9 minute read • published in partnership with Lloyds

Modern by design – How AW Hainsworth unlocked 60% growth by redefining its identity, culture and capability

AW Hainsworth’s journey from heritage mill to high-growth, purpose-led manufacturer offers a blueprint for strategic reinvention. Revenue has grown from £15m to £24m in just four years. Now, the eighth-generation business is targeting £30m by 2030 – and helping redefine UK textiles in the process.

AW Hainsworth has woven wool in Yorkshire for over two centuries, building its reputation by clothing troops at Trafalgar, Waterloo and in both World Wars. Today, its woollen fabrics are trusted by fashion designers, Hollywood costume departments, global airlines and royalty.

For most of its modern life, the company leaned on its military and ceremonial past. But over the past four years, Hainsworth has undergone a profound shift. Under new leadership, the team has overhauled operations, clarified its direction and grown revenue from £15m to £24m. Now, the focus is on reaching £30m, guided by WIN2030 – a meticulously prepared five-year strategy that aligns culture, operations, technology and sustainability to further modernise the mill and secure its long-term future.

Rebranding to reflect modern relevance

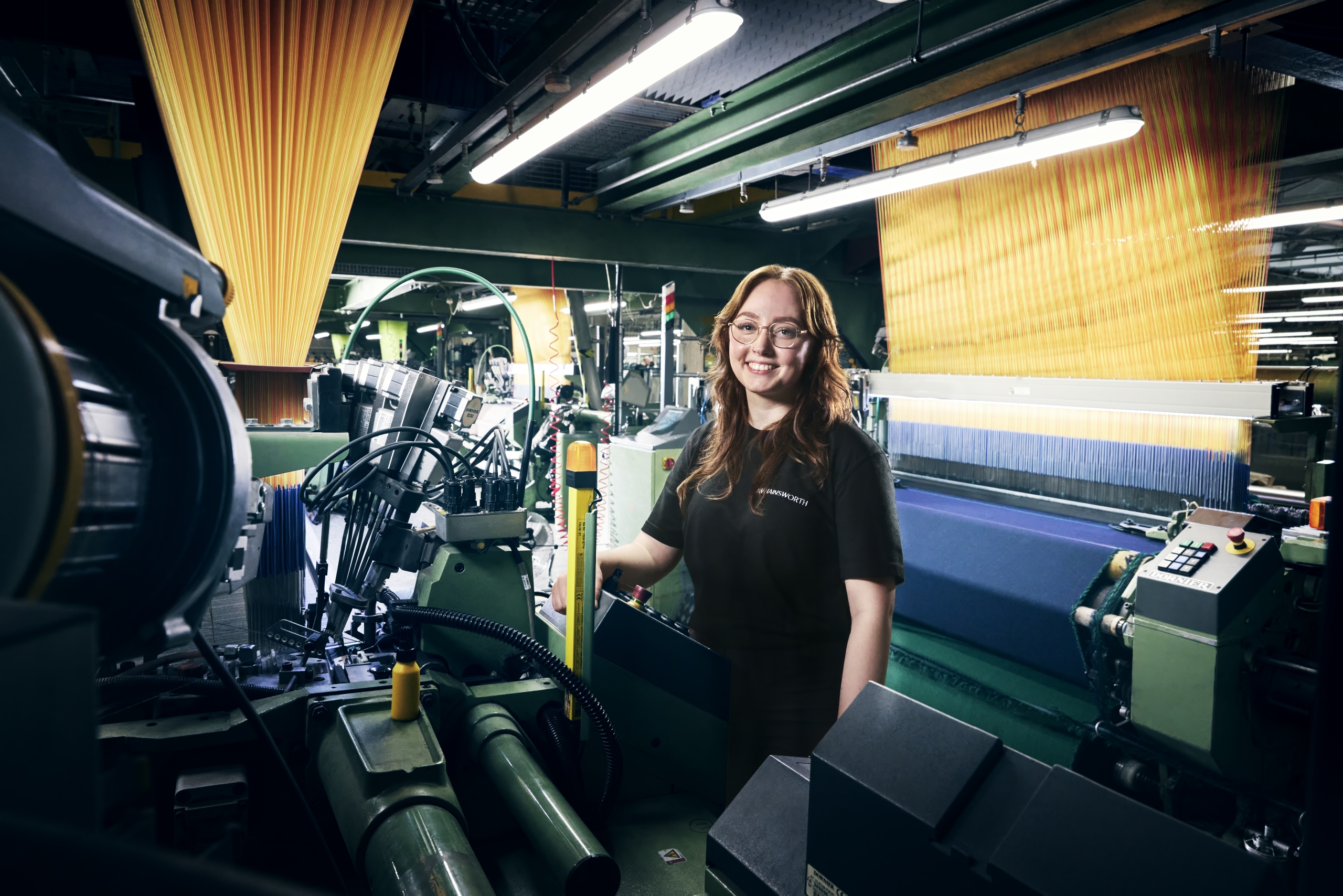

The first step in its transformation was rethinking how the company presented itself to the world. A narrative centred around tradition and craftsmanship no longer served its ambitions. If Hainsworth wanted to attract new talent and stay relevant, it needed to start telling a different story.

