6 minute read • published in partnership with ITI Group

Insight: Lights-out manufacturing – from sci-fi fantasy to today’s smart move

For years, the idea of a lights-out factory – running 24/7 with minimal human oversight – sounded more science fiction than business strategy. But that’s no longer true. It’s accessible, scalable and already delivering real competitive advantage.

Companies that adopt advanced automation – including lights-out manufacturing – can boost productivity and throughput by up to 30%, according to McKinsey. Yet many still see lights-out as out of reach – something reserved for blue-chip giants or brand-new facilities. The reality is it’s a flexible, proven approach that delivers results, regardless of your size. To help manufacturers separate fact from fiction and define their own path to lights-out, Nik Tankard from ITI Group, shares his straightforward, step-by-step approach.

What is Lights-Out Manufacturing?

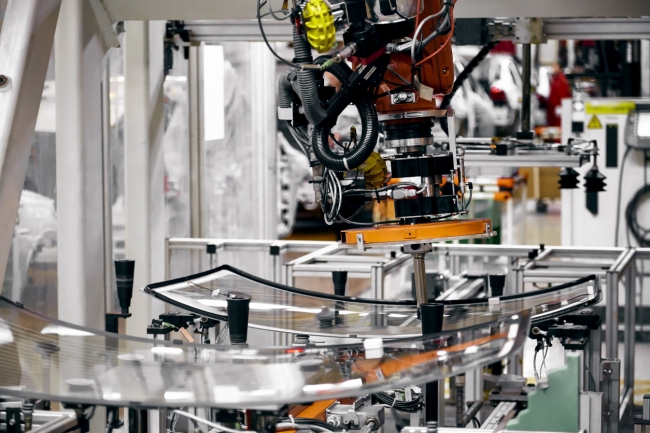

At its core, lights-out refers to a manufacturing facility that operates autonomously without human intervention, enabled by industrial automation, robotics and digital systems. Other names include dark factories or autonomous production, but the idea is the same: machines handle everything from materials handling and production to inspection and even some decision-making.

Why Now?

Four converging factors make lights-out manufacturing more relevant – and more urgent – than ever:

1 – Mature, proven technologies like robotics, cloud computing and vision systems

2 – Ongoing labour challenges from an ageing workforce to rising employment costs and skills gaps

3 – Relentless market demands for speed, quality, traceability and cost-competitiveness

4 – Environmental and regulatory targets pushing for energy-efficient, low-waste and lower-emission operations

Lights-out refers to a manufacturing facility that operates autonomously without human intervention, enabled by industrial automation, robotics and digital systems / Picture: Getty/iStock

Debunking Lights-Out Myths

Several persistent myths hold manufacturers back from even considering lights-out as a strategic direction.

“It’s too expensive.”

That used to be true but today’s modular automation, cloud-based platforms and AI-as-a-service models mean businesses can implement incrementally. Costs have dropped, while ROI has improved.

“It only works for high-volume, low-mix production.”

Not anymore. Modern automation is far more flexible, with machine learning and adaptive systems capable of supporting high-mix, low-volume environments.

“Our operations are too complex.”

Complexity is exactly why technologies like digital twins and advanced analytics exist – to simplify oversight, orchestrate decisions and turn complexity into control.

The Tech Stack Behind It

Lights-out manufacturing is powered by technologies that many factories already use. If you’ve got live machine data, some automation or a connected ERP/MES system, you’re further along the journey than you might think.

1 – Industrial Internet of Things (IIoT)

Live machine data and remote connectivity are now the norm. SCADA and RFID networks link previously isolated machines to create a centralised site-wide – or even enterprise-wide – view. Historical data isn’t locked away anymore; it’s compared with real-time metrics to uncover trends, predict issues and improve decision-making.

2 – Physical Automation

Repetitive, manual tasks like welding, pick-and-place and packing are now reliably handled by robots. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) transport materials where needed, while machine vision systems guide operations and catch defects before they become problems. The result is safer, faster, more consistent production.

3 – Digital Twins

Digital replicas of machines, processes or entire plants enable real-time optimisation – from anywhere. Layer in live data and augmented reality (AR), and technicians no longer need to be on site to solve problems, they can guide interventions from a control room or other site entirely. It’s how a technician in Scotland can diagnose an issue in Cornwall without leaving their desk. Faster diagnostics. Fewer surprises. Smarter problem-solving.

