8 minute read • published in partnership with PP Control & Automation

Insight: Now or Never – the green revolution is a UK manufacturing opportunity for the ages

According to Tony Hague, CEO of PP Control and Automation (PP C&A), if the UK continues to outsource its green technology production overseas, it risks squandering a once-in-a-generation opportunity. Welcome to the race towards a low-carbon future, where a host of clean and green technology sectors are evolving and vying for the unprecedented opportunities that are emerging.

The opportunities I speak of are especially relevant for the United Kingdom, which stands at the threshold of a transformative era. However, we need to embrace it and act now to avoid squandering the chance to achieve a richer economic playing field that we all benefit from. It is a chance, ultimately, to reclaim global relevance, spurred on by the convergence of ambitious net-zero targets, rising public and governmental support, and a burgeoning green technology ecosystem.

There is a caveat. To truly capitalise on this potential, the UK must prioritise manufacturing green innovations onshore. If we fail to retain the production of our green technology domestically, we risk losing not just economic benefits but the leadership role we seek in the global green transition.

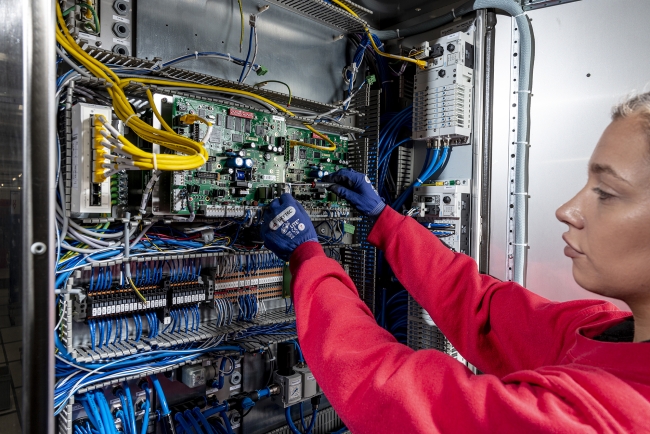

Picture: PP Control & Automation

Clean energy: a UK manufacturing renaissance?

The clean energy sector – encompassing wind, solar, hydrogen, electric vehicles (EVs), and battery storage – is undergoing explosive growth. Ambitious commitments to achieving net-zero emissions by 2050 triggered a surge in renewables, energy efficiency, and climate technologies, including offshore wind – a jewel in the crown of our energy production.

Britain is now one of the world’s leading offshore wind producers. The government’s Energy White Paper (2020) outlined how these sectors could play a central role in decarbonising the UK economy.

There are a couple of side notes at this point.

1 – How healthy is the investment landscape around clean, green, and climate-tech?

2 – Who is making this stuff?

Starting with point 1, the emergence of AI has resulted in shifts across the investment landscape – venture funding for AI has zoomed ahead of climate-tech (BloombergNEF).

In the first half of 2024, climate tech funding dropped by 16% compared to the same period in 2023, whilst AI startups saw a 60% rise in funding. The escalating costs of AI development, which can exceed $1 billion by 2027 for training large models, may be diverting investments from climate tech, especially for early-stage companies struggling to bridge the ‘valley of death’ and secure Series B rounds.

This slowdown comes after a funding boom in 2021-2022, with many investors now waiting for returns before reinvesting. Globally, climate tech funding fell from $44 billion in 2023 to $22 billion in 2024, with the US leading in investments, particularly in clean power and energy storage startups.

As AI soaks up money and investor attention, there’s an underlying feeling that this is but a ‘bump in the road’ for climate-tech investment and not the end, as an enormous amount of capital is needed for climate finance right now, not to mention a healthy collaborative ecosystem to help in scaling up. Make no mistake, AI may be the poster boy right now, but climate-tech and green technologies will bounce back.

Picture: PP Control & Automation

At PP C&A, we’re making a concerted effort to lend a hand in this area through collaborative networks such as PP Plus, CESPA (Clean Energy Systems Partner Alliance), and PPXJ Agritech. More on those later.

On to point 2. While ideas and innovations in green technology have been flourishing on British soil, much of the production has been outsourced abroad, particularly to countries like China and Germany. This is a trend that needs to be reversed if the UK is to maximise the economic potential of its green innovations. It is not enough to simply design groundbreaking technologies domestically; we must manufacture them here and ensure that any economic wealth created stays here.

Onshore, on time, on the growth trajectory

The argument for onshoring clean energy manufacturing and green tech is compelling. First, by producing these technologies in the UK, the country can boost its domestic economy, creating thousands of high-skilled jobs in the process.

Research by Make UK, a high-profile body representing manufacturers, suggests that every industrial job supports up to four additional jobs in the wider economy, contributing significantly to local communities. A 2021 study by Oxford Economics further found that UK manufacturing contributes £192 billion to the economy annually and supports 2.7 million jobs, demonstrating its significance to national prosperity.

In the clean energy sector specifically, the potential for job creation is substantial. For example, the UK’s offshore wind sector alone could generate up to 60,000 direct jobs by 2030, according to the Offshore Wind Industry Council. Add to that the manufacturing roles in battery production, electric vehicles, solar panel assembly, and hydrogen technologies, and it becomes clear that onshore production of clean technologies could act as a catalyst for an employment boom and economic rejuvenation across the country.

