2 minute read

AMRC’s robot research cuts the cost of producing aircraft components for BAE Systems

The Advanced Manufacturing Research Centre (AMRC), a part of the High Value Manufacturing Catapult network, is working on a research project to enable robots to accurately machine holes in composite aircraft components, has matured into a production system and is on track to save BAE Systems millions of pounds in capital and operational costs over the coming years.

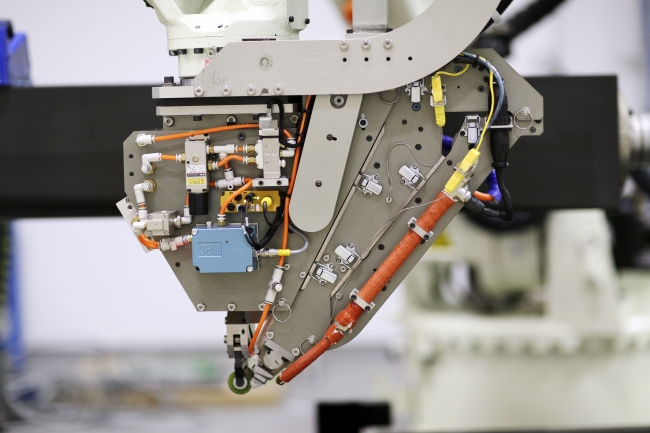

The robotic countersinking technology was developed through collaborative research, led by the AMRC and involving KUKA Systems UK. The development technology derisked the process enabling the design of a production system. This production system has now been installed at BAE Systems in the UK, where it will be used to processes a wide range of composite components for military aircraft.

The AMRC collaborated with BAE Systems on a research project which has developed into a production system that is on track to safe millions of pounds / Picture: HVMC

Ben Morgan, head of the AMRC’s Integrated Manufacturing Group, said: “We have been able to develop a cost-effective solution with the latest state of the art control systems.

“The architecture of the system will allow the technology to evolve over time and embrace the ideas behind Industry 4.0. We’re now advancing the development system further, enabling process monitoring and generating ‘Big Data’. Analysis of this data, i.e. ‘Data Mining’ will provide an understanding of quality in process.”

The robotic countersinking technology includes the use of multiple robots to automatically handle composite components and then countersink high tolerance pre-drilled fastener holes.

Non-contact metrology integrated with the machining robot locates predrilled holes and corrects the robot’s position before countersinking.

A separate robot provides support to the component eliminating expensive holding fixtures. The system is controlled via the latest S7 Siemens programmable login controller (PLC) and includes the use of augmented reality to aid component fixturing.

Austin Cook, from BAE Systems, added: “Since we began working with the AMRC in 2006 it has supported the development of key manufacturing technologies ranging from high performance titanium machining to advanced automation for military components.

“We collaboratively research new innovative solutions at various maturity levels. The AMRC, and in particular the Integrated Manufacturing Group, has helped us mature the robotic countersinking technology from technology concept to full scale production demonstrator, de-risking along the way, and helping to catapult the capability into our business.”

Follow this link for more information on the AMRC Integrated Manufacturing Group