5 minute read • published in partnership with Kawasaki Robotics

Case Study: Single robot with a six station process helps improve capacity and quality

Manufacturers use automation to take their operations to the next level. Whether it is increasing throughput or decreasing labour costs, the integration of robotics gives enterprises of all sizes the opportunity to expand their business and eliminate pain points in their processes, which oftentimes has a ripple effect of unforeseen benefits.

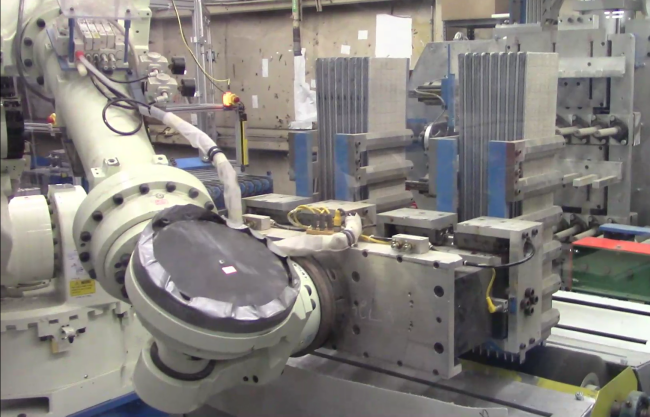

When Battery Builders, LLC. (BBI), a US-based industrial lead-acid battery manufacturer, decided to upgrade its facility, it seemed like an obvious choice to include a six-station COS (Cast-On-Strap) machine in those upgrades. It worked with robotic integrator MAC Engineering from Benton Harbor, MI to install a Kawasaki large payload robot with a robotic cell consisting of 6 process stations. Almost immediately after installing the robot, Battery Builders saw a more consistent product – an unforeseen benefit that will likely have a huge impact on its business.

Picture: Kawasaki Robotics

The Challenges

• Precise, versatile robot needed to tend machine types

• Decrease number of operators needed

• Increase throughput and product quality

The robot needed to have a high payload and high repeatability in order to lift and align the battery plates accurately. BBI also needed to be able to rely on their robot and peripheral equipment to meet production goals of 1,000 battery cells per day – more than double their current daily production – using less manpower.

Top Priority: Reliability

BBI was plagued by frequent machine breakdowns from their manually run COS machine, which they had for over 25 years. The antiquated machine was causing delays in production – BBI was experiencing four to five hours of downtime a week.

Health & Safety Risks

The process of manually stacking battery plates and loading plates into jars generated more airborne lead dust, which posed a greater risk for exposure than if the process was automated. The older machine also required employees to lift heavier loads, resulting in a greater risk of injury. For BBI, it was important to see the positive impact of automation reflected in their work environment – not just on their bottom line.

One Robot, Six Stations

In order to properly create their lead-acid batteries, BBI had to install a workhorse precise enough to consistently align 300 lbs. of battery plates up to 500 times per day. The robot also needed to be able to brush off the end connectors on the batteries, dip them into molten lead, and package them in a plastic jar, among other tasks. In order to accomplish this diverse list of detailed tasks, they needed a versatile robot.

Streamline Operations & Redeploy Employees

One of the manufacturer’s primary goals for automation was to increase their overall plant efficiency and increase their battery cell production numbers. The old COS process they targeted for automation required nine or ten employees to operate, and they were looking to decrease that number. BBI also recognized that their employees could be more useful in other areas of the manufacturing plant.

