8 minute read • published in partnership with Lloyds

The secret to success – how Technoset invested in skills, new technology and new opportunities to drive growth

Technoset is proof that the secret to growth is never standing still. Whether investing in cutting-edge technology, seizing new opportunities, developing future talent or reducing environmental impact, this supplier of ultra-high precision parts is always moving forward.

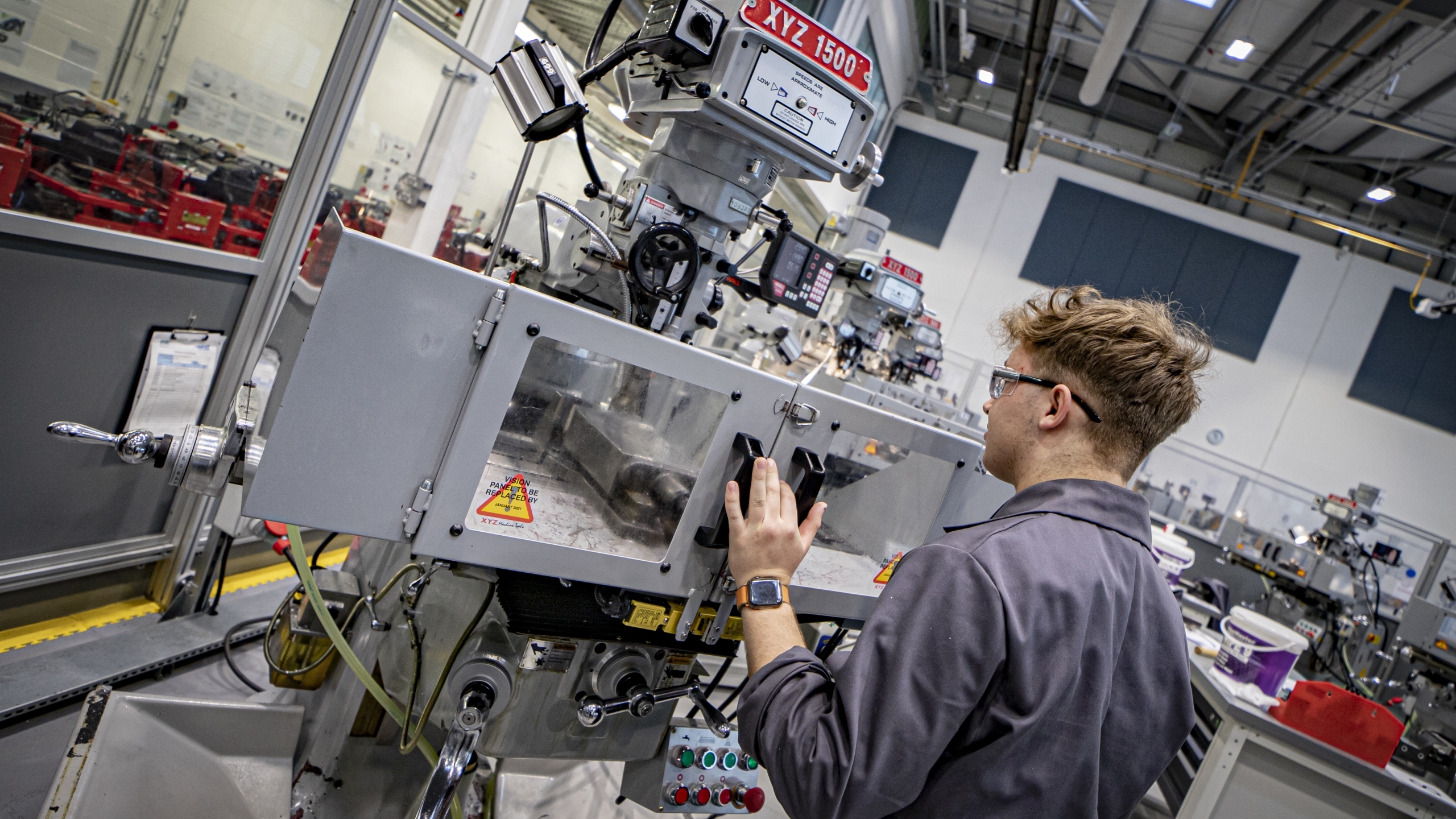

Stepping into Technoset’s high-tech factory in Rugby, you immediately feel the energy of a business that refuses to stand still. For nearly 50 years, this precision engineering powerhouse has quietly redefined what’s possible, delivering turned and milled components to industries where failure isn’t an option.

