4 min read • published in partnership with PP C&A

Insight: The triple threat constraining in-house production

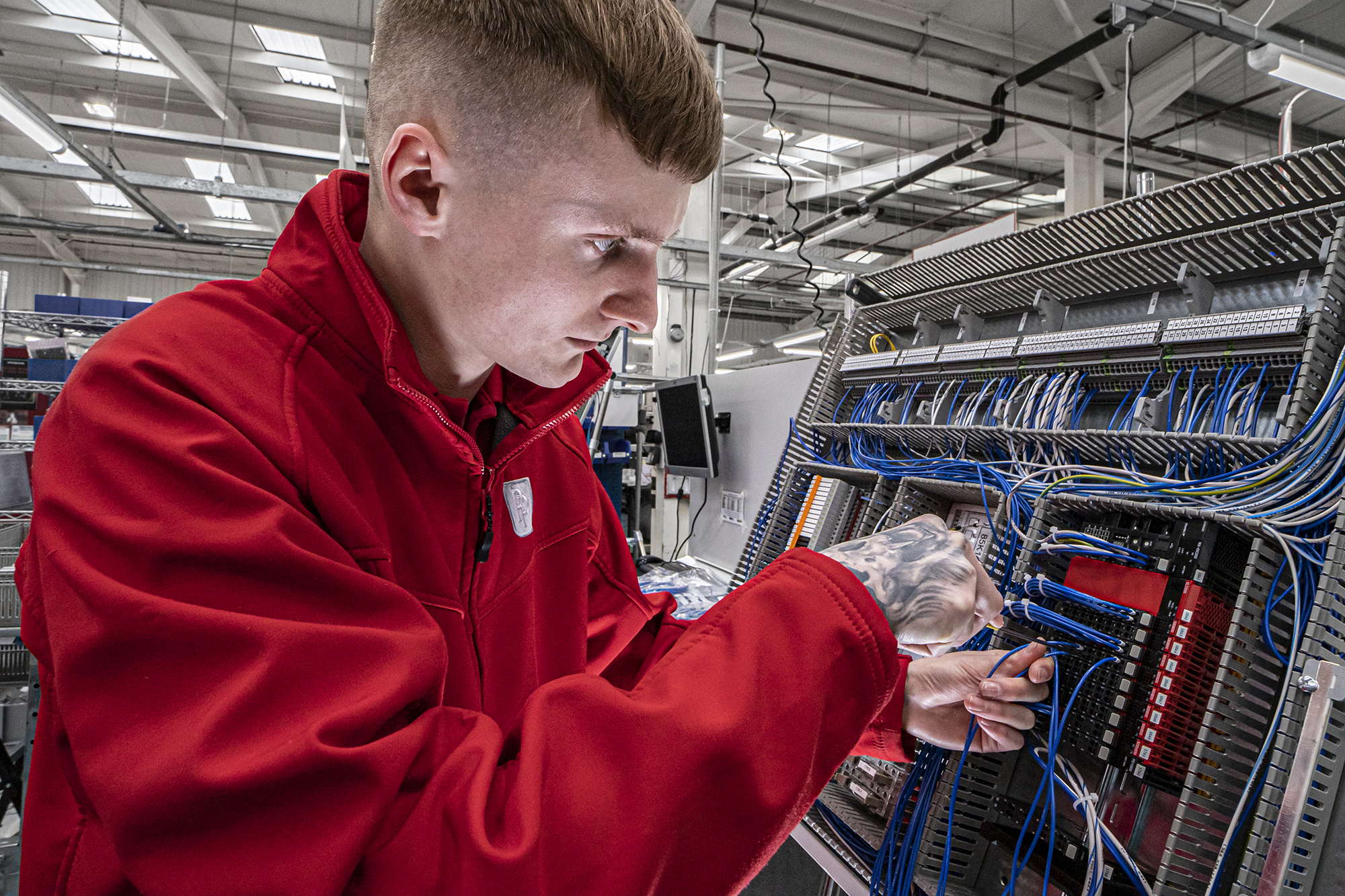

The pressure on OEMs isn’t coming from a single source, it’s coming from all sides. Products are more complex, quality expectations are rising, and skilled labour is harder to find than ever.