“We weren’t talking about the fact we make fabric for costume designers at Netflix and Disney. Or that Victoria Beckham uses our cloth in her winter collection. Or that nearly every firefighter is protected by our flame-resistant fabrics,” says Amanda McLaren, Managing Director. “That’s the kind of real-world relevance that gets young people’s attention, and changes their perception of a career in textiles.”

Determined to define a new path, Amanda and her team have driven a total cultural reset, helping clarify the company’s direction, language and values. The result is a company that’s proud of its past but focused on relevance, innovation and future skills.

Building a culture fit for the future

“We knew if we wanted to futureproof the business, it had to start with our people.” At the heart of Hainsworth’s transformation is a tangible cultural shift. When Amanda took charge, the company had an ageing workforce (20% were aged 64 or over) and health-related absence was high. While the depth of knowledge and expertise was impressive, it was clear a new generation was missing.

This sparked a twofold strategy: to become an employer of choice and to develop meaningful support systems that reflect the realities of employee’s lives. Seeing that mental and occupational health had previously been overlooked, Hainsworth now invests £20,000 annually in tailored wellbeing initiatives designed to help staff thrive at work. These include private onsite counselling, a menopause support group, wellbeing workshops and employee-led physical fitness clubs.

The impact has been significant. Mental health-related absence now accounts for just 0.131% of cases (compared to the 40% industry average), labour turnover sits at just 2% and 25% of employees are aged 35 or under. Sixteen employees (around 10%) are trained in mental health first aid. And recognising that those offering support often need it too, a peer support group has been introduced.

Above all else, consistency is key, Amanda says. “You can’t play at this. You can’t offer support one year and pull it the next because the budget is tight. That’s not how you build trust. You need to partner with charities and counsellors who stick around. That’s when your team starts to believe in you and the business they’re part of.”

Equally important has been bridging the generational gap. The business has created structures to facilitate knowledge transfer between long-serving staff and new hires, without positioning one as a threat to the other.

“Attracting younger talent goes beyond just recruitment. You have to create an environment for them to learn, contribute and challenge established norms,” Amanda says “At the same time, you have to respect and retain time-honed skills. Long-serving staff must feel safe and respected in sharing their experiences, not threatened by it.”

A unique competitive edge

A cornerstone of the company’s transformation is its state-of-the-art laboratory – a £250,000 investment in the future of textile innovation. The UKAS-accredited testing facility plays a central role in both product development and commercial growth.

Equipped for rigorous physical and chemical testing, from tensile strength to colour fastness, the lab ensures that fabrics meet the most demanding specifications, particularly for high-stakes sectors like protective wear. Where no standard tests exist, the company develops in-house methods to simulate extreme conditions, reinforcing its reputation for innovation and reliability.

Crucially, the facility anchors a broader move to refresh and expand Hainsworth’s product portfolio, driven by the hiring of a new commercial director and three international sales managers.

By reconnecting with the market and identifying unmet customer needs, Hainsworth is translating deep technical experience into a pipeline of commercially viable, high-value products. The lab underpins this process, fast-tracking the development and validation of new materials while emphasising quality, consistency and profitability.

The lab has also become a powerful tool for reshaping perceptions. For customers, the visible commitment to innovation signals a clean, high-tech, quality-driven approach. For new hires, students and teachers, the lab challenges outdated assumptions – offering tangible proof that a career in textiles can be technical, dynamic and rewarding.

Investing in operational self-reliance

The lab reflects a wider commitment to operational agility. As one of the last vertical mills in Britain, Hainsworth can take a product from raw fibre to finished cloth entirely on-site. That level of self-sufficiency and control has deepened with the creation of an engineering centre – designed and built by the team.

Equipped with machining, welding, woodworking and 3D printing capabilities, the centre enables Hainsworth to maintain and improve its complex manufacturing operation in-house. Parts that once took weeks to source can be prototyped overnight and fitted by morning, dramatically reducing disruption and enhancing responsiveness.

The maintenance team has been complemented by mechanical, electrical and electronic specialists, creating a multi-disciplinary unit encouraged to not just fix faults, but prevent them. This proactive mindset has reshaped the company’s maintenance strategy and investment planning, fuelling a broader culture of continuous improvement.

