3 minute read

ZF investing £30m at Peterlee factory

German technology company, ZF, is expanding production at its facility in Peterlee, County Durham, to address the growing demand for advanced camera systems that support automated driving. The company is investing around £30 million over the next two years to fund new production lines for the start of production of its next-generation camera technologies. It is also ramping up the recruitment of engineers, production specialists and apprentices.

ZF currently produce 6,000 cameras per day but this will rise to 10,000 per day from 2019 / Picture: ZF

“ZF develops and manufactures technologies that are significantly helping to reduce emissions and accidents,” said Robin Finley, director of the ZF plant in Peterlee. “In pursuit of this goal, the company combines precision engineering with digital technology to help enable vehicles to See, Think and Act – sensing their environment, processing the data and responding accordingly. Advanced camera technology is a major contributor to active safety systems that help enhance road safety.”

ZF offers a full portfolio of sensors needed for vehicles to detect their surroundings, including radar, lidar and cameras. ZF Peterlee produces safety cameras, with output currently running at 33 thousand units per week. In 2019, the factory will start production of a next-generation system incorporating Mobileye’s EyeQ4 technology which has powerful object recognition capabilities (eight times more than the current generation). Called S-Cam 4, major car companies will use this camera to support specific road safety and automated driving tasks including Highway Driving Assist and Traffic Jam Assist. By 2020, production of this sensor is expected to be around 70k units per week.

ZF employ around 880 people currently, but this will rise with the introduction of the next-generation cameras / Picture: ZF

As one of the largest employers in the UK North East of England, ZF has seen a steady increase in growth over the past few years and currently employs around 880 people. Preparations for the launch of the next-generation cameras mean staffing levels at the plant are expected to increase again – to around 950 by the end of 2018.

The site has been producing high-specification automotive safety electronics for more than a decade and with the introduction of advanced driver assist systems, the plant turned their assembly processes and expertise to the challenge of automotive camera production in 2013.

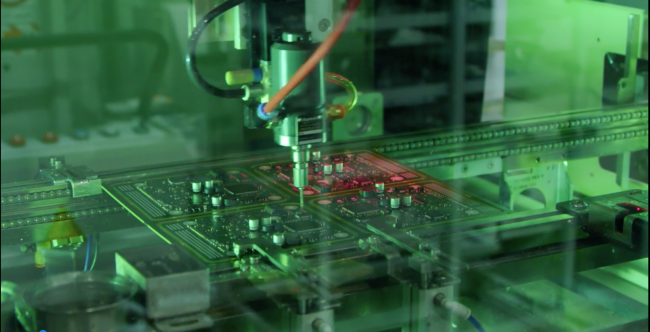

“Cameras for cars are not like typical consumer cameras: they must meet high levels of functional safety and be capable of operating in various environmental conditions for many more years. This makes the quality, durability and reliability requirements higher,” said Finley. “This is achieved with advanced, highly automated production processes and highly trained operators.”

Peterlee is one of only three ZF locations globally producing this state-of-the-art technology. ZF cameras support current driver assist systems including automatic emergency braking (AEB) and lane assist functions. With around 420 individual components coming together to make each camera, each one takes approximately 23 seconds to assemble and test.

“The team spirit of the people and their determination to continuously improve has made Peterlee an incredible success,” says Finley. “The contribution of many people has enabled our operations to grow and to meet the new opportunities that the introduction of automated vehicles presents.

Each camera takes just 23 seconds to assemble & test at the Peterlee plant / Picture: ZF

ZF is investing in the development of local talent at Peterlee, expanding its apprentice scheme and working with local education organizations to support the changing training needs of our workforce”.

The factory currently offers apprenticeships in engineering and maintenance and is expanding the scheme to include other disciplines such as human resources, quality, and logistics. The factory is on target to double the number of apprenticeships in place by the end of 2017.

“Anybody with the right attitude and commitment can progress at ZF,” says Finley. “It has never been a more exciting time to join the automotive industry and here at ZF Peterlee, we’re working on technology that is at the heart of the changes generating this excitement.”