7 minute read • published in partnership with Lloyds

Walking with giants – The small firm making a big impact on critical infrastructure projects

Berry & Escott is proving that size is no barrier to supporting the most demanding supply chains thanks to cutting-edge tech, a deep commitment to apprenticeships, and a mindset for solving problems others avoid.

Berry & Escott is a steel fabrication and engineering company supporting tightly regulated sectors, including nuclear and defence. What sets it apart is how it blends time-honed expertise and digital technology with a unique approach to problem-solving.

Based in Bridgwater, Somerset, the business took its current form when Directors Lee Berry and Chris Escott joined forces to expand its capabilities and market reach. With nuclear power undergoing a resurgence, the directors saw an opportunity to become a bigger player in high-growth global supply chains. The business had already worked on Hinkey Point A and B, and when Hinkley Point C began taking shape nearby, the time had come to go further.

The compliance, rigour and technical demands of modern nuclear work brought challenges, but Berry & Escott emerged stronger, sharper and ready for the future. Now, with a proven track record and growing demand for its expertise, the firm is looking beyond Hinkley to play a bigger role in UK and international infrastructure projects.

From painful lessons to profitable growth

One question has defined the firm’s recent development: How to become part of the biggest engineering project in Europe? A major milestone was completing the government-backed Fit For Nuclear (F4N) programme, designed to help manufacturers meet the sector’s exacting quality, safety and reliability standards.

F4N status opened the door to Tier 1 work on Hinkley Point C. But getting there wasn’t without setbacks. Despite having prior experience, the business underestimated the scale of change required.

“We went in thinking we had all the answers,” recalls Scott White, Sales Manager. “But the reality was very different.” The steep learning curve took its toll on the business, and changes had to be made.

The turning point came with targeted support from Lloyds. “We’ve always had a good relationship with Lloyds, but when times were tough, that really came into its own,” Scott says. “They backed us when it counted, and gave us the time and guidance to regain our footing.”

The result is a business now growing with confidence. In 2023, Berry & Escott beat its £4.9m revenue target to hit £5.3m, with a £6.3m order book. Its track record at Hinkley has opened doors for future opportunities at Sizewell C, the new power station under construction in Suffolk, and helped secure approved supplier status with Rolls-Royce, recently selected to lead the UK’s Small Modular Reactor (SMR) programme.

Simon Davidson, Relationship Manager at Lloyds, added: “Having faced a skills challenge in the past, Berry & Escott is an excellent example of an engineering company investing in its apprentices. Having prioritised a substantial apprenticeship programme, alongside cutting-edge technology, it has developed the right strategies to support long-term growth.”

Investing to stay ahead of client demands

Backed by stable, long-term work and rising demand, Berry & Escott is using investment as a competitive lever, boosting its ability to reduce waste, risk and cost at every stage. The business is shifting towards a fully digital-first operating model, one where cutting-edge 3D scanning, virtual modelling and precision machining operate as one seamless, intelligent workflow to guarantee right-first-time production.

Unlike many firms that offer scanning as a bolt-on service, Berry & Escott has put it at the heart of its workflow. It has developed deep expertise in two complementary systems: Creaform, a metrology-grade handheld scanner for small, intricate parts, and FARO SCENE 3D for capturing the shape, size and location of large objects or structures – invaluable when aligning new designs to existing infrastructure.

On a major utilities project, 3D scanning revealed subtle misalignments around large storage tanks – small enough to escape traditional methods, but serious enough to cause installation issues on-site. By designing components directly from real-world scan data, Berry & Escott machined custom offsets that ensured a perfect fit – avoiding costly rework and delays.

“Basic measurements assume the world is perfectly square and true. It’s not,” Scott says. “High-resolution scanning gives us the confidence to say installation will happen on this day, it will take this long and cost this much. Customers know exactly what to expect, and we deliver to it. No surprises for them or us.”

So far, over £360,000 has been invested in scanning and inspection tools. Its latest acquisition – a £35,000 seven-axis FARO Quantum Max ScanArm – enables engineers to verify machined components against digital models in real time, building a live 3D map of the part as checks are performed. “Customers can be with us in the inspection room watching the system prove parts are within tolerance. That’s the level of transparency it brings.”

