5 minute read • published in partnership with MRPeasy

Case Study: Nanomaterials developer gains layers of control with MRP software

UK-based nanomaterials developer Advanced Material Development prides itself as “a provider of nano-scale solutions to world-scale challenges.” This case study looks at how AMD scaled new heights in traceability and bill of materials (BOM) management through MRP software.

Providing nano-scale solutions to world-scale challenges

Advanced Material Development (AMD) is an early-stage UK company established in 2018. The company develops ways to exploit the value of nanomaterials and integrate them into conventional material systems for high-performance applications in several business sectors. Working closely with universities, researchers, private companies, and public authorities, AMD facilitates cooperation between academia, private corporations, and public entities.

AMD’s primary focus of research is in 2-dimensional nanomaterials such as graphene. The array of products and concepts under development include conductive inks, photonic crystals, advanced sensors, and many more. Catering to a variety of sectors, AMD works closely with the automotive, aerospace, defence, and food industries. Today, the company boasts a team of 10 full-time staff and a network of specialised subcontractors.

AMD’s business model is as innovative as its products. It aims to bring together the various stakeholders to accelerate and build the nanomaterial ecosystem around the technology, society, and business. By partnering with top-tier academic institutions such as University of Surrey and University of Sussex, as well as a roster of contracted researchers, AMD bridges the gap between research, societal needs, and commercial viability, and paves the way towards real-world application and commercialisation.

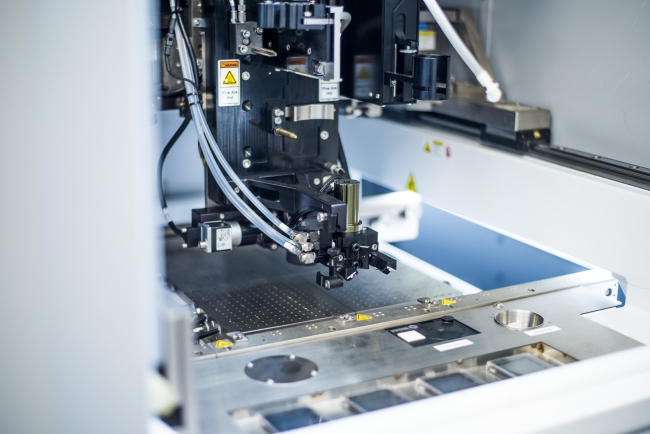

Picture: AMD

Challenges in traceability and BOM control necessitated a search for productivity software.

With a plethora of complex formulations simultaneously in development, AMD’s inventory and production management needs have mostly been informed by a high degree of control over its bills of materials, item costing, and customer relationships. Up until 2022, spreadsheet programs were used to keep track of the various formulations. However, as the company expanded, these fell short in offering the traceability, version control, and logging of the intellectual property that AMD’s operations demanded.

Tasked with finding a viable software solution was AMD’s Director of Program Management, James Johnstone. “We had information littered everywhere. We needed a system that could keep track of our formulations and accurately calculate and track their costs,” he says. James scoured the web and came up with two distinct options – a bills of materials management app Open BOM, and manufacturing software MRPeasy.

Deciding between these two systems fell to Niamh Cooper, a Physics student from Surrey University, who was completing her placement at AMD at the time. Niamh carried out a comprehensive business analysis for the two systems and found Open BOM to be a lot more basic compared to MRPeasy. “Whilst Open BOM provided some of the functionality AMD was looking for, it was like a recipe book, whereas MRPeasy could take AMD from end-to-end of the whole production management cycle, including shipping and traceability,” Niamh says, and adds: “It also had a lot more learning resources and a great support team. This proved instrumental in choosing the software.”

Emphasising the importance of thorough implementation

Implementing an MRP system needs a lot of concentrated effort. Being first and foremost a research company, many of AMD’s staff were not acquainted with manufacturing software or its potential utility. It came as a stroke of good luck, then, that Niamh was on placement at AMD at the time. “We were lucky that we had someone dedicated to assessing the software, instead of making it a side-task for someone with a lot of stuff going on,” James comments.

While AMD’s management recognised the importance of the new software, ensuring that everyone on the team understood its significance required an effort. This underlines the importance of getting all stakeholders truly on board with an MRP system before implementation, as successful implementation, is not just a technical task, it also can require a cultural shift.

Thankfully, the implementation team got acquainted with the software and set clear priorities as to which functionalities to roll out first. In AMD’s case, it was the bills of materials functionality and setting up an effective traceability system.

As James puts it: “Since the company deals with intellectual property mostly, the formulations are very much a part of our value. Knowing which formulations went to who and logging all of them is paramount for us. Implementing that has taken around six months and today we’re pretty happy with where we’re at.”

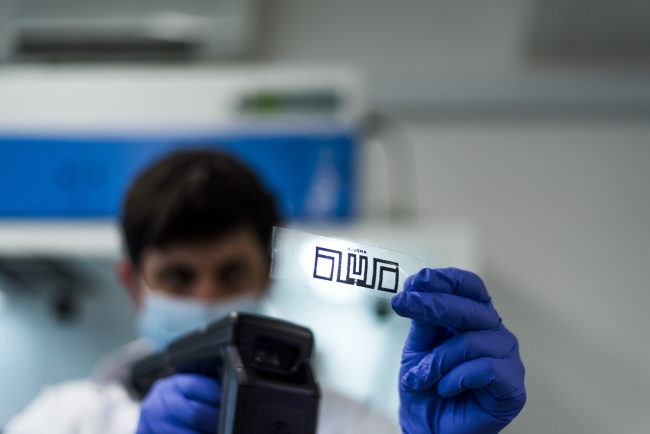

Picture: AMD

Rising confidence in manufacturing practices

While not the most usual MRP software client, today AMD is successfully using MRPeasy in a number of ways. Huge strides have been made in organising and logging the company’s intellectual property through the software’s intricate Matrix BOM functionality. In addition, MRPeasy has been a big help in defining product routings, associating manufacturing costs, and ensuring sufficient levels of traceability, especially vital for the company’s clientele in the defence sector.

James asserts: “MRPeasy has provided us with a foundation and given us the confidence and ability to ship well defined, quality assured products to customers along with the traceability required for our demanding customer environment. One of the challenges in the nanomaterial community is turning complex materials, know-how and processes into a sellable product, so a lot of the work fundamentally revolves around logging what you are doing and getting the customer facing end of the business disciplined. MRPeasy is helping us with the commercialisation and industrialisation of these work process.”

With a wealth of experience in the fast-growing market of nanomaterial applications, AMD has a bright future ahead of itself. Thanks to a reliable productivity software companion in MRPeasy, this fast-growing UK company has managed to gain a new level of control over its intellectual property and is extending its newfound operational prowess to other facets of manufacturing.

MRPeasy is a manufacturing ERP software for small businesses with 10-200 employees. MRPeasy users report a 54% average improvement in the overall performance of their company and a 42% increase in on-time deliveries. More information and a free trial are available at MPReasy.com