5 minute read

Interview: Amtek Plastics – a story of growth, investment & a positive future

Amtek Plastics UK is a plastic injection moulder who champions UK manufacturing and pride themselves on their individual, bespoke service.

Based in Devon, Amtek is experiencing rapid growth, despite the current economic climate, due to their investments in management software, workforce and marketing which helps enable them to exceed their client’s expectations, improve efficiencies and compete against overseas manufacturers.

Mark Amphlett, General Manager shares how Amtek will be developing over 2019, their challenges faced in 2018 and discusses how businesses can inspire youngsters to get into manufacturing.

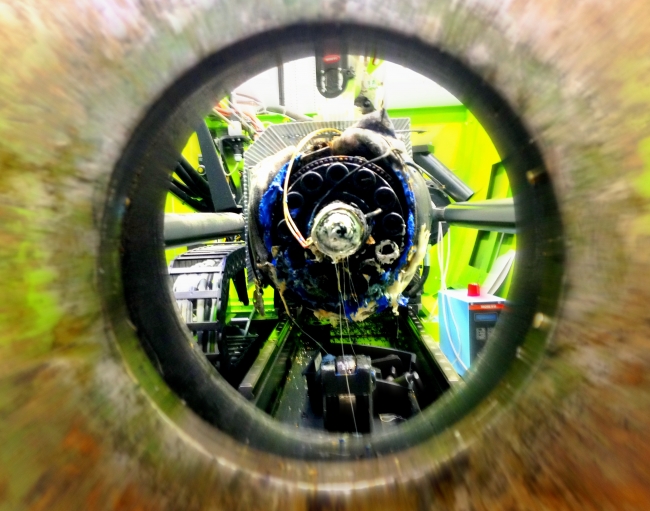

Amtek is experiencing rapid growth and making investments to improve efficiencies and compete against overseas manufacturers / Picture: Amtek Plastics

Success & growth

By the end of 2018, Amtek had grown by 20% compared to 2017 due to their continual investment in staff training, development in their ERP systems, and the expansion of their distribution and warehousing facilities.

“We work with a wide variety of companies from most sectors from aerospace and medical to construction, agriculture and automotive. Our machines have the capabilities to produce very bespoke products. We have found that our “sweet spot” is with medium to long-running projects that require attention to detail. Our very individual service means that businesses can make their products the best they can be.”

Despite the increase in growth, Amtek has found that there are always improvements to be made in the manufacturing process and these could be tweaked to increase efficiencies and capabilities. Amtek’s estimated current production rate is around 75 – 80%. Whilst this production rate is high, both expected and planned downtime are preventing the production rate to achieve over 90%. Therefore, over 2019 investment into improving these issues and speeding up the tool changing process, potentially with the introduction of automation, will be high on the agenda.

“We will also be improving our manufacturing efficiencies by utilising our current factory space and developing our ERP systems to make the process more automated with further emphasis on clients having control of their product’s manufacture.”

Overcoming challenges

Amtek’s main challenges in 2018 were from overseas competitors, especially from Asia. Even though UK manufacturing is becoming more competitive against overseas manufacturers, their often lower prices are still very attractive to businesses. Despite this, over recent years Amtek has seen a considerable increase in businesses reshoring their manufacturing back to the UK from overseas.

Investment plans in 2019 will be focused on improving production rate within the factory / Picture: Amtek Plastics

Amtek has seen off most of their Chinese and Taiwanese competitors by offering a higher quality product which clients can have direct access to throughout the entire process including greater communication, improved customer service and very quick lead times where clients to need to wait for air or sea freight – they can even offer a same day service.

“Our advice to other manufacturing businesses facing the same rivalry from overseas is to keep producing a superior product and shout about your services wherever you can from magazines to social media – you never know which source your next customer will come from. The UK Manufacturing sector has something amazing, and we need to club together to make UK manufacturers the go to. We are very proud to be part of the UK manufacturing scene.”

“To ensure that we keep our offerings diverse and suitable for every project, we have built relationships with businesses across a lot of sectors. For example, we love to work alongside expert product designers who ensure all projects are viable before clients invest in expensive tooling.”

Inspiring the engineers of the future

Amtek is also passionate about inspiring the younger generations to get involved with manufacturing and the plastic injection moulding industry. They are trying to find ways to attract the younger generations and to turn any misconceptions that they may have about manufacturing around.

“We use a variety of tools to entice youngsters in our industry, including embracing social media. We like to be very active on Facebook, Twitter and Instagram so we can show the world what we are up to and what plastic injection moulding is all about. We also use social media to highlight that manufacturing is so much than just machines, there is a whole world of opportunity including marketing, business development, design and sales to name a few. Not to mention the many chances to travel around the UK and abroad.”

Amtek is trying to find ways to attract younger generations and correct any misconceptions they have about manufacturing / Picture: Amtek Plastics

Locally to Amtek, a new University Technical College has recently opened up in Newton Abbot where students can gain qualifications in science and engineering. “We love to help, support and inspire the students whenever we get the opportunity – and going forward we will be looking into ways to get these youngsters interested in the world of engineering with projects, experiences and apprenticeships.”

“Here at Amtek, we like to enter our company and employees into a variety of National industry awards so they can gain experience in networking at these events and to celebrate their contribution to the business.”

“We also like to show our fun side with our sponsorships – currently we are sponsoring Tom Ingram and Toyota GB (Speedworks Motorsport), so not only is a great day out for our team it also shows that we aren’t all work.”

Future growth

As 2019 progresses Amtek is planning to invest in new ERP systems, new moulding machines and increase their use of robotics to make the whole manufacturing process more automated and smoother, whilst increasing efficiencies and capacity.

“We are always investing in our staff with continual training and development so we can always exceed our client’s expectations and so our staff can grow within the company and industry.”

Amtek works with business from a wide range of industries from aerospace and medical to security and agriculture, “We will look at any new markets with forward thinking companies that value quality, expertise and amazing customer service.” Recently, they have been talking to many companies about low volume specialist automotive work due to our current connection with the motorsport world via our sponsorship of Team Toyota GB – Speedworks Motorsport.

“We will also be looking at potentially increasing our workforce and factory space if our rate of growth remains high in 2019.”

Amtek is always on the lookout for new innovations and developing their own products to bring to market, “We are always thinking about launching new products ourselves, but we seem to be too busy helping our clients to develop theirs… watch this space!”

Amtek is planning to invest in new ERP systems, new moulding machines and increase the use of robotics at their factory / Picture: Amtek Plastics