5 min read • published in partnership with PP C&A

Case study: Cheers! EBar and PP C&A partner to scale Beerwall® production

One of the hospitality sector’s most significant innovations has been given a production boost thanks to the scale and outsourcing capabilities of PP Control & Automation (PP C&A).

The best inventions are often born out of necessity, and that is certainly true of EBar, which is transforming bar service at live venues and sporting events across the UK.

Like any self-respecting rugby supporter, EBar co-founder Sam Pettipher was waiting in a lengthy queue for a half-time pint at a Six Nations international, when the match restarted and he missed seeing a crucial try. This got him thinking that there must be a better solution to speed up bar service, the kernel of an idea that was accelerated when he joined forces with Nick Beeson during their MBA course at Robert Gordon University in Aberdeen.

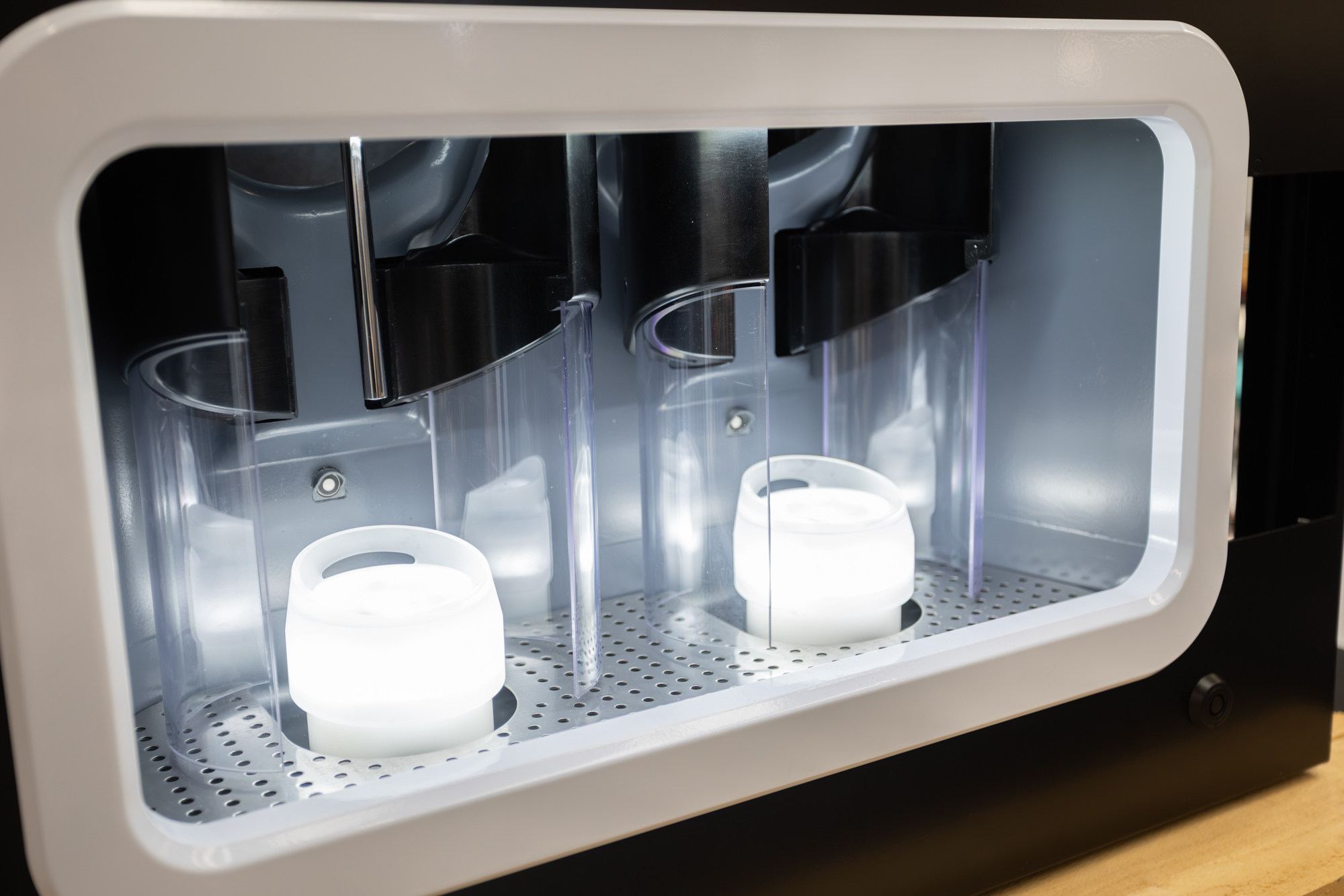

Fast-forward nine years and EBar® is the fastest growing automated self-serve drinks solution in the UK, serving perfect pints in seconds. In fact, the firm’s patented pressure pour technology delivers 98% keg optimisation and is capable of pouring 200 pints per hour. This, along with its simple three-step ‘order, pay, pour’ interface, are proving a major hit not only with event goers, music lovers and sports fans, but also with venue operators keen to improve service and maximise revenue.

