6 minute read • published in partnership with ITI Group

Smart Manufacturing: Six steps to beat the odds and achieve your goals

Digital technologies can dramatically improve manufacturing operations but many investments fall short. Nik Tankard from ITI Group shares six essential steps to ensure your digital manufacturing strategy is a success.

Manufacturing businesses are investing more in digital technologies than ever, reaping benefits like increased efficiency, improved quality and reduced carbon emissions. In fact, almost three-quarters of industrial directors believe digital technology will drive operational improvements in 2024 and beyond.*

Yet, the adoption of digital technologies isn’t always straightforward. Many initiatives stumble due to lack of clarity, poor planning or inadequate execution. The statistics make for sobering reading:

• Less than 30% of digital projects meet their goals (McKinsey)

• Just 10% of companies have realised a tech-enabled business model (Bains & Company)

• Only 30% of digital initiatives result in sustainable change (Boston Consulting Group)

Picture: Getty/iStock

Nik Tankard, senior digital transformation manager at ITI Group, has seen these challenges firsthand. With nearly two decades in manufacturing, he’s led numerous continuous improvement projects and helped companies unlock value from technology.

Through these experiences, he’s observed a clear pattern: effective companies align digital technologies with their broader business goals, while those fixated solely on technology often struggle, overwhelmed by data without a clear purpose.

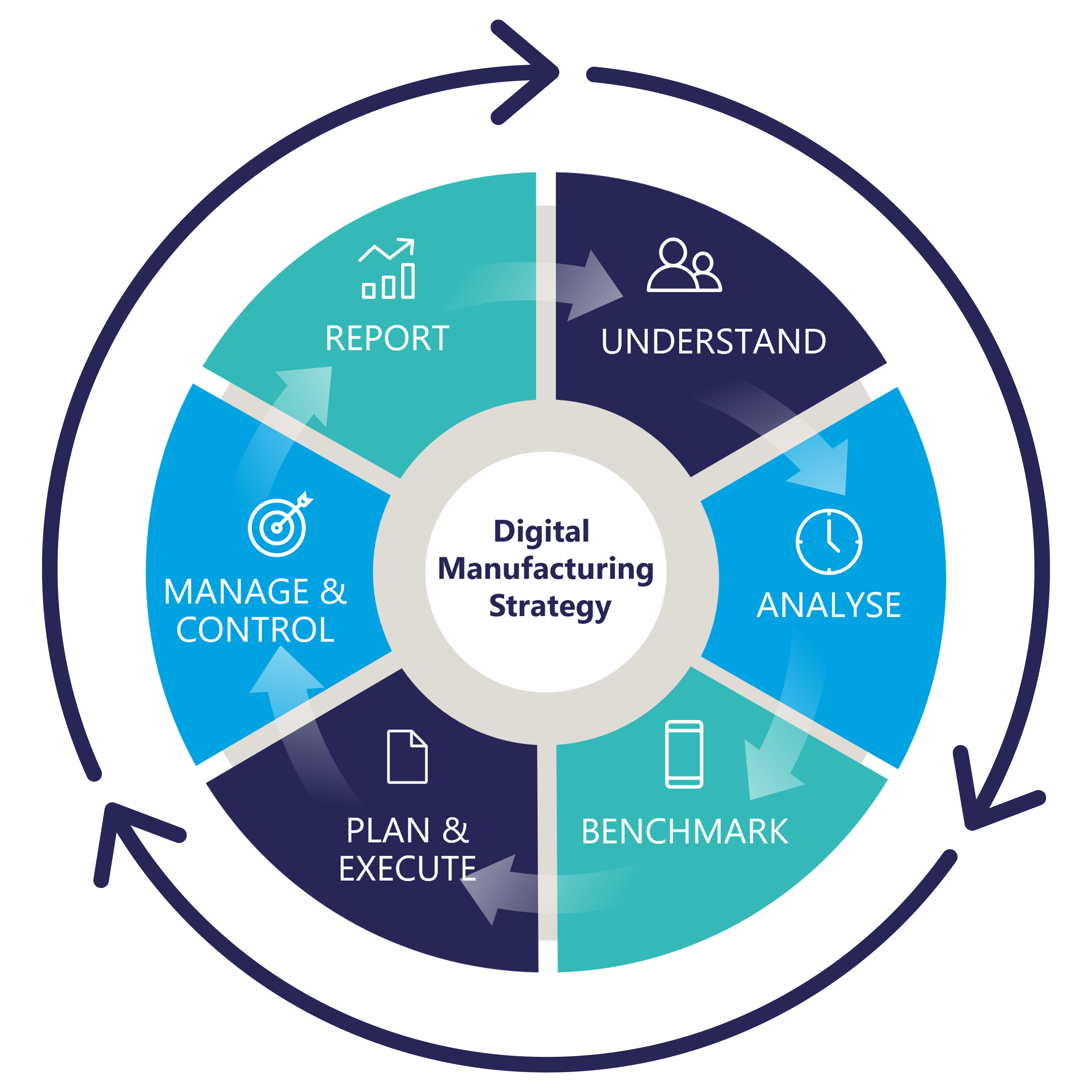

To help manufacturers avoid these pitfalls and achieve their business goals, Nik shares his six-step framework for a successful digital manufacturing strategy:

1 – Understand

Start by aligning digital initiatives with your company’s strategic direction. Don’t risk having to remove a solution after 12 months because the business direction wasn’t understood upfront.

