2 minute read • published in partnership with MRPeasy

Case study: Precision engineering company cuts administrative load by 70% with MRPeasy

EGL Vaughan is a CNC milling and turning company with a 40-year legacy and is now a frontrunner in the UK’s precision machining sector. The company, which has recently been acquired by the multinational engineering group, Allied Global Engineering, delivers top-tier, precision-engineered parts to both domestic and international markets.

The path to precision – implementing MRPeasy

Up until the change in ownership, EGL Vaughan used Excel spreadsheets for its production and inventory management. However, Allied Global’s Director of Operations, Jan-Marc Pickhan promptly recognised the need to implement manufacturing software which could boost efficiency and offer system-wide traceability without breaking the bank. MRPeasy was chosen for cost-effectiveness and ease of implementation.

As MRPeasy is purpose-built to be self-implemented, Jan-Marc took the process upon himself, bringing the software’s basic functionalities online in June 2023. He then imported and created production data like stock items and bills of materials to the system over the next 2 weeks.

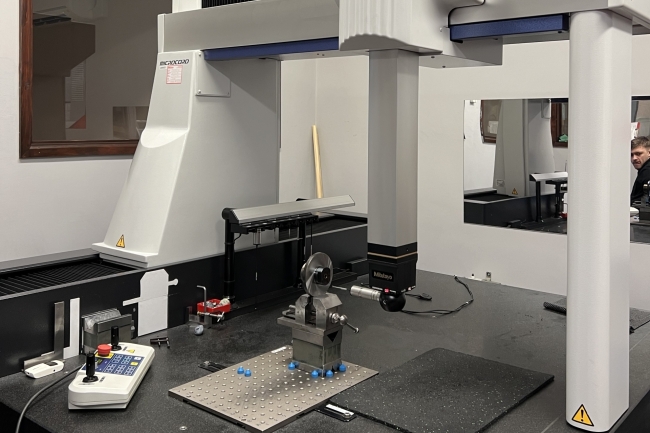

Picture: EGL Vaughan

Despite some initial challenges brought on by the rapid pace of transition, the staff adapted to the new system quite well. Instrumental in helping to ease the transformation were employee training and the incremental nature in which MRPeasy’s features were adopted. The spreadsheets were phased out gradually as from a specific time onwards, new manufacturing orders were entered on MRPeasy, while existing ones were allowed to be completed using the old system.

Administrative load cut by 70%

Shifting from manual data entry to the data management capability of a unified cloud-based system has boosted EGL Vaughan’s operational efficiency over a short span of time. “It used to take at least 2 hours to launch something into production just because of all the data that had to be transferred in Excel. Because we did not have a sophisticated system, it was a lot of manual data moving and that’s just asking for trouble. With MRPeasy, converting quotes to manufacturing orders and sending purchase orders to suppliers, is done within minutes, dramatically reducing setup times,” explained Jan-Marc.

MRPeasy is also enhancing EGL Vaughan’s traceability, production scheduling, increasing capacity planning accuracy and on time delivery rate, and has simplified managing the company’s many subcontractors. Overall, it has reduced EGL Vaughan’s administrative load by as much as 70% in the short span of time since its implementation in mid-2023.

Positioning for sustainable growth

Jan-Marc Pickhan is convinced that as EGL Vaughan’s use-case of MRPeasy gradually grows and more functionalities are implemented, operational efficiency gains will be felt well into the future. He is also looking forward to implementing the software in one of the parent company’s other recently acquired subsidiaries, Mantec Engineering Limited, and enabling MRPeasy’s multiple production sites and facilities functionality.

MRPeasy is a manufacturing ERP software for small businesses with 10-200 employees. MRPeasy users report a 54% average improvement in the overall performance of their company and a 42% increase in on-time deliveries. More information and a free trial are available at MPReasy.com