2 minute read

British Steel secures two major rail contracts in Italy

British Steel has won two multi-million-pound contracts to supply 86,000 tonnes of rail to Rete Ferroviaria Italiana (RFI), the manager of Italy’s railway infrastructure.

The agreements – which include the delivery of 18,000 tonnes of its unique premium Stress-Free (SF) heat treated rail – quickly follow two other major deals British Steel has secured with national rail operators.

In September, Network Rail announced it was extending its supply contract with the company for two years and in October, Infrabel, which operates Belgium’s railways, signed a four-year agreement.

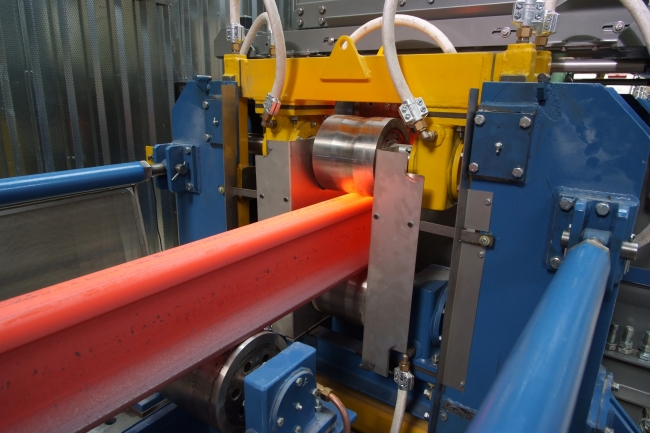

British Steel has won two multi-million-pound rail supply contracts in Italy / Picture: British Steel

Richard Bell, British Steel’s Commercial Director Rail, said: “We’re delighted to have been awarded these contracts which reflect the excellent working relationship we have with national rail operators like Rete Ferroviaria Italiana (RFI) and our ongoing commitment to delivering high quality rail in Italy.

“For each of our agreements with RFI, Network Rail and Infrabel, we’ve had to go through a rigorous tendering process so these contracts are excellent demonstrations of our ability to provide first class products and services in highly competitive markets.”

Of British Steel’s latest contracts with RFI, one is for 68,000 tonnes of its standard grade rail and the other for 18,000 tonnes of its premium heat-treated SF350 rails. Both deals are for rail in lengths of 108 metres.

The premium SF heat treated rails are designed for use in curved or heavy haul tracks where wear and fatigue are significant issues.

British Steel first made its premium heat treated rail in 1984 and has since supplied more than one million tonnes of it across six continents – enough to build a railway from London to Beijing.

The steel for the SF heat treated rails is manufactured at the company’s headquarters in Scunthorpe, England, before being transported to British Steel’s state-of-the art rail rolling facility in Hayange, France. Once there, it’s rolled into rails and further strengthened using British Steel’s special heat treatment process.

The unique manufacturing process uses inductive heating followed by compressed air cooling in one continuous movement. This process is so tightly controlled that unlike competitors, no roller-straightening is required afterwards, resulting in a more durable ‘stress-free’ rail.

British Steel’s SF rails deliver a typical threefold increase in the defect size needed to initiate fatigue in the rail foot compared to standard R350HT rails. If fatigue does start, the low residual stress in SF350 doubles the lifetime to failure, compared to standard on-line/in-line heat treatment methods.

Test results showed that to achieve the same fatigue life (5 million cycles) British Steel’s SF rail can withstand 67% more fatigue stress than conventionally heat-treated rails.