4 minute read

SMR nuclear power station project takes step forward

An SMR consortium, led by Rolls-Royce, which is creating a compact nuclear power station known as a small modular reactor (SMR), has revealed its latest design. The consortium has also announced an increase in power as it completes its first phase on time and under budget.

It is aiming to be the first design to be assessed by regulators in the second half of 2021 in the newly-opened assessment window, which will keep it on track to complete its first unit in the early 2030s and build up to 10 by 2035.

As the power station’s design has adjusted and improved during this latest phase – with more than 200 major engineering decisions made – the team has optimised the configuration, efficiency and performance criteria of the entire power station, which has increased its expected power capacity, without additional cost, from 440 megawatts (MW) to 470MW.

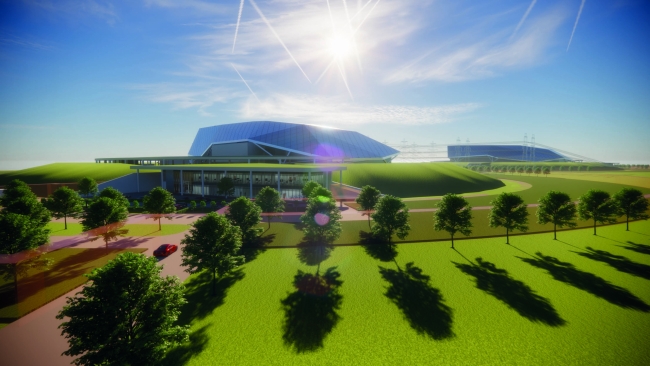

Rolls-Royce is leading a consortium that could create thousands of new jobs by building new small modular reactor power stations. Up to 80% of the power station components would be made in UK factories / Picture: Roll-Royce

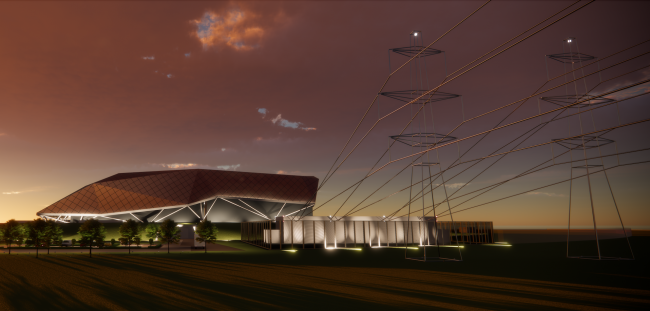

The refreshed design features a faceted aesthetic roof; an earth embankment surrounding the power station to integrate with the surrounding landscape; and a more compact building footprint, thanks to successes optimising the use of floor space.

With a focus on continuing its progress at pace, the UK SMR team is transitioning from being a collaborative consortium to a stand-alone business, which will deliver a UK fleet of power stations to become a low carbon energy bastion alongside renewables, while securing exports to make the power station a key part of the world’s decarbonisation toolkit.

The power station’s compact size makes it suitable for a variety of applications, helping decarbonise entire energy systems. Each power station can supply enough reliable low carbon power for around one million homes, or be used to power net zero hydrogen and synthetic aviation fuel manufacturing facilities, desalination plants or energy intensive industrial sites.

Tom Samson, chief executive officer of the UK SMR consortium, said: “Nuclear power is central to tackling climate change, securing economic recovery and strengthening energy security. To do this it must be affordable, reliable and investable and the way we manufacture and assemble our power station brings down its cost to be comparable with offshore wind at around £50 per megawatt-hour.

“As we reach the end of our first phase, I’m proud that our team has designed a product that can be commoditised to provide the scale required to be a key part of the world’s decarbonisation efforts. We are ready to go and hope to be first in line to start the rigorous Generic Design Assessment process in the autumn of this year.”

The latest SMR design is set to the first to be assessed by regulators in the second half of 2021 / Picture: Rolls-Royce

In the UK alone, the power station programme is forecast to:

• create 40,000 regional UK jobs by 2050

• generate £52bn of economic benefit

• have 80% of the plant’s components sourced from the UK

• target an additional £250bn of exports – memoranda of understanding are already in place with Estonia, Turkey and the Czech Republic

• cost initially c.£2.2bn per unit dropping to £1.8bn by the time five have been completed

• operate for at least 60 years

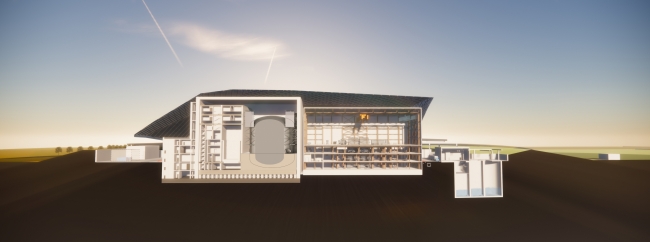

The design, which will be finalised at the end of the regulatory assessment process, proposes that all used fuel will be stored on each site for the lifetime of the plant.

The power station’s design cuts costs by using standard nuclear energy technology used in 400 reactors around the world, so no prototyping is required. The components for the power station are manufactured in modules in factories, before being transported to existing nuclear sites for rapid assembly inside a weatherproof canopy. This replicates factory conditions for precision activities and further cuts costs by avoiding weather disruptions.

The whole sequence secures efficiency savings by using streamlined and standardised processes for manufacturing and assembly, with 90% of activities carried out in factory conditions, helping maintain extremely high quality. In addition, all spoil excavated will be reused on site to build the earth embankment, removing the need for it to taken off site, reducing road journeys that are both financially and environmentally costly.

The SMR consortium has revealed its latest design and an increase in power as it completes its first phase on time and under budget / Picture: Rolls-Royce

The consortium members feature a host of nuclear engineering, construction and infrastructure expertise in Assystem, Atkins, BAM Nuttall, Jacobs, Laing O’Rourke, National Nuclear Laboratory, Nuclear Advanced Manufacturing Research Centre, Rolls-Royce and TWI. Consortium colleagues have worked in integrated teams – remotely during Covid – across all aspects of the first phase of the programme to progress the design and ensure innovations were targeted only at elements of the power station that would drive down costs.

The power stations will be built by the new UK SMR business, before being handed over to be operated by power generation companies. In November 2020, the consortium signed a memorandum of understanding with US giant Exelon Generation to pursue the potential for Exelon Generation to operate compact nuclear power stations both in the UK and internationally.