5 minute read - 24 Nov, 2025

Exclusive: Inside Ideal Heating’s digital transformation journey at Hull factory

There is a huge amount written about artificial intelligence in manufacturing and why companies should prioritise AI projects, but very few examples of the true journey manufacturers take as they implement new technology in their factories.

With a heritage dating back almost 120 years, manufacturer Ideal Heating has kept millions of British homes and business premises warm for decades. Now, Ideal is embracing technological transformation to drive product development and innovation.

From automation and AI, to cloud-based solutions, Ideal’s Production Director John Cook shares the company’s remarkable digital progress.

Taking real-time data to the shopfloor

When I started at the company, a little over four years ago, I was blessed with having a wealth of data on production and processes.

As many as 1 in 3 people in the UK benefit from our heating products each day. That gives you an idea of how much manufacturing data we have at our fingertips!

With a lake of industrial data to help drive our decisions and focused improvement, we faced two questions – how do we apply it in a real-time environment, and who should have access to that level of insight?

For many manufacturers, access to that level of performance data is reserved for senior managers and leaders. We decided to flip the top-down narrative on its head, equipping our entire production teams with the data and insights that underpin our operations.

Bringing together people, plant and process

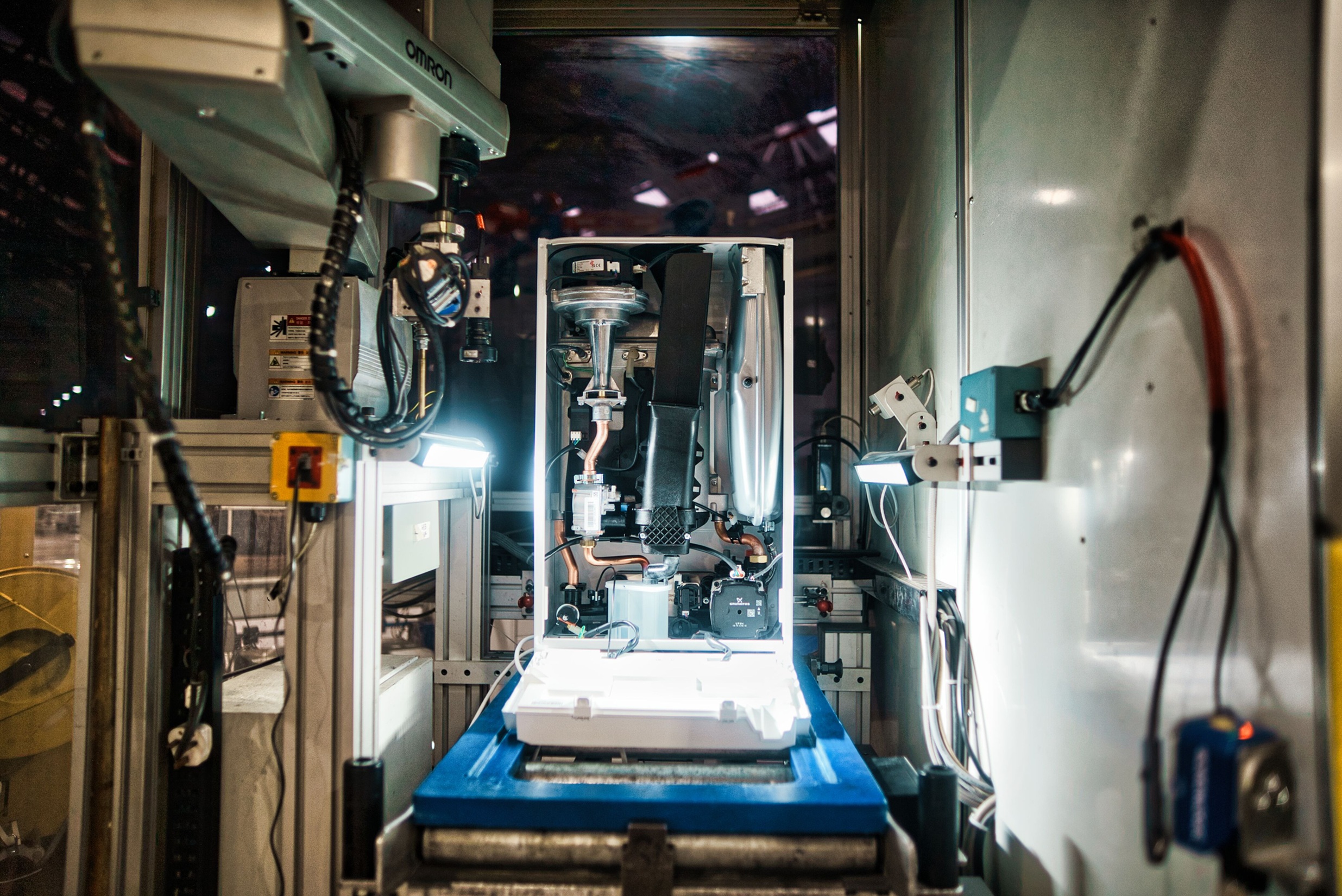

Our transformation began with a strategic approach to digitisation. We implemented advanced vision systems with high-definition cameras, six-axis robots, and cloud-based data analysis that allows us to anticipate challenges before they arise.

Every single member of our manufacturing team can now monitor and track performance, in real-time, across a series of key metrics.

It brings together our people, our machines and our increasingly powerful technology platforms. Putting that right at the point of our manufacturing activity was a massive unlocker of productivity and supporter of quality control.

The results we have seen from this leap forward have been transformational. Take our boiler production operation, for instance. We now use intelligent systems that conduct over 210 quality checks in just 200 seconds.

A six-axis robot with high-resolution cameras compares each boiler against a library of “perfect” images. If something is even slightly off – be it a misaligned wire or a potential structural issue – the system doesn’t just flag the problem. It precisely identifies the exact location, allowing for immediate correction.

Our changeover time between different boiler variants has been drastically reduced, all supported by cloud-based, AI-driven systems.

By handling complex data analysis and repetitive quality checks, the AI systems free our team to focus on innovation, problem-solving and improvement.

Agility is key