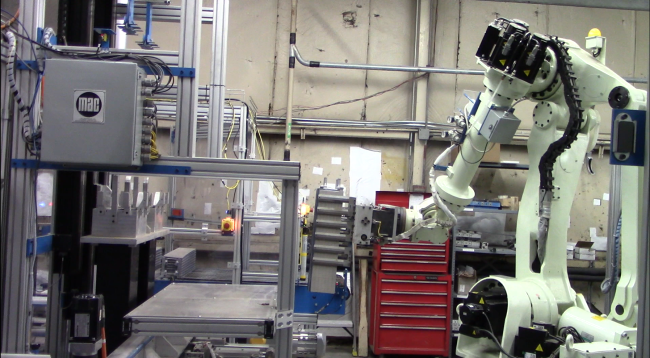

Picture: Kawasaki Robotics

The Kawasaki Solution

• One Robot moves product through entire six station COS process

• Number of operators needed to man this process decreased from seven to five

Almost immediately, Battery Builders saw the advantages of their newly installed Kawasaki robot reflected in the quality of their end product. “We have seen a visible change in the product quality. It’s not only the robot that’s precise in its movements, it’s all of the equipment around it, too. Everything is automated together, and the combination makes for a more accurate product.” – Assistant Manager, BBI

The number of labourers needed to man this process has gone down from seven to five. The robot steps in after the battery plates have been manually slid onto the conveyor to align the plates and ensure they are even and flush. During this new process, operators no longer have to lift the plates from the ground – they move of the plates laterally onto a conveyor which is a more ergonomically friendly move.

From here, the robot picks up the plates and runs them over a large bristle brush to remove any lingering debris from the end connectors, called lugs. Next, the robot runs the product through a flux process. The lugs are then dipped into tin and dipped again into molten lead. Last comes the case out process, where the robot places the battery plates into their plastic casing. Although Kawasaki’s ZX300S robots are capable of carrying payloads of up to 300 kg, they combine a long reach arm with a minimal amount of dead space for a wide work envelope. They also have a high repeatability of ±0.3 mm, making them ideal for applications that require precision and heavy lifting. When combined, these features created the perfect solution for BBI’s setup, which required the robot to be able to reach multiple machines at varying heights.

Kawasaki’s newer large payload robots, the B and CX series, have even higher repeatability, ranging from +-0.06 t0 +-0.08 mm. Both series have a hollow arm structure, which allows for internal dressing of the robot. This feature simplifies installation by reducing the amount of time needed for manufacturing line builds and digital engineering and minimizes the risk of interference with other robots or peripheral equipment.

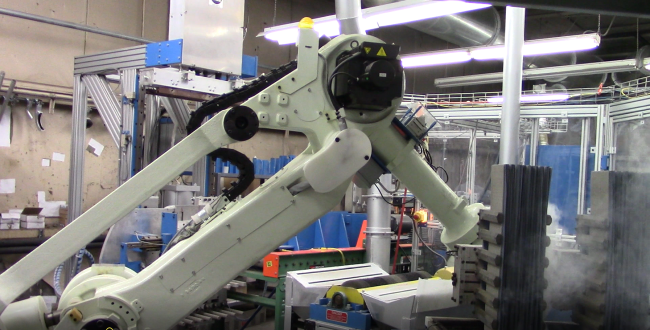

Picture: Kawasaki Robotics

The Results

• One large payload robot covers six-station COS process

• Risk of employee exposure to airborne lead dust decreased

• Product Quality and consistency increased significantly

• Throughput will increase by 150%

For BBI, working with their new robot has been smooth sailing. “The robotics part of this process was very easy. Installing the robot was no problem at all, it was very simple, and learning to work with it wasn’t too complex,” BBI Assistant Manager said.

BBI chose MAC Engineering because the high quality and performance of MAC’s battery making equipment has made them one of the world’s most popular integrators for this type of application. After supplying more than 4,500 machines in over 80 countries to date, MAC is continually looking to the future to develop new products.

Since replacing their old, breakdown-prone COS machine, BBI has seen a better, more consistent product quality using fewer man hours, and created a significantly safer work environment. The employees who used to operate their old machine are now working in the battery assembly department – allowing BBI to put more man hours toward the final stages of battery assembly and ultimately improving the overall quality of their batteries. Once all of the integration is complete, they will be able to increase production from 400 to 1,000 battery cells per day – more than double the output they saw prior to automation.