3 minute read • published in partnership with igus

Case Study: igus helps machinery manufacturer increase throughput for packaging machinery

A packaging and processing machinery builder has reduced drag, improved rigidity, increased throughput and raised hygiene standards on one machine family by applying an iglidur IC-05 tribo-coating on a mitre bar application.

Machine manufacturer Doel Engineering designs and builds a very wide range of processing machines, often in small batches or one-offs. To plan production efficiently, the machines need to work correctly as designed, running accurately with high throughput and minimum adjustments and issues.

A pad seeker machine takes bubble wrap and/or food tray liner material from a web, stretches and cuts it in sections for placement in plastic trays. An igus drylin Y linear rail system moves tension rollers in two axes, back and forth and up and down, to manipulate the web. Doel Engineering had used hollow rollers for this process, but they failed to apply adequate tension in the material for an accurate, high rate cut and throughput was low. In addition, after stopping the operation the rollers would continue to spin or run-on, having inertia, which meant waiting for the roller to slow or stop, before the next cycle could start, reducing productivity.

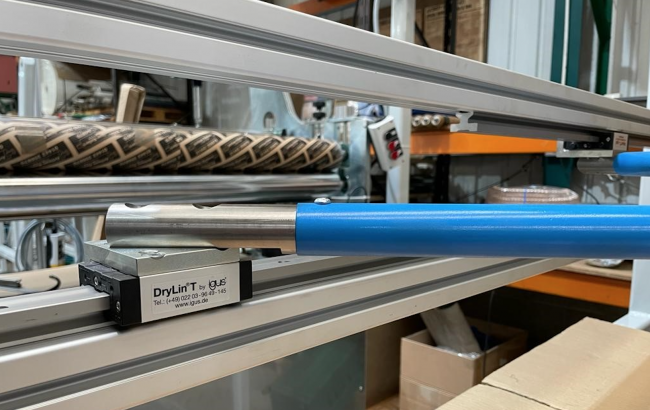

igus has helped machinery manufacturer Doel Engineering reduce drag, improve rigidity and increase throughput of its packaging machinery / Picture: igus

igus evaluated the process with production manager Adam Deighton and recommended replacing the rollers with solid metal bars coated with iglidur IC-05, an FDA-approved tribologically optimised polymer in powder form.

The newly coated bars have several benefits. Being solid not hollow, the bars have better rigidity, so the machine performs better, running smoother and faster using the more solid components. They exhibit zero run-on and the start / stop operation is instant, increasing throughput. The IC-05 coating protects the bar substrate, reducing wear – like all iglidur materials, iglidur IC-05 coating powders are tribologically optimised and provide excellent friction and wear values.

In addition, this 60 -100 micron coating is FDA-approved, i.e., verified as safe for the food industry with no risk of contamination, and blue in colour for visibility. The previous rollers made of non-coated metallic material carry the potential risk of contaminating the absorbent pack, despite regular cleaning of the machine. The IC-05 coating will not expose any bare metal to food reducing the chance of oxidising food products like meat.

The very thin powder coating allows the user to protect even heavily used surfaces from wear and tear – without using any additional components.

“The mitre bar application has proved to be one of the more difficult areas for one of our machines – although we have workarounds for this, the idea of tribo-coating the mitre bars was really appealing,” says Adam. “It enables us to continue with the smooth linear adjustment provided by the drylin T linear bearing system and then use solid bars, which offer better strength and rigidity over a roller solution. With a coating of just 100 microns, it also means we did not need to change the parts being used previously and could offer an upgrade to those already out in the field.

igus helps manufacturing and engineering businesses address challenges, solve problems and improve the efficiency and productivity of their equipment / Picture: igus

Adam concluded: “The results are a smoother running material feel, higher speed and with less wear to both the shafts and the materials being handled. The solution is a very affordable price point, on a fast turnaround and something I will consider in the other areas of our equipment.”

The precise engineering challenge

On the pad seeker, the material comes in from one direction and gets diverted “off course” using a ground bar run on drylin linear bearings. Another pair of bearings move the second machined bar in to position so the web of material aligns. The length of the bar and the stroke of the drylin T bearing system makes it easier to position the web and adjust for different material widths. The user can adjust the dimensions of this for specific products within their line or allowing for complete product diversification.

The igus IC-05 coated bar solution remains lock solid between the two carriages of the bearings that provide that low friction bearing movement. Product Manager at igus, Dean Aylott, says: “The material runs over these tubes at high speed and for long periods. By replacing the standard ground bar with a wear-resistant coated bar we are reducing the friction and drag, enabling the user to maintain the tension in the material but without the ‘run on’ created by a roller solution.