4 minute read

£53m of funding to support digital manufacturing research

The government has unveiled £53m of new funding to support the creation of five new digital manufacturing research centres, a new digital supply chain innovation hub, and 37 individual projects. The investment will help to digitalise and transform manufacturing supply chains, and drive the development of the latest digital manufacturing technologies.

The funding has been awarded through the national Made Smarter programme, a collaboration between the UK government and industry designed to support the development and increase the use of these emerging technologies. Adoption of the latest data-driven innovations, such as the use of AI and blockchain in supply chains, or advanced robotics and smart machines in manufacturing, will help manufacturers to increase productivity, become more sustainable and boost competitiveness.

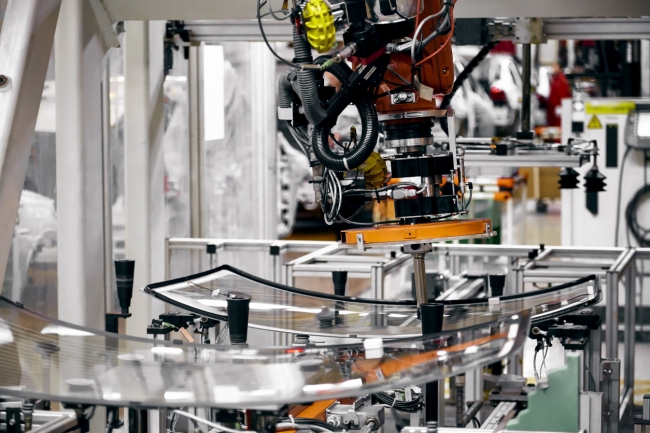

The government has announced £53m of new funding to help manufacturers boost productivity with digital technology / Picture: Getty/iStock

Nearly £25m will be invested in five new industry-sponsored research centres based in universities throughout the UK, including at the University of Strathclyde and University of Nottingham. Helping to make supply chains faster, more efficient, and more resilient, each centre will focus on a different area of manufacturing and include:

– Digital Medicines Manufacturing Research Centre, based in Strathclyde, Cambridge and Loughborough, aims to create digital supply chains that enable medicines to be supplied on demand and enable clinical trials to operate more flexibly.

– Research Centre for Smart, Collaborative Industrial Robotics, based in Loughborough, Strathclyde, Cranfield, Bristol and Warwick, will look to eliminate barriers to adopting robotics and accelerate their widespread use in manufacturing.

– Research Centre for Connected Factories, based in Nottingham, Cambridge and Sheffield, will work to create a ‘Morphing Factory’ where production can be easily repurposed in response to changing market demand, for example, during the pandemic when drinks manufacturers transformed production lines to make hand sanitiser.

– Materials Made Smarter Research Centre, based in Strathclyde, Cambridge and Loughborough, will work on overcoming technological challenges preventing adoption of new materials and manufacturing processes needed to become more sustainable and help achieve net zero emissions.

– People-Led Digitalisation, based in Bath, Nottingham and Loughborough, aims to achieving the highest level of manufacturing productivity by increasing the digital knowledge and awareness of manufacturers.

Minister for investment, Lord Grimstone, said: “Improving productivity and becoming more competitive is not just about sophisticated manufacturing, but also about smarter manufacturing, and we want to make it as easy as possible for companies large and small to make the changes needed to take full advantage of the innovative technology being developed.”

Five new research centres, a new digital supply chain innovation hub, and 37 individual projects will benefit from the funding / Picture: Getty/iStock

A further £18m has been awarded through the Digital Supply Chain Competition to 37 winning projects to support the development of innovations designed to help manufacturing supply chains become more productive and sustainable. Jaguar Land Rover are among the winning projects, and will be investigating the use of blockchain technology when tanning leather to improve traceability and reduce environmental, social and economic risks.

£10m in funding has also been awarded to the new Made Smarter Innovation Digital Supply Chain Innovation Hub to develop breakthrough solutions that create supply chains that are fully connected, resilient and sustainable. Delivered through a collaboration led by Digital Catapult, and bringing together businesses, universities and research technology organisations, the new hub network will help make innovation more accessible for a wide range of potential businesses, including manufacturers and technology providers large and small. The hub will provide access to clusters of test beds and other practical laboratories.

Made Smarter Innovation Challenge Director, UKRI, Chris Courtney, added: “Digital technologies have the power to radically transform how we manufacture and deliver the products and services of today and the future delivering a productive, sustainable and flexible manufacturing sector and enhancing the future of work within it. There are enormous opportunities to innovate in this area, we have world leading industries, a powerful scientific and research community and a vibrant technology sector. It is vital we form a vibrant connected ecosystem from applied research to industrialisation in order to fully capitalise on that potential.”

Jeremy Silver, CEO of Digital Catapult, said: “The opportunity for innovation in manufacturing supply chains is incredibly broad. The Made Smarter Digital Supply Chain Innovation Hub will demonstrate how the tangible impact of emerging digital technologies can affect the nation’s supply chains, mitigating against the kinds of component shortages experienced during the pandemic, boosting efficiency, reducing waste, and supporting some of the UK’s most important industrial sectors through fostering a culture of innovation.”