Aerospace accounted for 70% of Technoset’s order book when the Coronavirus delivered a catastrophic hit to the supply chain, accelerating a transformation that’s been in motion since 2019. What started as a planned evolution became an urgent reinvention – one that would futureproof Technoset and drive growth in entirely new directions.

Investing for the future

“We never stop trying to improve.” That mindset drives Technoset’s approach to investment, and the numbers back it up. In the last 12 months alone, a £650,000 investment drive has enhanced production with two Star SL 10 sliding head lathes to meet rising demand for ultra-precise parts and two Mitutoyo Crysta-Apex Coordinate Measuring Machines (CMM). A factory reorganisation has streamlined material flow and final inspection has been relocated to a new purpose-built area.

Automation is at the heart of this transformation. In a first-of-its-kind integration, a DMG MORI DMU 50 milling machine, paired with an ABB SC3000 FlexLoader, has introduced the latest in 5-axis machining with automated material handling and tool change. The result is improved milling performance, faster output, shorter lead times and more cost-effective production.

Crucially, it enables “lights out” around-the-clock manufacturing, where complex, multi-axis machining is completed with little to no human supervision, “a game-changer” for efficiency and competitiveness, says Adam Land, Managing Director.

These investments, supported by an Asset Finance package from Lloyds, have strengthened Technoset’s presence in aerospace while opening doors to fast-growing emerging markets.

Pushing the boundaries

Markets change. Demand fluctuates. Success belongs to those who adapt. For Technoset, that means applying its expertise to high-growth sectors like telecommunications. The rapid rise in 5G, satellite communications and smart connected devices presents lucrative opportunities for suppliers of high-precision machined components – exactly what Technoset has built a reputation for delivering.

“We can’t afford to be locked into one market,” explains Adam. “That’s why I’m constantly encouraging the team to push boundaries and challenge what’s possible, to adopt new technologies and focus on long-term goals.”

The cultural shift Adam has instigated is paying off. For two years, Technoset has been developing the capability to supply high-performance fibre optic connectors, where tolerances are 100 times thinner than a human hair. These connectors are in high demand, with applications across residential, military and commercial broadcasting.

After identifying a key machine, conducting extensive trials with the original equipment manufacturer (OEM) and demonstrating proof of capability, Technoset has made its next major investment: a £500,000 multitasking DMG Mori NTX 500 mill-turn centre, supported through Asset Finance from Lloyds.

To further enhance productivity and precision, Technoset intends to incorporate a high-accuracy instant measurement system with the NTX 500. This move positions the company to secure high-value contracts not only in telecommunications but other demanding markets like high-performance automotive, medical, hydrogen and renewable energy.

A greener, smarter factory

Regular investments in upgrading machinery, increasing capacity and adding new capabilities are helping Technoset realise its ambition of a sustainable, efficient and digitally connected operation. To that aim, the company has taken significant steps to cut energy consumption, minimise waste and improve the working environment.

316 solar panels have been installed on the factory roof providing up to 139kWp, slashing energy costs and reducing reliance on the national grid. Other factory-wide upgrades, including over-cladding to improve insulation, smart heating controls, LED lighting, a closed-loop component cleaning machine and new compressors, have further optimised energy use and stabilised internal temperatures for better working conditions and production quality.

Under Adam’s leadership, Technoset has also rapidly advanced its use of data and digital tools to increase process flow, track key performance indicators (KPIs) and improve decision-making. With support from the Made Smarter programme, a government initiative to support and enable manufacturers to adopt digital technologies, Technoset is now using carbon fibre composite 3D printing for rapid prototyping, creating durable, high-quality parts that better match final production pieces.

Data-driven quality control

On the data front, a key breakthrough has been the development of Power BI dashboards. Initially introduced by a Coventry University postgraduate on placement, the tool demonstrated immediate value by quickly analysing 12 months of production data. Seeing its potential for trend analysis and continuous improvement, Technoset now has a full suite of dashboards embedded in its intranet, allowing staff to view sales, orders, factory throughput, work-in-progress and overall equipment effectiveness (OEE).

Another key advancement is how Technoset now uses its production control system, PSL Datatrack. An evaluation by Adam revealed that it was a crucial piece of software for the whole business, but wasn’t being used properly. Targeted training for workers has transformed the system into Technoset’s command centre, providing real-time scheduling, process tracking and live production monitoring.

Quality control has also gone digital, with Bluetooth-linked measurement tools replacing paper-based inspection records. Previously, defective parts went unrecorded, with no way to track trends or pinpoint recurring issues. Now, all in-process measurements and defect density are captured and analysed, allowing causes to be addressed at the source – helping to cut scrap at final inspection to just 0.15%.