Our application of digitisation in production gives everyone instant visibility into performance metrics. That can be anything from production targets and outputs, to quality control and the robustness of our operations.

As a team, we can see which lines are running smoothly, where any bottlenecks may be occurring, and quickly identify defects and issues that may arise.

It means issues can be detected and corrected immediately, reducing downtime and helping us hit our production targets more consistently.

Our portal also tells us how machinery is performing, and can often highlight potential problems before they arise and impact production. It allows for more proactive scheduling of maintenance, and ensures a smoother production flow.

Agility is a word I find myself using regularly, and that’s because it really is key. If we can make informed, data-driven decisions more quickly, we can respond to our customers more reliably at a shopfloor and become more resilient to our increasingly difficult to predict market forces.

AI has given us a wonderful tool in our arsenal

Our production methods may have changed dramatically over the decades, but one thing which remains the same is putting customers at the heart of our decision-making.

We’re looking closely at how artificial intelligence can enhance our customers’ experience, both in the product installation and the daily user experience.

Through AI, we can make the route to market a lot simpler. Take a heat pump, for example. We can now assess the suitability of a home for a heat pump much more quickly, and identify any preparatory work which needs to be carried out to make sure it runs as efficiently as possible.

Heat pumps are more sensitive than boilers, with more external factors impacting their performance and efficiency. By simplifying that learning process for the customer, we can support the electrification of our industry.

From a user perspective, AI embedded in our remote diagnostic software can identify potential faults and issues in products, before the customer is even aware of them. It means we can be proactive in contacting a customer about a possible issue, and send an engineer out to rectify it, before it impacts their experience.

We’ve got a wonderful tool in our arsenal now in AI. We’re still learning every day how best to adopt and utilise it. The opportunities feel limitless.

Invest in AI, or lose out

The reality is that there are companies in every sector adopting AI and using it to great effect. Companies which don’t invest time and resources into AI will lose out.

At Ideal Heating, AI is helping us recruit new people who want to work for a forward-thinking, digital manufacturer, as well as retaining our talent.

The variety of roles in manufacturing is far greater now than ever before, and there’s so much scope for personal development and progression.

Product engineering is the fastest-growing career path in the UK right now, and advanced technologies are at the heart of that. Young people are excited by AI, software and technology. All of those are commonplace in manufacturing. It’s about changing perceptions and showcasing the breadth of careers on offer.