The scenario

The first product to enter the commercial marketplace was the mobile EBar®, which can be deployed and set up at venues in just 30 minutes. This was designed, developed and initially built in-house until assembly was outsourced to a local partner.

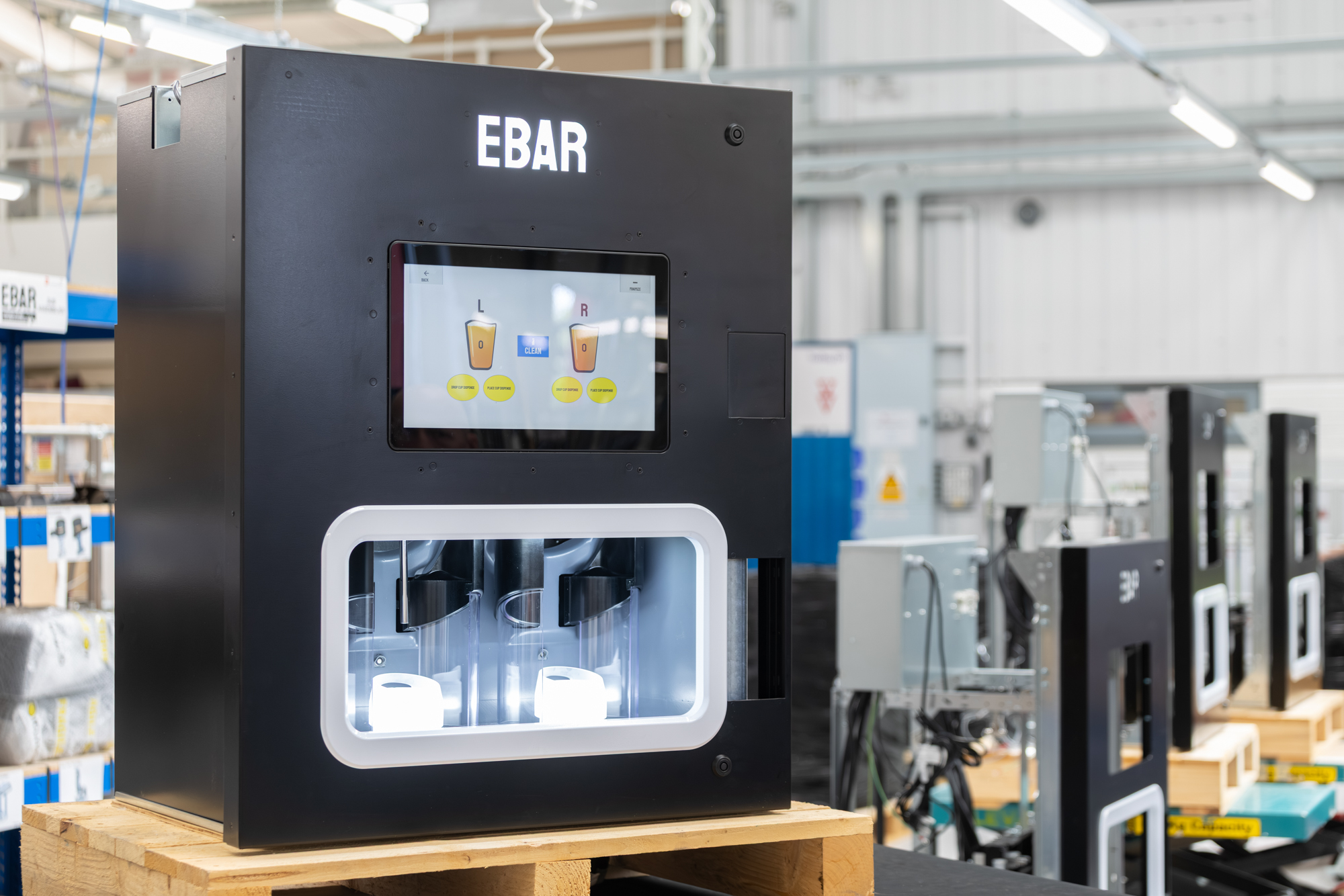

Demand for this technology has grown rapidly, and in 2023, the company introduced its latest solution – the Beerwall®. This is a permanent installation capable of pouring 400 pints per hour in a 2-unit configuration and has already been adopted by Brighton Hove Albion FC and five other Premier League clubs.