Next, the business intends to invest in digital twins and immersive virtual environments, enabling engineers and clients to walk through designs pre-build, spotting risks and issues early, and ensuring health and safety is addressed upfront.

Solving the skills gap from the inside out

Off the back of a growing order book, Berry & Escott has doubled its workforce to nearly 60 employees, including 13 apprentices. That apprentice-to-headcount ratio is unusually high but entirely by design.

Recruitment is tough for any SME, but Berry & Escott has found that offering young people purpose, progression and real responsibility makes a powerful difference. Apprentices are quickly integrated into live production, working on components destined for customers rather than the scrap bin. That ownership drives motivation, says Scott; “When they see their work going out the door, it fills them with pride. They come in earlier, study harder and feel part of something.”

It’s a win-win model. By developing talent in-house, Berry & Escott ensures skills match the company’s exacting standards and future direction. “If we want the skills, we have to grow them ourselves.” Apprentices are given a clear path from day one, with several senior leaders – including the current Operations Manager and HR Manager – having started in apprentice or junior roles.

The long-term ambition is to become an accredited training provider, delivering in-house technical education and mapped career routes – from welding and machining to project management, design, compliance and finance. “If we can take someone at 16 and guide them through every step of a rewarding career in industry, that’s a legacy worth building,” Scott says.

That commitment extends beyond its own four walls. Berry & Escott has designed and built training simulators for Cannington College and the National College for Nuclear, including pipework flow loops, cable-routing rigs and full-scale weld test areas. One simulator even sits inside a purpose-built training centre the business designed and constructed itself – a tangible sign of its drive to create regional centres of excellence in engineering training.

This philosophy flows from the top. Both directors are strong advocates of lifelong learning, with one recently completing a 10-week AI bootcamp to better understand how emerging technologies will shape future engineering workflows. It’s part of a broader mindset, says Scott; “Educating young people is critical, but so is educating ourselves. That’s how we stay ahead.”

The art of engineering the impossible

‘Grey Space Engineering’ is how Berry & Escott manages complex project requirements, solving issues the drawings don’t reveal before they become problems on site.

“Think of a sat nav. It constantly assesses changing conditions like road closures or congestion to keep you moving. That’s what we do – adapt in real time to find the best route, even when it doesn’t exist yet.”