This ethos extends to digital transformation. A cross-functional digitalisation committee, led by young talent and with support from Made Smarter, has compiled a ranked list of 22 projects focused on automation, workflow optimisation and improved decision-making.

With funding and support from Made Smarter, a government initiative to support and enable manufacturers to adopt digital technologies, Hainsworth has mapped out its digital journey and begun making changes. Replacing its outdated ERP system with a more robust, future-ready solution is first in line.

Scaling capacity to support growth

With growth now driven by strategic sales and product expansion, operational capacity is the next bottleneck. “We were running at 60% efficiency when I arrived,” Amanda says. “The capacity is there but unlocking it requires significant targeted investment.”

That investment – totalling £10.5m – underpins the WIN2030 strategy – which began with a frank look at Hainsworth’s commercial ambitions versus operational realities. Every sector, product line and revenue target was converted into meterage and mapped against machine time, headcount and throughput. The result is a transparent, granular plan that drives smart decisions and avoids surprises.

The first upgrades are already delivering results, including replacing three 50-year-old looms with two high-speed, high-precision machines. Though fewer in number, the new looms offer 30% more output and leave space for further expansion.

While progress to date has been largely self-funded, the next stage will require external backing. Hainsworth’s long-term relationship with Lloyds will be instrumental to support continued investment in digitalisation, automation, upskilling and specialist equipment.

“Lloyds has taken the time to understand WIN2030 not just as a strategy but as a long-term journey we’re on, and they’ve responded with genuine partnership,” Amanda says. “Over the past four years, they’ve been with us every step of the way, from helping us manage working capital to structuring finance around large, front-loaded investments. They’ve provided exactly the kind of support a business like ours needs.

“I can’t speak highly enough of the team. Lindsay Crooks, our Relationship Director, has been a consistent source of guidance and support. She’s built a deep understanding of where we’re going and what it’s going to take to get us there.”

Lindsay Crooks, Relationship Director at Lloyds, said: “Lloyds is delighted to be able to support Amanda’s WIN 2030 strategy and provide finance to expand its international footprint, seek out new markets, and invest in new machinery, whilst supporting AW Hainsworth in retaining its heritage.”

Embedding sustainability into strategy

“Sustainability isn’t a tick-box exercise for us.” From maintaining Zero Waste to Landfill to introducing energy-efficient machinery, Hainsworth continues to make substantial progress in reducing its carbon footprint – not only by improving its processes and facilities, but by triggering a company-wide shift towards a sustainable mindset.

Publishing an annual sustainability report has been central to that journey, providing tangible evidence of the improvements made and the road ahead. Now in its fourth year, the report details targets and reductions, ongoing projects and future initiatives.

“We’re proud of our results so far but we’re even prouder of the mindset change,” Amanda says. “Sustainability now sits at the heart of our company values and the business. Our latest report shows clear progress, and I’m confident it will set Hainsworth apart as a true investor in sustainability strategy.”

The company has formalised its commitment by partnering with Planet Mark to establish an externally verified carbon baseline and define a route to Net Zero. Its biggest step has been investing in two new roles – a Head of Sustainability & Engineering, and a Senior Process & Sustainability Engineer – to lead monitoring, measuring and understanding the company’s true impact.

Other recent investments range from simple changes – like introducing ‘RackSacks’ throughout the mill for dry mixed recycling and installing real-time energy monitoring equipment – to retrofitting inverters to optimise fan speeds used for drying and stretching cloth and installing a heat recovery system to improve process efficiency.

In the past 12 months, Hainsworth has cut electricity and water usage by more than 10% and gas by 6%. This year, the company is on track to reduce total carbon emissions by 5%, with a new borehole water treatment plant due online in 2026 to improve water management and operational efficiency even further.

Environmental efforts are matched by rigorous ethical standards. Hainsworth undergoes regular audits to maintain accreditations, and ensure traceability for the Responsible Wool Standard. The company has also adopted a local-first sourcing model, drawing materials and services from West Yorkshire wherever possible – from loom parts in Bradford to woven labels in Guiseley, and even catering from less than a mile up the road.

“Our customers want confidence not just in our products but in how we do business. Our job is to ensure that confidence is well placed,” Amanda says.

A clear path forward

As WIN2030 progresses, Hainsworth recognises that futureproofing the mill means making it more accessible – to talent, to innovation and to the broader industry. The business is looking to commercialise several core capabilities, with plans for the lab to begin offering a premium textile testing service to new and existing customers. The engineering centre, too, could evolve into a subcontract manufacturing facility, expanding Hainsworth’s role as both a supplier and enabler of national capability.

Reinvention is rarely easy, but AW Hainsworth shows it can be done. With a clear strategy, aligned leadership, a culture that blends tradition with ambition, and the support of an engaged financial partner, it’s proving that the future of textiles can be sustainable, competitive and proudly British.