“Fan reaction is really driving our expansion and building our reputation for delivering a truly frictionless bar service solution for venues,” explained Nick Beeson, managing director at EBar.

“We are innovators, not manufacturers, and we recognised that volumes were going to quickly outgrow the capabilities of our first assembler.”

“Managing the supply chain was very labour-intensive, which accelerated our decision to look for an outsourcing partner who could give us the ability to scale-up quickly and, importantly, get our products to market in a timeframe that suited the customer. Giving someone else responsibility for building our core product was a pivotal business decision that we knew we had to get right.”

The solution

After an extensive procurement process and several site visits, PP Control & Automation (PP C&A) was chosen as EBar’s outsourcing partner, with the automated drink dispensing specialist initially giving it responsibility for scaling-up production of Beerwall®. This involved the complete electronics and mechanical build and full assembly of the state-of-the-art model at PP C&A’s facility in the West Midlands.

A dedicated team of eight engineers have created a specialist production cell that has the potential to build up to five units every week, a 200% increase on the previous capacity. Investment in the latest automated crimp technology has also eliminated poor wiring connectivity that had delayed previous machines, whilst several issues with supply chain lead times have been collaboratively overcome with subtle design and procurement changes.

Nick went on to add: “The new product introduction process has been a fantastic opportunity for us to streamline some parts of the build and explore different components that can speed things up. Working with the PP C&A NPI team has seen us reduce ‘production’ of a Beerwall® to two days and this gives us confidence that we can scale up to the expected five units per week by the middle of summer.

“The outsourcing process has been quick and relatively straightforward and allowed us to focus on both new R&D activities and capitalising on commercial opportunities that will increase the number of Beerwall® units in operation to 100 by the end of 2025.”

The PP C&A difference

Constant investment in automation has been a key strategy for PP Control & Automation for the last two decades, and this has created one of the most productive factories in the UK.

One of the major issues in the initial EBar build was the wiring loom, which could take up to half a day of production time. Utilising the power and speed of the Komax Zeta 640 harness machine, PP C&A has reduced this process to just minutes, delivering a huge time saving whilst also improving on repeatable quality.

“Outsourcing is about understanding the bigger picture – the pain points, the end goal and what looks like success…these are all conversations we had with Nick and his engineering team,” pointed out Matt Heather, business development manager at PP C&A.

“Complexity of the supply chain was one of the big things that came out of these discussions. There was a dependence on certain suppliers, and managing lead times was a constant source of frustration.”

He continued: “We’ve taken this type of anxiety away from other clients in the past and suggested that we take over the full management of the supply chain. There were existing relationships with a lot of the component suppliers, so the handover was seamless, and we’ve been able to cut lead times on troublesome parts due to greater visibility and communication.”

The results

Two units per week were built during the initial production phase, but six months into the outsourcing partnership, with systems and processes in place, production of the Beerwall® is hitting the target of producing five units per week.

Build time has been cut in half and right first-time rates have improved significantly, meaning EBar has full confidence in the performance of its technology when it rolls into a commercial setting.

Supply chain management concerns have been minimised by giving full responsibility to PP C&A, with new components identified for future builds that could save money and time. Engineers from both teams continue to work with full transparency to identify other assembly improvements and to explore how the latest technology addition – the automatic cup feeder – can be integrated into future builds.

Nick said: “The last twelve months have been transformational for EBar. We’ve proven that our automated drink dispensing technology works at major live events, and we’re now ready to capitalise on a significant increase in orders for our Beerwall® range. Our outsourcing relationship gives us the manufacturing confidence that we will meet current order times, as well as having the scale-up capability to ramp production to hundreds of Beerwall® units each year.

“There is also the international marketplace to consider, and this is something we could initially serve from the UK, especially with PP Control & Automation holding UL508a certification which is ideal for the North American market.”

PP C&A’s Matt Heather concluded: “EBar is delivering one of the biggest hospitality innovations in decades and we are giving it the production capability to maximise its first-to-market opportunity. It’s fantastic to see two domestic innovators actually commercialising the technology in the UK.”