Be visionary. Consider where you want to take your company. What can you do now versus what you want to do in the future? Conduct a gap analysis to understand where your company is and where you want it to be in the short and long term.

Engage key stakeholders early to ensure alignment on objectives and expectations. A fundamental reason why digital projects fail is poor adoption. Involving end-users from the start increases the likelihood of delivering change successfully.

2 – Analyse

Next, conduct a thorough analysis of your processes and workflows to determine how digital technology can add value. Remember, software is just a tool; real benefits come from improving processes. This step presents an excellent opportunity to enhance efficiency and effectiveness across your operation, even if you decide not to adopt digital technology immediately.

Use Value Stream Mapping and Lean principles to identify inefficiencies and areas for improvement. Additionally, use a Data Inventory Framework to assess what data is already available, how it is being used and what data you actually need.

These insights will help build a robust, compelling business case, quantifying both tangible costs (such as upfront software expenses) and intangible costs (like staff training, IT infrastructure upgrades and potential disruption to operations). Your business case should also define clear success criteria, such as generating X amount of additional revenue or improving OEE by X percent.

3 – Benchmark

With a clear understanding of how digital technology can benefit your operation, you now need to decide between out-of-the-box (OOTB) and bespoke solutions.

OOTB software typically offers more features and functions versus custom solutions. However, studies show that around 40% of software functionality never gets used. So, is it really beneficial to invest in a software package that can do more but never will?

OOTB solutions tend to be more stable and easier to maintain but usually require your business to adapt its process to fit the software. In contrast, custom solutions can be tailored to your company’s specific needs and workflows.

Choose a technology partner that aligns with your long-term vision, and evaluate their domain expertise. Any provider can implement a solution but only those with a deep knowledge of your industry can advise on how best to solve your specific challenges.

It’s also important to consider their maintenance and support offerings. Downtime can have severe consequences, especially with business-critical systems. Assess how timely a partner can get you back online, where their service teams are based and whether they offer remote support.

Picture: Getty/iStock

4 – Plan & Execute

There are three common approaches to technology implementation, each with pros and cons.

A pilot allows you to trial the process change in a small area to minimise risk. However, this often extends the project timeline and cost.

A phased implementation allows you to start generating business value incrementally. However, it may involve additional training and costs as the technology evolves.

A big bang approach, where the new process is implemented across the entire site overnight, can be the most cost-effective, but be prepared for higher risk and potential disruption.

Once an approach is chosen, planning for the implementation is essential. The sooner the intended change becomes ‘business as usual,’ the sooner you start realising the benefits.

People are at the heart of every change. Workers will undergo their own change management process but will need to be trained and upskilled to support the implementation. Changes to the wider organisation may also be necessary, such as adjusting roles or responsibilities and policies or procedures.

5 – Manage & Control

Studies show that scaling up is a bigger hurdle than getting started. Success hinges on clear governance, coordination, quality control, progress mapping and stakeholder communication. Failure to manage these aspects can lead to significant issues. Here are a couple of real-world examples I’ve encountered:

Example 1: A manufacturer scaled up their digital solution after a successful implementation at a UK site. Without effective governance, stakeholders at each new site demanded unique features, resulting in a dozen versions of the same solution – some nearly identical.

The company ended up paying for the same solution multiple times over and faced issues when it came to maintenance. A formal change advisory board has since been implemented to regain control and provide oversight.

Example 2: Another company, after boosting productivity by 15% in 18 months with a new MES solution, planned an immediate group-wide rollout. However, they had overlooked the need to standardise business KPIs and terminology. Ensuring consistent terminology and metrics across all sites is crucial before rollout, requiring stakeholder agreement on definitions and measurements.

6 – Report

Tracking and reporting progress is crucial for any digital or capital investment project. Choose KPIs that reveal whether the implementation is on track and allow for ongoing evaluation. Key areas to measure include user adoption, system stability, and whether process changes are delivering the expected benefits.

Continually compare performance against the initial goals and have a way to capture feedback, ensuring any criticism is given and received constructively. Be prepared to evolve and adapt for long-term success, which takes me to an often-forgotten seventh step…

7 – Repeat!

The first step was aligning digital initiatives with your company’s strategic direction. However, business directions can shift at any time. Take Covid-19 as an example, companies had to adapt quickly to changing circumstances. With so many internal and external factors, today’s problems or goals may not be the same next week. Continually reassess and realign your digital strategy to stay in sync with evolving business objectives.

Graphic: ITI Group

No matter where you are on your digital manufacturing journey, it’s never too late to develop a strategy. Investing in upfront planning and clearly defining your requirements is far more cost-effective than fixing errors after implementation.

Start with a clear, focused approach and scale quickly can help you adapt to evolving technology and market conditions. Aligning digital initiatives with your business goals not only addresses today’s challenges but also future-proofs your operations for whatever tomorrow brings.

At ITI Group, our industry-leading experts leverage over 50 years of experience to plan, prepare and deliver projects that drive real success. We turn innovative, intelligent solutions into tangible business value, and our clients keep coming back because we excel at aligning technology with their business goals. You know your operations; we understand the manufacturing industry and the technology. Together, we achieve more.

To learn more about how ITI Group can support your digital roadmap, email enquiries@itigroup.com or call 01274 599955