4 minute read

Manufacture 2030: new sustainable manufacturing platform launched

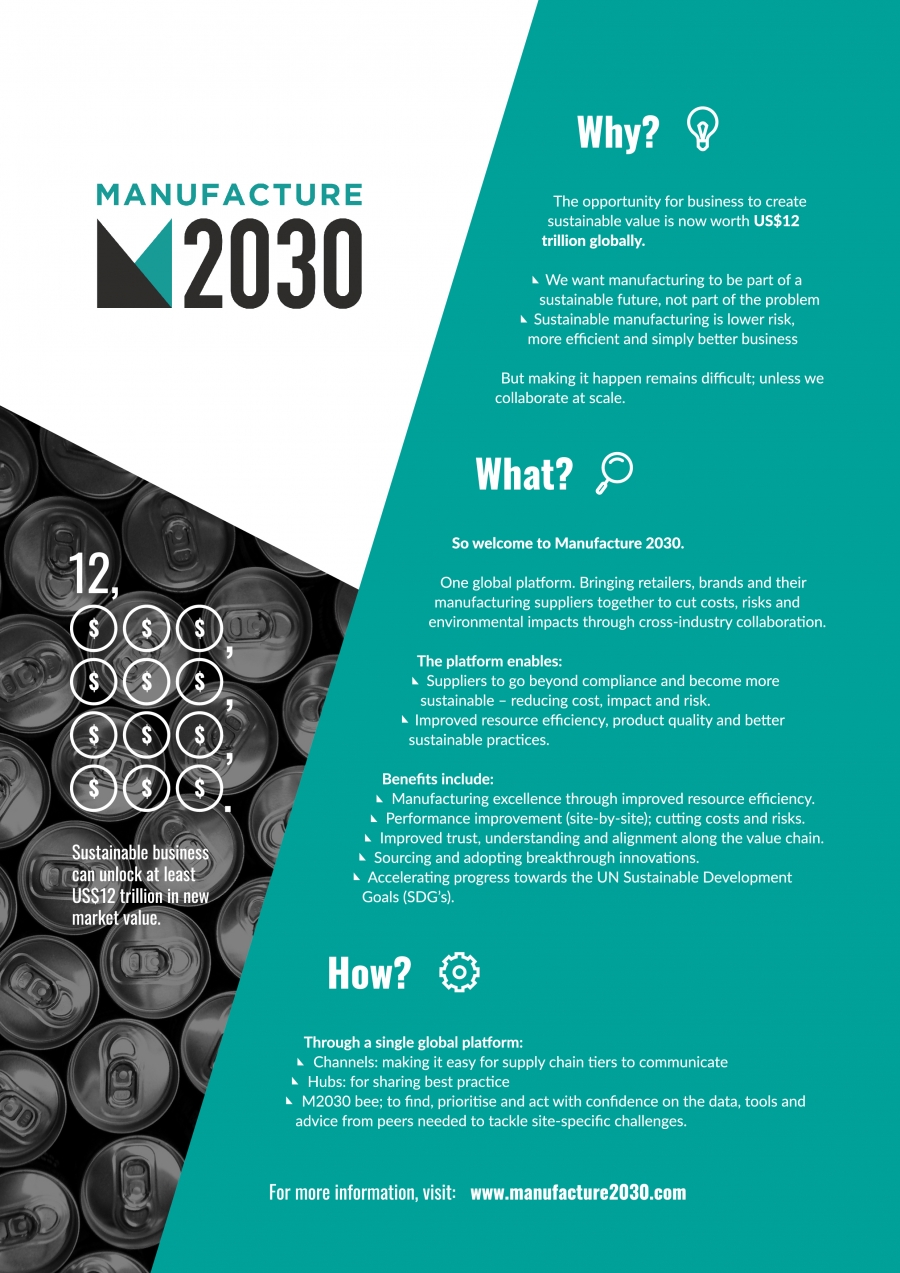

A new online platform will make sustainable manufacturing happen at scale for the first time by cutting costs, risks and environmental impacts through large scale, cross industry collaboration, say its creators.

