4 min read • published in partnership with PP C&A

Insight: The capacity trap and how in-house thinking is slowing OEM growth

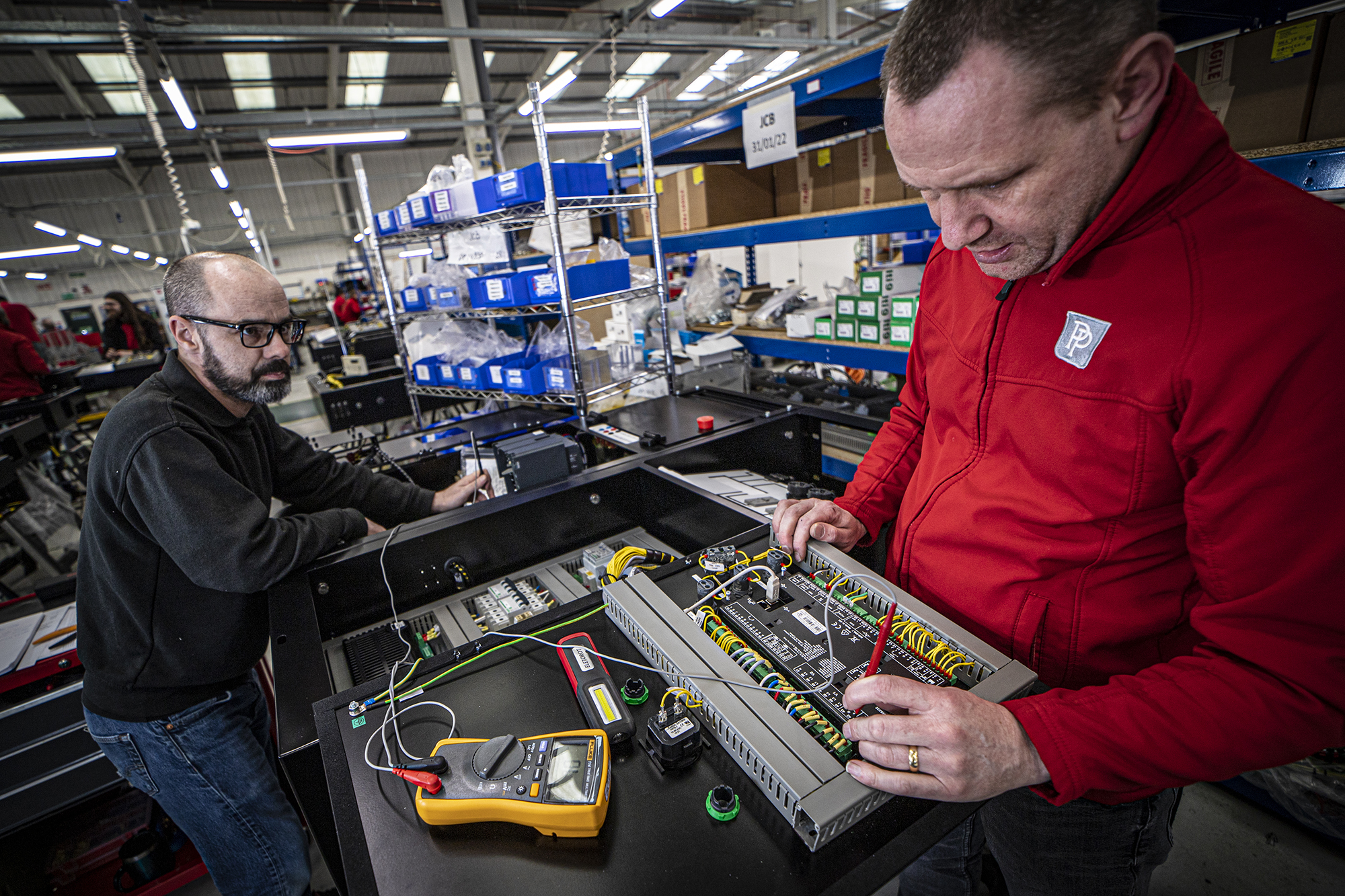

In the first of three editorials on the hidden cost of in-house manufacturing, PP Control and Automation’s Richard Spears explores why the model – once a symbol of strength – is now a strategic constraint, and how outsourcing is helping forward-thinking OEMs break free.