“Live production data and real-time oversight of operations have been key,” Adam says. “We’re leaner, more responsive and better positioned to serve industries that demand absolute precision, reliability and traceability.”

Building the next generation

As a former apprentice with Warwick Manufacturing Group (WMG), Adam understands the power of skills development. That’s why apprenticeships are central to his strategy for securing Technoset’s future. “Future-proofing and succession planning are essential,” he says. “Some team members have been with us for over 40 years, and while their experience is invaluable, we must plan ahead.”

To ensure the next generation receives the best training, Technoset works with Manufacturing Technology Centre (MTC) Training. Having worked at MTC before joining Technoset, Adam knows firsthand the quality of training and its commitment to strengthening UK manufacturing through advanced skills. “Our apprentices gain exposure to a wide range of advanced manufacturing techniques, while also building problem-solving, communication and adaptability skills, which are key in a modern engineering environment.”

Beyond training, MTC is also helping Technoset find the right candidates for the right role. Recruitment, often a challenge, is streamlined through their pre-screening. Candidates undergo rigorous assessments before reaching Technoset, ensuring only the most capable apprentices join the team. “The support they provide, from receiving our job description through to enrolment, is incredibly useful,” Adam says. “It means we only meet approved candidates who have the right foundation to succeed.”

Once enrolled, apprentices split their time between MTC Training’s state-of-the-art facility and real-world experience at Technoset, ensuring they hit the ground running. This dual model has proven to help apprentices integrate smoothly into the business, ensuring hands-on work reinforces the knowledge and techniques apprentices learn.

Lloyds has partnered with the MTC since 2015 to help manufacturers access skills and expertise. Their partnership funding will continue to the end of 2029, with a £15m sponsorship. In addition to supporting training and recruitment, their partnership funding is also enabling a Salary Support Scheme. This is helping businesses like Technoset to invest in future talent, even in uncertain economic periods. “It’s been a deciding factor in our hiring and has been instrumental in growing our apprenticeship programme,” Adam says.

Stuart Andrews, Relationship Director at Lloyds, added: “Technoset is an example of a business that has invested heavily in apprenticeships with the Manufacturing Technology Centre and is reaping the long-term rewards.”

Developing skills at every level

Since reviving its apprenticeship programme under Adam’s leadership, Technoset has seen real success. Young engineers are now thriving in the business, including Tyler Gillespie, a recent graduate who was named Lloyds SME Apprentice of the Year and is now being supported to complete an Engineering HNC at MTC Training. Technoset’s newest apprentice, Samual Lightfoot, the fourth Technoset apprentice to be trained at the Lloyds sponsored training centre, is nearing the end of his first year, with plans in place to recruit a further two in September.

However, training great engineers is only part of the equation – retention is just as important. Technoset has broken through the ‘glass ceiling’ many small businesses struggle with by fostering continuous development, offering challenging projects and creating a culture that encourages advancement. “We know not every apprentice will stay with us for 40 years,” Adam says, “but by recruiting and developing the best, and giving them strong career opportunities, we’re building a strong position for our future.”

Training doesn’t stop at apprenticeships. Technoset invests in the growth of every team member, with personal development tailored to their roles and career progression. Every employee has a structured training plan and set annual targets for hours of learning. The company also collaborates with local universities and is planning to host another six-to-eight-month graduate placement this year.

Poised for future growth

That Technoset has been able to pivot from aerospace dependency to a diversified, high-growth business is no accident. The leadership team saw change coming and met it head-on, proactively investing in new technologies, new talent and new approaches. And the investments aren’t going to be paused.

“I’ve always focused on what’s coming down the road and how can we be better,” Adam says. “I want our team to share the same opportunities I had – to work with emerging technologies, to improve processes and to drive real change in a meaningful career.”

Technoset’s relationship with Lloyds has been instrumental in accelerating its growth. “Stuart Andrews, our Relationship Director, has been incredibly supportive. He understands our company and the challenges we face, and has been a great advocate,” Adam says. “The investments Lloyds has supported have had a huge impact on our growth, but the business guidance they’ve provided, particularly around sales and exports in our case, has been equally invaluable.”

With a new machine incoming, a greener, smarter factory and a workforce combining time-served experts and fresh talent, the stage is set for Technoset’s next phase of growth. One key target is expanding its global exports. Currently, 7% of Technoset’s output goes to the United States, but the goal is to grow that significantly over the next 24 months, with Lloyds playing a key role in supporting that expansion.

With a strong foundation, a culture of continuous improvement and the right strategic partnerships, Technoset is poised to take on the future and succeed.