Together, they’re creating a bottleneck that in-house teams are increasingly unable to break through. In this final edition of the hidden cost of ‘in-house manufacturing’, PP Control & Automation’s Richard Spears explores how these three forces are coming together to create a challenging puzzle and why outsourcing could be the best way of solving it.

Modern machine building demands more than ever before – more integration, more compliance, more intelligence, more precision. Product complexity continues to rise, yet many OEMs are relying on production models built for a much simpler time. The result? A widening gap between what’s expected and what in-house teams are actually able to deliver.

At first, the cracks are small. A few minor reworks, a slipped test procedure, maybe even a component fitted incorrectly under pressure. But these issues aren’t anomalies. These are the first signals and real signs that internal production capacity, capability, or skill is no longer aligned with the sophistication of the product. And, if left unaddressed, those cracks will grow into delays, customer complaints, and costly reputational damage.

Quality is rarely compromised by choice. More often, it’s a consequence of overstretched teams working under increasing pressure. Skilled technicians are expected to absorb more complexity, faster. Engineers are pulled into production support to troubleshoot builds that aren’t fully productionised. Test procedures are compressed to meet shipping deadlines. There’s little time for continuous improvement. Instead, we settle for just enough time to get the job out of the door.

Compounding this is the industry-wide skills shortage. The workforce is ageing, recruitment pipelines are thinning and, as much as we want them to, apprenticeships can’t plug the gap quickly enough. For many OEMs, it’s no longer a matter of finding the right skills but holding onto them long enough to get the job done. That fragility means even modest fluctuations in headcount or workload can cause serious disruption to production.

At the same time, product designs are becoming more ambitious. Integrated systems, digital controls, safety features, diagnostics, connectivity. Each and every new function adds complexity to the build. And that complexity requires specialist knowledge, controlled environments, and tightly managed processes. When these don’t exist or simply aren’t given enough time to mature, manufacturing quality becomes reactive instead of embedded.

And then comes the biggest bottleneck of all: turning a prototype into something that can be built at scale. Many OEMs find themselves stuck between concept and manufacture, where great designs falter under the weight of in-house constraints. Engineering teams are caught in an endless loop of fixes. Builds are inconsistent and testing becomes guesswork. Sadly, the product, which should have pushed the business forward, becomes another source of stress.

Outsourcing offers a really important release valve, and this doesn’t just have to be for pressure. It can also be a release valve for risk. The right manufacturing partner brings in immediate capability: qualified teams, advanced integration experience, clean and ESD assembly areas, UL and compliance expertise, structured test environments, and scalable output. Strategic partners build and they industrialise. They take what’s been designed and make sure it can be built, repeatedly, reliably, profitably and to spec.

For OEMs facing a widening skills gap, this kind of external expertise is protection. It ensures continuity when internal capacity falters. It protects quality standards when production gets busy. And it frees up internal engineering to focus on product development, not repeat builds.

Importantly, outsourcing is a deliberate decision to build resilience into your operation. A choice to focus on what you do best – whether that’s designing machines, engineering solutions, or serving customers – whilst your partner handles the complexity of production with the right systems in place.

Manufacturers who make this shift early avoid quality risks and they go on to accelerate growth. On a positive note, they also shorten time-to-market, they enhance customer satisfaction, and they build products with the confidence that every unit will meet the standard, no matter how complex design becomes.

The longer OEMs try to manage this complexity alone, the greater the risk becomes. Talent will continue to be scarce. Products will continue to evolve. And internal teams will continue to bear the weight – until something gives.

If quality is slipping, if production can’t keep pace with design, or if the skills just aren’t there to meet demand, it’s not a production issue. It’s a strategic one. And it’s time to rethink what the price of ‘in-house’ is really costing you.

Missed the previous articles? Catch up with part one and part two here.

Richard Spears is Marketing Manager at PP Control & Automation, one of the UK’s leading outsourcing manufacturing specialists.

Every year, the West Midlands-based business works with more than 20 of the world’s leading machinery builders, innovators and technology specialists, covering everything from energy and infrastructure, food and beverage, to machine tools, industrial automation and agritech.