For many machine builders and Original Equipment Manufacturers (OEMs), the decision to keep production in-house is rooted in a sense of control – control over quality, lead times, cost, and, increasingly, confidentiality.

But for all its perceived security, this traditional model often becomes the very thing that holds a business back. What starts as operational discipline quietly turns into a constraint. And by the time it’s recognised, it’s already limiting growth.

The signs are easy to ignore at first. A stretched production schedule here, a delayed shipment there, extra overtime, extended lead times and a growing backlog are all telltale signs. They are often explained away as part of the normal rhythm of manufacturing, but behind the scenes, capacity is maxed out and the business is stuck running harder just to stay at the same pace.

This is what is now being commonly referred to as ‘the capacity trap’. A point where internal production can no longer support the ambitions of the business, yet nobody wants to admit it. Demand is growing, whilst the ability to fulfil it is shrinking. The shopfloor is full; the labour pool is tight and adding more of either feels unfeasible. Teams continue to firefight the symptoms, as the underlying issue persists. Put simply, the business has outgrown its in-house capability.

This isn’t failure – it’s friction. The natural byproduct of success. But when that friction is allowed to persist, it becomes more than an operational headache. It begins to impact commercial confidence. Sales teams hesitate to chase larger orders. Engineers are pulled away from design to assist in production. New product introductions are delayed. And the business starts choosing what it can do, rather than what it should do.

Some manufacturers respond by turning to patchwork solutions – squeezing more from the same floor space, cross-training staff, or pushing for short-term overtime. However, these are pressure valves, not pathways to growth. They might relieve the strain for a while, but they don’t solve the underlying constraint. At best, they mask it. At worst, they burn out the people holding it all together.

The real turning point comes when a business tries to scale internationally – that’s when the limits of in-house operations truly show. A surge in demand from overseas customers isn’t something you can navigate with duct tape and goodwill. It requires flexibility, consistency, and the ability to manufacture at volume, without compromising quality. And if your internal capacity is already at breaking point, global opportunity quickly becomes global risk.

So, what’s the alternative?

Outsourcing isn’t about giving up control – it’s about regaining it in the areas that matter most. By partnering with a specialist manufacturing provider, OEMs can offload repeatable, resource-intensive tasks whilst retaining full ownership of engineering, IP, and customer relationships. It allows businesses to create space. Not just physical space on the shopfloor, but strategic space to focus on what moves the needle. Things like innovation, customer experience, and new market development.

A good outsourcing partner doesn’t just build parts, assemblies and machines – they build continuity. They bring structured processes, embedded quality systems, and scalable capacity that flexes with your business. They allow you to clear backlogs, shorten lead times, and deliver more consistently, without investing in extra headcount or floor space. And in doing so, they unlock the opportunity that’s been waiting behind the bottlenecks.

Critically, this isn’t about replacing internal teams. In fact, it’s about enabling them. When production pressure lifts, engineering can return to solving problems instead of managing workloads. Operations can plan proactively rather than reactively. Leadership can look forward, instead of down. That’s what growth-ready manufacturing looks like, and it rarely happens smoothly when everything is kept in-house.

The capacity trap isn’t an operational issue. It’s a strategic one and it requires a strategic response. Businesses that continue to treat in-house capability as sacred will eventually be outpaced by those willing to build smarter, not just harder.

If your team is constantly stretched, if your backlog is growing, if you’re turning down opportunities because you ‘don’t have the bandwidth’, then you may not have a production problem. More than likely, you may have a mindset problem.

Because in modern manufacturing, control isn’t about doing it all yourself. It’s about knowing what to do in-house, what to outsource, and having the confidence to act before capacity becomes crisis.

Richard Spears is Marketing Manager at PP Control & Automation, one of the UK’s leading outsourcing manufacturing specialists.

Every year, the West Midlands-based business works with more than 20 of the world’s leading machinery builders, innovators and technology specialists, covering everything from energy and infrastructure, food and beverage, to machine tools, industrial automation and agritech.