castings are already in production for high strength, high temperature aerospace applications and the HighSAP project aims to exploit the potential of A20X™ for additive manufacturing.

Paul Murray, Principal Materials Engineer at Rolls-Royce, added: “Rolls-Royce are excited to participate in this project and contribute to the development of this very promising new aluminium alloy. NATEP is a proven programme with a strong track record of supporting innovation in the UK aerospace supply chain”.

Aeromet has developed and patented the world’s strongest commercially available aluminium casting alloy, A20X™, which is the first new aluminium alloy brought to market for the aerospace industry in over 40 years / Picture: Aeromet