5 minute read • published in partnership with Bosch Rexroth

Bosch Rexroth focus on upskilling British industry

When it comes to reducing downtime and improving productivity, specialist knowledge and expertise create a crucial advantage in a competitive marketplace. To achieve long-term, sustainable growth, modern manufacturing facilities are turning to talent development and training programmes to fill their skills gaps and ensure optimum efficiency.

As a leading specialist in drive and control technology, Bosch Rexroth is perhaps best known for providing hydraulics, electric drives and controls, gear technology and linear motion and assembly technology. However, the business also has a unique level of technological expertise and experience, which is used in the development of training courses and the provision of training systems and tools.

Hands-on Hydraulics training

Hydraulic systems are widely used in many areas of industry. At a basic level, hydraulic systems work by pressurising liquid to create a mechanical force. This kind of system is common in many industries, including construction equipment, aeroplanes, cars, manufacturing, subsea and many more. When dealing with high pressure, heavy duty equipment, ensuring that both experienced and new technicians undertake comprehensive training is vital.

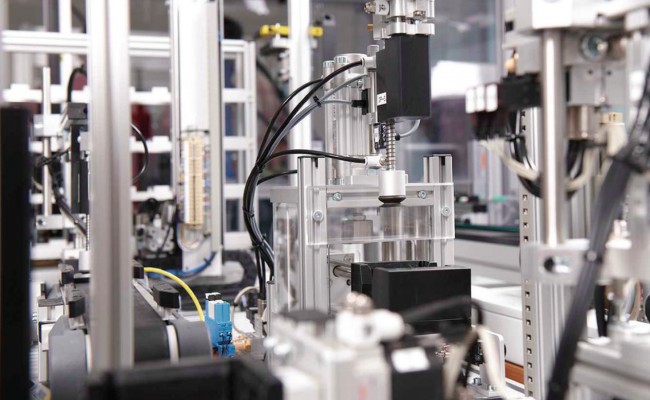

Bosch Rexroth has a unique level of technological expertise and experience, which is used in the development of training courses and the provision of training systems and tools / Picture: Bosch Rexroth

No matter how complete a company’s commitment is to training, it is generally accepted that not all training can be accommodated in-house and there is therefore a reliance on external partners and institutions to deliver at least some aspects of it. As a recognised leader in the field of industrial drive and control technology, Bosch Rexroth’s training academy is able to bundle industrial technologies, application-based teaching media and practical expertise to create a series of training courses that help to plug the knowledge gap in industry.

Jim Malin, Hydraulic Training Manager at Bosch Rexroth says, “As technological developments continue apace, all industrial sectors face a constant battle to attract and retain the highest calibre individuals. Only by ensuring the workforce of today and tomorrow are constantly educated, will we be able to really take advantage of new and upcoming technologies. By promoting continuous improvement through structured, practical, hands-on training, we aim to help equip industry with the relevant skills, understanding and flexibility to deal with the future of British industry.“

Helping Industry meet the skills gap

As well as providing an extensive range of training courses, Bosch Rexroth also works hand-in-hand with other training providers – including schools, colleges and universities – to ensure that the equipment they are using to deliver training is fit for purpose and reflects the latest industry technology.

By providing such training facilities a range of training rigs – including hydraulics and pneumatics rigs as well as Mechatronic training rigs for teaching automation, PLC programming, safety PLCs, sensor technology and Industry 4.0 applications – Bosch Rexroth is playing a crucial part in upskilling British industry and preparing workers for the future.

Bosch Rexroth’s WS290 hydraulic training rig offers unlimited options for creating practical and demanding tasks in the fields of on/off hydraulics, proportional and closed loop control valve technology. Specifically designed as a training rig, the system is an ideal way to upskill those involved in the maintenance and management of hydraulics systems – as well as those who are new to the industry.

