2 min read • published in partnership with Atlas Copco

Atlas Copco launches vibration analysis service

Compressed air is the backbone of many workshops and production environments, and any interruption can have a knock-on effect on schedules, output and costs. By adopting vibration analysis as part of condition-based maintenance, engineering and operations teams can protect productivity and extend the life of their assets.

In a boost to day-to-day plant reliability, Atlas Copco has introduced a vibration analysis service for industrial air compressors, enabling UK manufacturers who rely on compressed air to detect hidden mechanical issues before they lead to unplanned downtime, excessive energy consumption or expensive repairs.

The new service provides fast, on-site diagnostics using advanced vibration measurement tools. In just two minutes, Atlas Copco specialists can identify early warning signs of problems such as bearing wear, rotor instability, misalignment or imbalance, without interrupting operations.

“Unexpected downtime and rising energy bills are among the costliest risks for industrial operators today,” said Ben John, Business Line Manager Industrial Air from Atlas Copco. “Our new vibration analysis service gives customers valuable insight into their compressor’s condition so they can act before minor issues become major failures.”

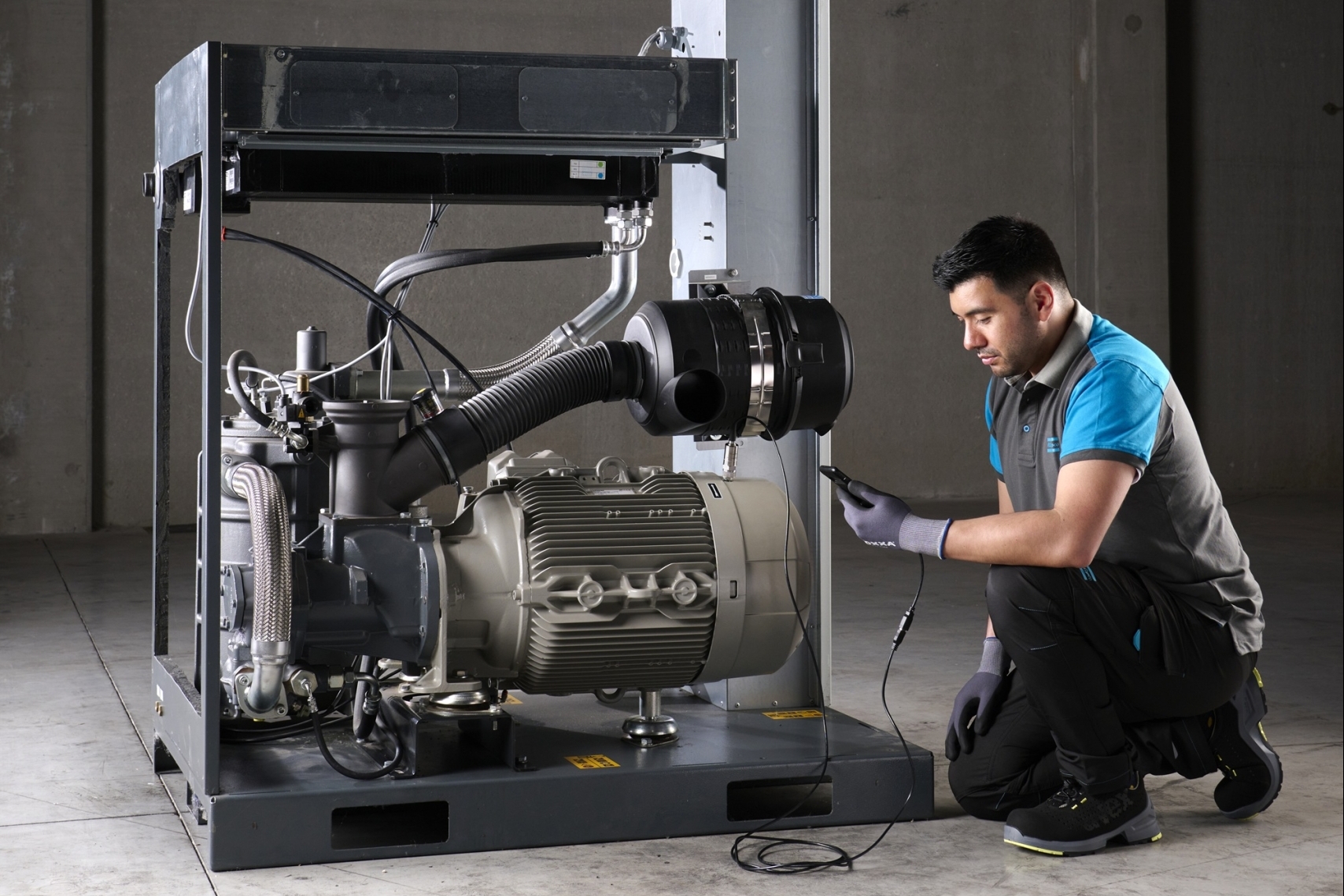

By adopting vibration analysis as part of condition-based maintenance, engineering teams can strengthen reliability programmes, protect productivity, and extend asset life / Picture: Atlas Copco

Unlike some vibration monitoring solutions, that can cost thousands of pounds and require equipment shutdown, Atlas Copco’s service takes place while the compressor is running. The assessment is carried out by trained technicians using industry-leading diagnostic equipment. Customers then receive a detailed report outlining any concerns and recommended next steps.

Vibration is one of the most reliable indicators of mechanical wear. Left unmonitored, excessive vibration can reduce compressor lifespan, impair system performance, and increase energy usage. Studies show that a misaligned or inefficient compressor can consume up to 20% more energy than a properly maintained unit.

The service is suitable for compressors used across a wide range of industries, including manufacturing, oil and gas, food production, and pharmaceuticals. It supports condition-based maintenance strategies, helping customers reduce total cost of ownership while improving equipment reliability and workplace safety.

Atlas Copco’s vibration analysis forms part of its broader commitment to helping customers maximise uptime and efficiency through proactive service support and data-driven insights.

For more information or to schedule a vibration analysis, visit the website here.