4 – MES and ERP Integration

This is where lights-out starts to scale. When your ERP, MES, SCADA and PLCs talk to each other, instructions flow seamlessly from customer order to finished product – no manual handoffs, no missed steps. Add EDI (Electronic Data Interchange) into the mix and you get responsive, data-driven supply chains that run with minimal friction across businesses and borders.

5 – AI and Advanced Analytics

From yield optimisation and energy efficiency to predictive maintenance and inventory planning, AI is already at work on the factory floor. Manufacturers are using it to flag anomalies, adjust batch parameters on the fly and sharpen demand forecasts. More and more have realised AI is a powerful tool for reducing waste, cutting downtime and boosting performance.

6 – Edge and Cloud Computing

Cloud-based systems provide scalable, secure, global access from anywhere, while edge computing handles local processing in real time. Together, they support decentralised teams, remote collaboration and agile decision-making – all critical to lights-out success.

Lights-out manufacturing isn’t just for blue-chip giants anymore. It’s accessible, scalable, and delivers real competitive advantage to manufacturers of all sizes / Picture: Getty/iStock

The Journey to Lights-Out in Four Stages

This doesn’t happen overnight. Most manufacturers evolve through four strategic steps.

Stage 1: Connected Operations

The foundation is data visibility. That means collecting raw data from machines, cleaning it, contextualising it and making it actionable. This is where MES, historians and dashboards come into play.

Stage 2: Semi-Autonomous Cells

Think “islands of automation.” Robot palletisers, automated assembly lines or AGVs operating with some human input. This is often where manufacturers see their first big ROI.

Stage 3: Integrated Automation

Now comes orchestration. ERP feeds production plans into MES, which synchronises machines, resources and workflows. With AI optimising output in real time, the factory starts to think for itself.

Stage 4: Full Lights-Out Operations

Facilities that run 24/7 with remote monitoring and minimal human oversight. You may not need this level of autonomy today but with the right foundation, you can scale towards it on your terms.

Don’t Jump. Strategise

Unless you’re building a brand-new facility, this is an incremental journey. That’s why the most successful manufacturers take a strategic, phased approach.

Let’s be clear, lights-out doesn’t mean “people out.” It means moving people to higher-value roles like overseeing systems, interpreting data and driving continuous improvement. In our view, the future is human + machine, not human vs machine.

Start by evaluating your digital strategy. Are your investments aligned with where you want to be in five years? If not, pause. Reassess. Technology decisions made in isolation can become expensive dead ends.

Work with partners who understand the full stack – from ERP to edge – and who can align the right tech for your business goals. Choose platforms that can evolve as you do.

And most importantly, start small, but move fast. Prove the business case. Capture value early. Reinvest gains. Keep momentum.

Lights-out doesn’t mean people out – it means moving people to higher-value roles like overseeing systems, interpreting data and driving continuous improvement / Picture: Getty/iStock

The Payoff

The benefits are real and measurable:

• Higher throughput without more headcount

• Improved quality, precision and consistency

• Reduced downtime, waste and energy use

• Modular and adaptive operations

• Lower emissions and better compliance

• Greater resilience to labour and supply shocks

Examples like FANUC’s autonomous factory in Japan – where robots build robots – and Philip’s lights-out razor plant in the Netherlands show what’s possible. But you don’t need to rip and replace. If you’re gathering insights, experimenting with AI or running pilots, you’ve already started. The next step is to scale what works, connect your systems and move towards intelligent, autonomous production.

You can’t control labour shortages, rising costs or mounting competition, but you can take control of your factory’s future. Lights-out is how you build the resilience and agility to face whatever comes next.

The technology is ready. The value is proven. The pioneers are scaling. So, the real question is: what’s stopping you from starting your journey to lights-out?

Digitising your manufacturing processes can seem complex and disruptive – but it doesn’t have to be. ITI Group helps manufacturer define a practical, achievable roadmap to lights-out manufacturing. With its Digital Readiness Assessment, you’ll gain upfront justification you need to drive investment in digital initiatives. Don’t delay digital – the right time is right now.

For lights-out manufacturing success download the Digital Readiness Assessment brochure here.