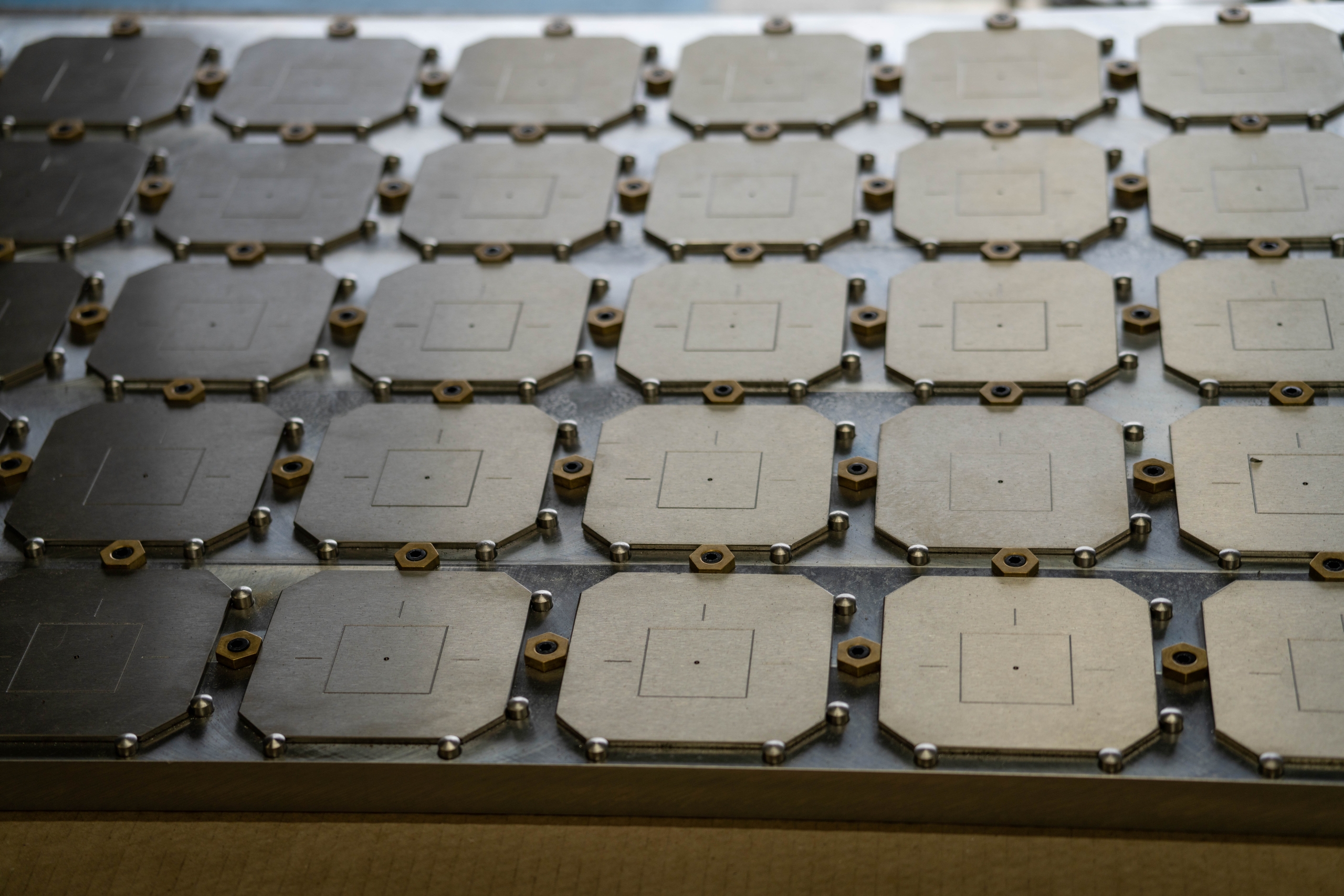

This approach proved critical on Hinkley Point C. Dozens of steel plates had been embedded in concrete foundations to align with the feet of large tanks to follow. But welded metal distorts, no matter how well controlled, creating a misalignment between the tank feet and plates.

Rather than wait for new specifications, Berry & Escott took ownership. The team scanned each interface, digitally matching each tank foot to its corresponding baseplate, and developed bespoke adapters to guarantee perfect alignment. The whole process – design, approval, manufacturing, quality assurance and delivery – was completed in-house, giving the customer complete clarity and confidence.

That level of proactive innovation is now the standard. It’s a powerful differentiator and a core part of how Berry & Escott develops its people, too. Project ownership and creative problem-solving are part of daily workflows, not reserved for specialist roles.

Geared up for what comes next

With 70 nuclear reactors under construction worldwide and 400 more in planning, the opportunity for high-integrity suppliers has never been greater. As a proven partner to the likes of EDF and Rolls-Royce, Berry & Escott has the experience and credibility to seize it.

The business has clearly defined short-term goals: a purpose-built facility, a 90-strong team and £10m+ in annual revenue by 2030. Achieving them depends on securing further nuclear work at home and overseas, converting that momentum into continued expansion across aerospace and defence, and bringing more capability in-house. Growth will be underpinned by continued investment in automation, compliance systems and digital workflows.

But for Scott, growth isn’t about scale alone. It’s also about impact. Applying lessons from Hinkley. Helping Sizewell get off the ground faster. Making sure public money goes further.

“It’s a strange thing, a small business in Somerset working side-by-side with giants. But that’s the story of UK manufacturing. Incredible businesses doing unbelievable things, right across the country. We just need to get better at shouting about it.”

Berry & Escott is leading by example. With hard-won experience, the trust of global brands and a clear vision, it’s ready to take a central role in supply chains that will power the decades ahead.