The Advanced Manufacturing Training Centre

With a focus on upskilling British Industry and ensuring that it remains competitive, the Advanced Manufacturing Training Centre, Coventry, is focused on developing, maintaining and building upon the vital skills required by manufacturing graduates, technicians, engineers and managers. With a specific focus on working with apprentices and closing the current skills gap which is threatening the industry, it is vital that the AMTC uses the very latest technology to deliver training that will give people the practical skills required in industry. For this reason, the AMTC work closely with Bosch Rexroth, utilising both their hands-on expertise and their training rigs to deliver high quality training.

James Wagstaff, Senior Trainer and Apprentice Programme Manager at the AMTC, says: “The training rigs supplied by Bosch Rexroth are great because they replicate everything that you’d expect to find in the field, which really allows us to really prepare workers for industry. As well as offering hands-on training, the rigs allow us to set up fault finding exercises which replicate real-life scenarios. They are also really simple to set up, while also offering great functionality – a rare combination! The Rexroth rigs provide a perfect balance between academia and industry providing learners with a fantastic opportunity to go into the workplace, fully prepared to enhance the company workforce and overcome difficult situations.”

Bosch Rexroth provides an extensive range of training courses and also works hand-in-hand with other training providers / Picture: Bosch Rexroth

R.N.L.I College

For the Royal National Lifeboat Institution, training and having equipment that works as it should is fundamental to saving lives. The RNLI College, based in Poole, is responsible for ensuring that their 80-strong team of technicians have the skills required to look after a large range of sophisticated and expensive lifesaving kit – undertaking repairs, maintenance and modifications to the lifeboat fleet, as well as launch and recovery systems and lifeguard equipment.

Bob Lee, Machinery Training Instructor at the R.N.L.I college explains, “We have a dedicated hydraulic training room on site at our college in Poole, which features five of Bosch Rexroth’s hydraulic training rigs – all of which are used to train and upskill our team of technicians. I first saw the rigs when I attended a training course delivered by Rexroth at their Wakefield plant. After chatting to their training team, I decided to invest in some of the rigs for the college – the fact that they were able to make them bespoke to meet our specific training needs was an additional bonus.

“The rigs allow us to teach our technicians basic hydraulic principles and help them to understand the physics at play by focussing on a physical system rather than proving the theory with mathematics. As well as the obvious safety benefits offered by using a rig for training rather than a working piece of machinery, they also allow us to give technicians schematics to build their own circuits rather than just practising on existing ones. By reinforcing the theory with practical hands-on training, we’re able to better equip our technicians for the kind of real-life applications they’ll encounter – all of which is vital to keep the R.N.L.I. operational and save lives.”

National Fluid Power Centre

As a BFPA certified CETOP Education Centre, the National Fluid Power Centre (NFPC) based in Worksop, is an approved training provider for many ‘blue-chip’, industry-leading corporations. Boasting 3 fully equipped technical centres with over 3 million pounds worth of up to date equipment, the NFPC prides itself on being at the forefront of specialist training centres for those involved in the maintenance and management of fluid power systems. As such, the college works with industry-leading suppliers, such as Bosch Rexroth, to provide industry-leading training rigs and equipment that closely reflects what can be found in the field.

John Savage Principal at the NFPC says: “The skill gaps are widening and industry is changing, with equipment and technical specifications/functionality becoming more technically advanced. Staff require more skills to keep up with knowledge requirements. The Rexroth training rigs allow students to apply skills and gain experience of working with an integrated system of hydraulics and electronics. The rigs give them the ability to compare the outputs and performance of using hydraulics and progressively adopting electronics for mobile and industrial use. Ultimately, it is really useful for them to get their hands-on practical training systems which will equip them for industry.”

Gen2

Also committed to closing the skills gap in British manufacturing, Gen2 offers a range of training courses in Cumbria – including the training of new and apprentice technicians and running day-courses for those already in industry.

Having recently invested in a hydraulics training rig, Maurice Parnaby, Project Engineer at Gen2, says, “The rig is being used in conjunction with a software database called Autosym to design and build the circuits on a magnetic board. Following this the circuit is built on the rig and finally faults are put in for the students to find. We are very happy with the functionality and build of the rig, which helps us to ensure that our students are fully equipped when it comes to working in the field.”