2 minute read • published in partnership with ERIKS

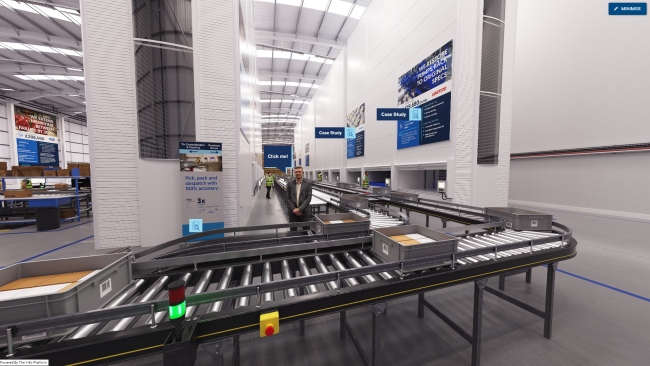

ERIKS launches virtual tour of £22m fulfilment centre

ERIKS has launched a virtual reality tour of its £22m FCE (Fulfilment Centre of Expertise), which is now available to view at ERIKS FCE. The virtual tour, provides an immersive look at the FCE, emphasizing the advantages of central stock management in contrast to local stock management, providing insight into optimising logistics and improving efficiency. This state-of-the-art facility revolutionises the supply chain landscape by offering customers unparalleled flexibility, reliability, and efficiency through centralized stocking.

In recent years, manufacturers across the UK and Ireland have faced unprecedented supply chain challenges forcing many businesses to reassess their supply chain strategies, with a noticeable shift from ‘Just In Time’ to ‘Just In Case’ approaches. However, ERIKS’ new virtual tour of the FCE demonstrates centralized stocking offers a more effective solution, eliminating inefficiencies and limitations of traditional local stock models.

ERIKS has launched a virtual reality tour of its £22m FCE (Fulfilment Centre of Expertise) / Picture: ERIKS

A key advantage of the FCE is its precise delivery options with the choice of next-day delivery, including pre-9 AM, pre-10 AM, and pre-12 PM slots. By utilising a courier service, ERIKS guarantee that customers receive their order when they need it. This level of service is not achievable with traditional service centre van deliveries, which are limited by the number of vehicles available and geographical area.

“The belief that local stock availability is essential is largely a myth,” said Sally Hill, of ERIKS UK & Ireland. “Local stocks often represent 1-2% of the inventory we hold at our FCE, which can be clearly seen via the virtual tour. When local stock runs out, companies are left scrambling to find what they need. This disrupts operations, compromises traceability and quality control. In contrast, our centralized model ensures quick access to over 250,000 products, all managed with the highest standards of quality.”

ERIKS’ FCE offers a more effective solution to manufacturers, eliminating inefficiencies and limitations of traditional local stock models / Picture: ERIKS

The centralized stocking model at the FCE allows ERIKS’ staff to focus on supporting customers with less time spent managing stock and complex logistics. With more time to solve problems, offer expert advice, and delivering product and supply chain training, customers get the parts they need along with the insights to keep their operations running smoothly.

The virtual tour of the FCE demonstrates the scale and efficiency of centralized stocking with the flexibility of modern logistics. With the ability to dispatch 50,000 items an hour and provide next-day delivery on a quarter of a million products, ERIKS is setting a new standard for responsiveness and reliability in the industry.