2 minute read

CJR Propulsion invests £4m at its Southampton facility

Southampton-based propulsion specialist, CJR Propulsion, has announced the installation of £4million of new manufacturing equipment at its South Coast facility.

Representing one of the marine industry’s largest single investments of 2018, the newly appointed apparatus, and related software, will integrate seamlessly with CJR’s existing CFD (computational fluid dynamics) department and create an end-to-end, data-driven design and manufacturing process, boasting high levels of automation.

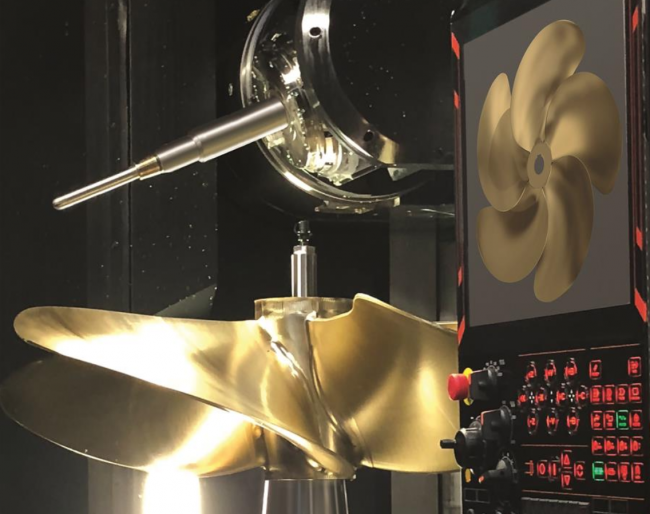

The latest arrivals include machine-controlled, robotic mould-making, multiple 5-axis CNC machining cells, pick-and-place delivery and storage technology and the automation software required to integrate each stage of the process.

CJR Propulsion has announced a £4m investment in new manufacturing equipment and infrastructure / Picture: CJR

CJR hopes the new equipment will help position the company as one of the world’s most technically advanced propulsion experts and, over time, help improve quality and efficiency standards across the industry.

CJR Propulsion’s managing director, Mark Russell, said: “Many in the propulsion industry are still happy to rely on individual experience and ‘a good eye’ to make decisions we know are critical to the performance and longevity of a propulsion system. We are simply not comfortable with that. However, fundamentally, this isn’t about CJR, these investments are about delivering better products to our customers, and on that front, the impact will be significant. Accuracy, performance, efficiency, longevity and ride comfort can all be improved and we are looking to reach a level of precision that is above even Class S standards.

“On a recent project, the customer estimated they will save ten percent on their annual fuel bill because of our props, so there are real, tangible benefits for boat builder or end user. We also know we can cut the time from initial contact to delivery by over 60 percent on new projects, without adding anything to the final cost so, across the board, this is great news for all our clients.”

The bespoke equipment has been designed and built specifically to meet the requirements of CJR Propulsion’s growing customer base and will enable CJR to offer its unique approach to ever-larger projects around the world.

The investment includes machine-controlled, robotic mould-making, multiple 5-axis CNC machining cells, pick-and-place delivery and storage technology / Picture: CJR

To house the new equipment, CJR Propulsion has acquired an adjacent facility in Southampton, increasing its manufacturing space by more than 50 percent. The company is also providing existing staff with the opportunity to retrain to ensure the increased levels of automation doesn’t result in job losses.

“We are delighted that even as we automate swaths of the design and manufacturing process, we will ensure the continued employment of our team. Our already highly-skilled workforce will be receiving ongoing training and we actually expect to be increasing our head count further to ensure our growth continues,” Russell concludes.