4 minute read - 18th May 2023

See Inside: Oyster Yachts’ UK-based factory sites

Oyster Yachts is celebrating its 50th anniversary in 2023. Designed and built across four build centres in Norfolk and Hampshire, we take a look inside and explore some of the facts & figures behind these sites.

Picture: Chris Ison / Oyster Yachts

Oyster continues to invest in new production facilities, techniques, and technology, always striving to make their yachts better and more sustainable. With a forward order book extending over two years, Oyster is implementing more efficient production processes across its four build centres in Wroxham & Ashmanhaugh, Norfolk and Southampton and the newly acquired state-of-the-art production facility at Hythe, Hampshire.

Picture: Chris Ison / Oyster Yachts

A freshly moulded 565 hull and deck, awaiting final quality assurance sign-off by Lloyd Register prior to fitting deck to hull.

Picture: Chris Ison / Oyster Yachts

From on deck, right down to the keel, all Oyster hulls boast uncompromising strength of construction certified by Lloyd’s Register or DNV, featuring a combination of stringers and frames for extreme durability and safety.

Picture: Chris Ison / Oyster Yachts

A white NPG resin gel coat is standard for Oyster, which has excellent UV resistance and waterproofing qualities. Applied to its optimum thickness – not too thin that it compromises waterproofing, but also not too thick that would make the surface brittle. Oyster’s approach is about the quality of a beautiful, moulded surface that weathers the elements and time.

Picture: Chris Ison / Oyster Yachts

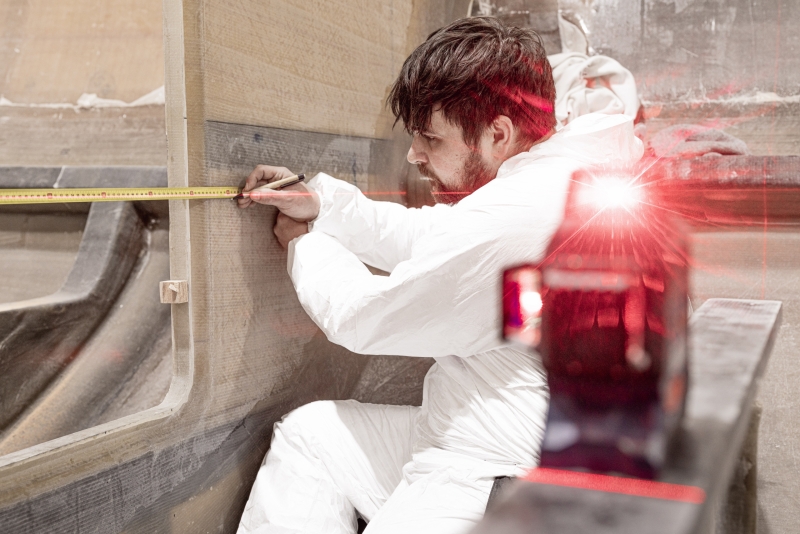

Rigorous attention to detail and quality assurance checks are applied even before full-blown fit-out commences and are continued throughout the manufacturing process.

Picture: Chris Ison / Oyster Yachts

Meticulous preparation of the cockpit internal moulding liner, ready-to-accept headlining soft furnishings and downlight fittings.

Picture: Chris Ison / Oyster Yachts

Oyster’s outstanding quality is a result of the finest British master craftspeople and meticulous attention to detail. Hand-selected veneers are grain and colour-matched throughout.

Picture: Chris Ison / Oyster Yachts

The standard of craftsmanship is exceptional, from the hand-built cabinetry to the intuitively placed handholds, – an unrivalled detail. Each Oyster is unique and built to reflect the personality and taste of individual owners.

Picture: Chris Ison / Oyster Yachts

Cabling behind the scenes is both named and numbered to make testing, troubleshooting, and maintenance simple. Exterior cables have tinned cores for anti-corrosion and uncompromised connection. Extensive use of waterproof connectors, both above and below decks significantly extends the lifespan of electrical connections and components.

Picture: Chris Ison / Oyster Yachts

Oyster’s design approach combines expert naval architecture, time-served craftspeople, modern materials, and the latest proven technology. Every detail has been carefully considered and space is maximised for comfort in the large volumes down below.

Picture: Chris Ison / Oyster Yachts

Oyster’s DNA is rooted in over 20 million bluewater sailing miles and over 100 circumnavigations of the globe. This relentless pursuit of perfection allows constant evolution and refinement that makes Oyster one of the most reliable yacht brands.

Oyster is a British boatbuilder, with a deep and enduring heritage built over the past 50 years. Each yacht is hand-built by life-long, passionate, and proud boatbuilders who bring these special yachts to life.

Picture: Chris Ison / Oyster Yachts

Oyster is a British boatbuilder, with a deep and enduring heritage built over the past 50 years. Each yacht is hand-built by life-long, passionate, and proud boatbuilders who bring these special yachts to life.

Picture: Chris Ison / Oyster Yachts

Oyster is committed to growing a sustainable and environmentally responsible business that nurtures the passion of the Oyster family. It continues to invest in the future by introducing new technologies and techniques across all sites and functions, which work in harmony with the time-honoured craftspeople and staff that are at the heart of every one of its yachts.

Picture: Chris Ison / Oyster Yachts

With a growing team of over 600 employees and an award-winning apprenticeship scheme established, Oyster continues to go from strength to strength. Tradition is an important part of what it does and is preserving these skills by investing heavily in training young craftspeople so that future generations can continue to experience the joy of Oyster.

Picture: Chris Ison / Oyster Yachts

There has been a strong focus on improving the quality of every aspect of these already impressive yachts. Hull and deck mouldings are now certified by Lloyds’s Register. The latest nautical and domestic technology is incorporated into every design and build. And every element, from door hinges to winches is often over-specified for performance, strength, and longevity. The levels of finish and luxury are unparalleled.

Picture: Chris Ison / Oyster Yachts

Over 100 Oysters have completed a circumnavigation of the globe. This is the dream voyage for many sailors and why Oyster yachts are uniquely suited to every time one of their exquisite yachts leaves its factory.

We would like to ‘See Inside’ your factory and share some insight about the investment, growth and future plans you have – if you wish to be featured, please get in touch on hello@zenoot.com