2 minute read

Penso launches new composite body assembly facility

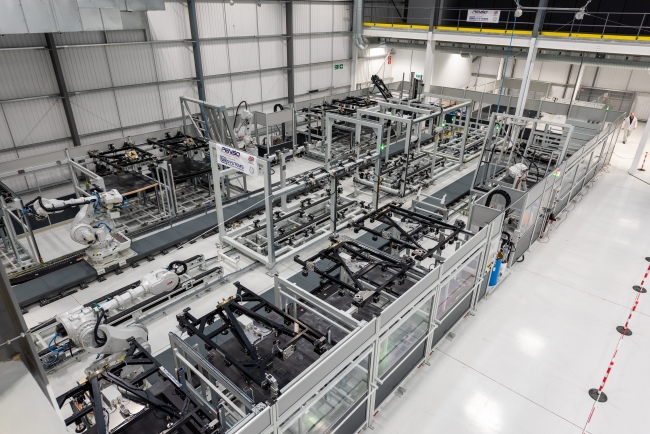

Coventry-based Penso has launched a new flex-automated carbon fibre body assembly plant to manufacture ultra-lightweight commercial vehicles with industry-leading payloads for the home delivery sector. The flexible robot assembly line allows the build of more than 30 van body variants amongst other vehicle formats, producing a finished van every 42 minutes.

The new facility will support the Flexible Lightweight Architecture for Volume Applications (FLAVA) project.

In 2017, Penso and Solvay formed a consortium to deliver the FLAVA project. The consortium was awarded government match funding by the Advanced Propulsion Centre (APC) as part of a £16.3m investment to accelerate the use of high volume lightweight composite structures within the automotive industry.

Penso has launched a new flex-automated carbon fibre body assembly plant to manufacture ultra-lightweight commercial vehicles / Picture: Penso

The project was split into five key areas with lead partner Penso focusing on:

• Product design of an ultra-lightweight modular van platform

• Component manufacture

• Flexible automated modular assembly

• Affordable business model

• Significant emissions reduction of CO2 and NOX

Mercedes-Benz Vans UK also became a project partner and the overall goal was to demonstrate significant emissions reductions through vehicle light-weighting whilst generating an attractive business model to ensure maximum market acceptance.

Penso has developed a commercial vehicle body system to provide a wide range of delivery vehicles capable of meeting the growth in the home delivery market with a vast improvement in the environmental impact of these models. The flexible design approach allows for every derivative from refrigerated home grocery deliveries to parcels and white goods within the 3.5t GVW sector.

Through the intelligent use of Penso’s proprietary composite sandwich panel technology, Penso has reduced the cargo body mass by up to 40% compared to traditional materials and manufacturing techniques. In addition, the sandwich panel technology utilises over 5,000 recycled plastic bottles within its construction to deliver cold chain insulation requirements alongside long term durability.

Penso has developed a commercial vehicle body system to provide a wide range of delivery vehicles capable of meeting the growth in the home delivery market / Picture: Penso

Over the last six months, Penso has undertaken significant prototype testing at numerous third party UK test houses, in order to validate the key performance requirements of the vehicles.

Penso managing director, Daniel Hurcombe, said: “The respective designs of the carbon fibre e-grocery and e-delivery vans provide huge payload increases to both refrigerated and dry freight customers. Fuel economy, labour and vehicle efficiency savings enable an unrivalled total cost of ownership. We have been overwhelmed with the response from the home delivery industry in regards to the benefits that the product can achieve.”