Furthermore, manufacturing in the UK ensures the nation retains full control over its supply chains. Recent global disruptions, caused by the COVID-19 pandemic and geopolitical tensions, have underscored the importance of having resilient, local supply. By keeping production at home, domestic companies can mitigate the risks of external disruptions and secure a stable supply of green technologies, which will be vital in achieving net-zero targets on time.

Picture: PP Control & Automation

Intellectual Property and the UK’s innovation leadership

The UK is home to world-class research institutions, a thriving start-up ecosystem, and is increasingly becoming a hub for green innovation. British universities and private companies have pioneered advancements in renewable energy technologies, energy storage, and clean transportation solutions. However, without domestic manufacturing, we risk losing the strategic advantage of being an innovation leader.

Outsourcing production overseas often leads to the export of intellectual property (IP), reducing the long-term benefits of innovation. When UK-born ideas are manufactured overseas, foreign competitors can replicate or reverse-engineer those innovations. This diminishes our competitive edge and undermines our potential to capitalise fully on homegrown ideas.

By manufacturing domestically, the UK can safeguard its intellectual property and ensure that the returns from innovation flow back into our economy.

Onshore manufacturing of green technologies is an economic imperative, but it also aligns with broader environmental goals. To meet its 2050 net-zero targets, the UK will need to drastically reduce emissions across all sectors. Importing green technologies from overseas often arrive with a significant carbon footprint due to shipping and transportation.

Production onshore also supports a circular economy, where resources are used efficiently, waste is minimised, and products are designed for longevity and recyclability. The UK government’s Green Industrial Revolution agenda aims to foster this kind of sustainability-driven economic model. By keeping production local, the UK can embed ‘greener ways of doing things’ into every step of the manufacturing process, from design to end-of-life disposal, furthering its environmental leadership on the global stage.

A missed opportunity we cannot afford

The window to establish a leading role in the global clean and green-tech economy is finite, and countries like Germany, China, and the United States are aggressively positioning themselves to capitalise on it. Failure to act now would not only see the UK fall behind in the race to lead the revolution but would also result in significant economic and environmental costs.

There is a growing public and political consensus around the importance of supporting domestic industries. The British public increasingly favours goods made in the UK, with a 2020 YouGov poll showing that 67% of people believe the government should prioritise supporting domestic businesses. This suggests there is both the political will and public support for policies that promote onshore manufacturing in green technology sectors.

It is one thing to talk the talk on green technologies, and hopefully my passion on this subject is evident, but how am I, and my business acting on it? Well actually, in quite a few ways! The secret here is collaboration.

Better together

We’re no strangers to collaboration at PP C&A, having been a founding member of the Manufacturing Assembly Network (MAN) in 2006, when UK manufacturing was suffering from the collapse of major manufacturers, including MG Rover, Peugeot’s Ryton Plant and Agco.

It was impeded by a lack of Government support and faced with increasing commercial pressures from low-cost rivals in Eastern Europe, the Far East and sub-continent. In short, industry was lacking ambition and confidence.

Founding members of the group had a common interest in tackling these notions and believed the answers lay within a collaborative approach. The group still carries this belief today, and 18 years on, it continues to fly the flag for UK manufacturing, and in recent years, turning its attention to encouraging the next generation of engineers through its rapidly expanding Design & Make Challenge.

Picture: PP Control & Automation

During the pandemic, we set up the #UKMfgUnite platform, attracting over 300 UK manufacturers to help overcome supply chain disruptions and champion the reshoring effort. Today, we have a similar approach through several collaborations that aim to capture this window of opportunity in clean and green technologies.

The first of those collaborations is PP Plus, a carefully curated collective with over 20 organisations across UK manufacturing, academia, and professional services. It is acting as a single source for green tech start-ups to bridge the commercial valley of death and scale faster.

Born from close collaboration with other members of the PP Plus ecosystem is a new partnership that has become the bridge between cutting-edge agricultural innovation and bringing the technology to market. PPXJ Agritech is helping innovators with everything from access to academic researchers and leaders, to the design and engineering capabilities needed to realise agricultural innovations.

Our most recent endeavour is CESPA (Clean Energy Systems Partner Alliance), a pioneering collaboration between six industry leading companies. The partnership is harnessing innovation in clean energy systems through an alliance of complimentary design & engineering capabilities, and hardware & software solutions, to drive efficiency and environmental stewardship.

We’re actively building a blueprint for better collaboration across the spectrum of green technologies, which, at its heart, is driven by the imperative of keeping production onshore.

Picture: PP Control & Automation

We must retain our economic value

The emerging green technology sectors offer a historic opportunity for UK manufacturers to lead the global clean energy transition, to solve rapid environmental changes and escalating food demands, and to benefit from sustainability and a circular economy.

In short, by manufacturing green technologies domestically, the UK can create jobs, strengthen its economy, secure resilient supply chains, and meet its climate goals.

Importantly, keeping production onshore ensures that the UK retains the economic value of its innovations and remains at the forefront of global efforts to combat critical issues such as climate change. This is a window of opportunity that the UK cannot afford to miss. By investing in onshore manufacturing now, the UK can build a greener, more prosperous future for generations to come.