The world’s leading digital collaboration platform provider for sustainable business, 2degrees, has launched a new solution for retailers, brands and their manufacturing suppliers. The global platform, Manufacture 2030, will help companies to cut their costs, reduce risk and minimise environmental impact through better supply chain and cross industry collaboration.

For most retailers and many large brands, 80% or more of their cost and risk sits in their supply chain. Whilst continuing to cut costs and eliminate risk from their own operations, these brands and retailers need to move beyond just squeezing suppliers to stay competitive. This includes finding new ways to collaborate with them to make further savings and reduce risk and impacts. Manufacture 2030 makes this possible, for the first time, at scale.

The Platform is accessible to businesses of all sizes, corporates and SMEs to collaborate and drive improvement via waste, water, energy and cost reduction. It builds upon 2degrees’ existing collaboration solutions that have helped remove over $40million of operational costs from just one food and drink supply chain.

Real-time monitoring on the M2030 dashboard / Image: 2degrees

Manufacture 2030 will enable retailers and brands to cost-effectively engage their suppliers in large numbers; helping suppliers and operational managers to improve the performance of their individual factories using collaborative tools.

It consists of three offerings – Supplier Engagement Channels, Collaboration Hubs and Tools:

• Supplier Engagement Channels – private spaces on the platform for supply chain owners to work with their suppliers to motivate them to go beyond compliance and achieve lower costs, reduced risk and become more sustainable.

• Energy, Waste & Water Hubs – open spaces focused on energy, waste and water, where operational managers from all companies, supply chains and select 3rd party experts can share best practice and experience.

• Tools – a peer-enhanced site-specific collaboration tool with resources to help managers cut costs, risks and impacts. Additionally, a second tool with benchmarking and reporting capabilities is available.

Manufacture 2030 launch event / Picture: 2degrees

Martin Chilcott, CEO of creators 2degrees explained more: “Most retailers and large companies now recognise there is a significant opportunity to reduce cost and risk and drive growth by being more sustainable. In fact, the Business and Sustainable Development Commission have put a global figure on it; US$12trillion and 380 million jobs by 2030. The challenge for businesses is that most of that opportunity sits in sprawling supply chains, and until Manufacture 2030 there has been no cost-effective way to unlock it. The case for sustainable business has never been stronger. And now with Manufacture 2030, it has just got a lot easier.”

Steve Evans, Director of Research in Industrial Sustainability at University of Cambridge, challenged manufacturers and added: “Manufacturers are not as efficient as they could be. 10% of costs are labour, which sees on average a 3% improvement in efficiency per year. 50% of costs are associated with resources like parts, material, energy, water and waste, which are only seeing a 1% improvement on average per annum. There is a huge untapped opportunity in resource efficiency. To make it happen, collaboration and knowledge sharing is essential, and if done properly, could see resource efficiency increase to 7% per annum, halving total manufacturing resource use in 10 years.”

Sarah Wakefield, Food Sustainability Manager for Co-Op, a founding partner of Manufacture2030 added a retailers view “Over the next few years, Co-op have ambitious plans to reduce the environmental impact of our products and actively support our suppliers to make sure our supply base is resilient to a changing climate. We are excited to be the founding retail partner of Manufacture 2030, which will enable our suppliers to share best practice and limit the time spent on reporting with the ultimate aim of reducing environmental impact. We firmly believe that working together with other major businesses and building trust among our suppliers are key in achieving our goals.”

What is Manufacture 2030?

Manufacture 2030 is a global digital collaboration platform, which brings retailers, brands and their manufacturing suppliers together to cut costs, risks and environmental impacts through cross-industry collaboration. It helps achieve manufacturing excellence through improved resource efficiency, by encouraging those along the supply chain to work together to help solve challenges. By encouraging cooperation along the supply chain, knowledge can be shared to help make the best use of resources, save costs and reduce risks and impacts.

Manufacture 2030 is accessible to businesses of all sizes, helping franchises, corporates and SMEs to engage their supply chain and drive improvement via waste, water, energy and cost reduction.

CEO, Martin Chilcott / Picture: 2degrees