5 minute read

Conquering the 100% in-line inspection challenge

Dynacraft is a diversified global manufacturer of PACCAR medium- and heavy-duty truck parts sold under the Kenworth, Peterbilt, and DAF nameplates. For more than 40 years, Dynacraft has provided the company’s truck manufacturing divisions and PACCAR parts division with high-quality components, subassemblies, and specialized services.

“One of the requirements going into the new 2017 emission systems, which we are producing currently, was a requirement from our supplier quality group to do a 100-percent inspection of the emissions assemblies,” explains Mario Caudillo, production quality engineer at Dynacraft. “We were performing a standard sampling plan up to that point, so it was quite a challenge to try to go from a sample plan to 100-percent inspection.”

Although Dynacraft runs more than 200 assemblies daily through its production line, one manual measuring arm and a few technicians were sufficient to keep up with sample testing. It took very little introspection, however, for the Dynacraft quality team to determine there was absolutely no way they could do a 100-percent inspection with their existing process. An automated solution would be required to meet the customers’ expectations.

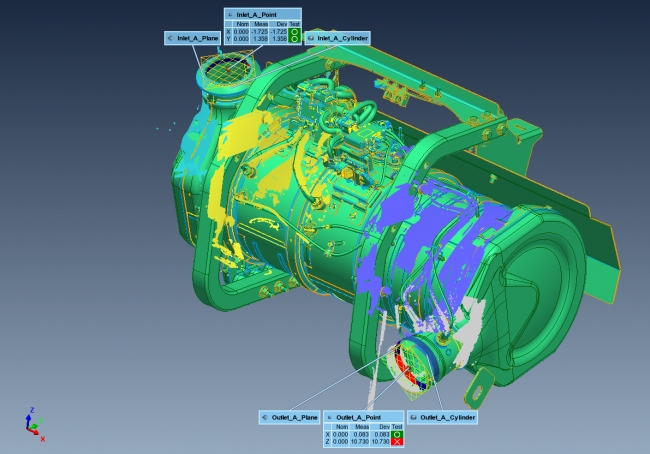

A robot-mounted Cobalt performing 100% automated inspection on an emissions assembly – inspection time is less than 65 seconds / Picture: FARO

Asking the Right Questions

Having worked at a major Original Equipment Manufacturer (OEM) prior to his position with Dynacraft, Caudillo had some experience with equipment that could help with the dilemma. It was just a matter of finding the right company with the right individuals to be able to bring the project forward. “I had talked to a few companies about this project and due to some technological constraints on their end, they could not provide what we were asking for,” says Caudillo. “When I approached Variation Reduction Solutions, Inc. (VRSI) and started talking with Evan Asher and Mike Kleemann, they were asking the right questions to be able to initiate and move this project from the ground floor to application.”

Building Things that Build Things

With a large team of highly experienced specialists, VRSI has been providing customers with state-of-the-art integrated solutions for vision, metrology, industrial robot guidance, and automated inspection since 1998. “Most everything that our group does is at least semi-custom,” says Evan Asher, project engineer at VRSI. “Each project is modified specifically to the customer’s application

and needs. We have some projects that are similar to others, but inevitably every customer has a slightly different process with slightly different requirements. Depending on what the problem is, we tailor the solution to that.” The ideal solution for Dynacraft would have to conform to a size profile allowing it to fit within an in-line work cell on the shop floor, be fully automated, and have the ability to measure a 6-foot long canister with 50 to 60 variations—all within 65 seconds.

The fully-automated, Cobalt / robot-based inspection system implemented by VRSI determines pass/fail status without human intervention / Picture: FARO

Choosing the Right System Components

“When a project requires integrating metrology with factory automation, there’s often a significant system engineering component,” explains Mike Kleemann, chief engineer and manager of the Aerospace group at VRSI. “We start with the requirements, and then work backwards to identify the

combinations of measurement, automation, control, and integration elements that need to come together for an optimal solution.” One of the system components that VRSI employed was a FANUC robot arm. For the metrology end of things, they chose the FARO Cobalt Array Imager. “Part of the reason we like to work with FARO, in general, is just because they’re a very reliable supplier,” says Asher.

“With the Cobalt, we found that both the accuracy and the field of view fit right into this application. And then once we started using it, it was very easy. It’s plug and play, you plug it into the computer and you can pretty much start rolling right away, so it proved to be relatively seamless. I would attest that the more straightforward part of the project was implementing the Cobalt.” Variations of surface finishes on the same assembly were also a consideration when choosing a scanner. “The surface [of the emission assembly] has multiple metal finishes,” explains Asher. “Some are shiny, some are dull,

and some are kind of in the middle, more like black dull metal. Also, the angle at which the Cobalt has to measure the surface [due to space restrictions] contributes to a difference. So, what we did was, for each of those positions we dialled into a different exposure setting. Sometimes one exposure setting was sufficient, sometimes we needed multiple exposure settings. To capture certain features effectively, we actually shoot three different exposures to achieve a proper measurement.” The high dynamic range of the Cobalt, and its ability to measure shiny surfaces, make it a natural choice for in-line factory metrology solutions.

The robot-mounted FARO Cobalt array imager helps VRSI and Dynacraft conquer the 100% in-line inspection challenge / Picture: FARO

Fitting in with Manufacturing Flow

“One priority for us was to be able to get the datums scheme according to their geometric dimensioning and tolerancing (GD&T) of the print,” explains Caudillo. “The location of the datum points on the assembly is very difficult to obtain because of where they are placed within the assembly. That is something that VRSI was able to do very well with the

Cobalt system and the robot.” Managing production-floor space requirements is no small challenge when designing a 100-percent inspection system. “Two of the four features we had to measure were in very tight quarters,” says Asher. “In order to measure all the features, the Cobalt had to be at a very specific angle. Between the field of view of the sensor, and the articulation of the robot, we were able to find the appropriate position to get those features.”

The Automation Situation

The Dynacraft facility runs 26 production lines. Twenty four of them are almost entirely manual, one other being semiautomatic—one operator and one robot. And then there’s the new QC line.

“This is actually the first project with the most automation for our facility,” states Caudillo. “Our facility is labour-intensive, so when we were tackling this project, we wanted to make that transition from being a manual, labour-intensive process to one that is highly automated. “This system is self-sufficient,” says Caudillo. “There is no operator involvement at all. The system will determine whether the part is good or bad, pass or fail, and then it will send that information to the end of the line to tell our operators in pack-out, whether it’s a good part or bad part. If it’s a good part, it continues through the pack-out process. If it is a bad part, the VRSI system will reroute that assembly manually to a rework station, where it will get reworked and then remeasured manually to verify that it is good; then it’ll return to the pack-out to ship out to our customer.”

Although at the time of this writing, 100-percent inspection is the exception rather than the rule in manufacturing, it is being called for more and more. It is already the norm in much of aerospace and medical device industries. As OEMs seek to mitigate risk factors, and suppliers seek to differentiate their organizations from the competition, no doubt it will come to the forefront as the premium QC process.