2 minute read - 6th September 2022

Kleanbus reveals modular technology for electric buses

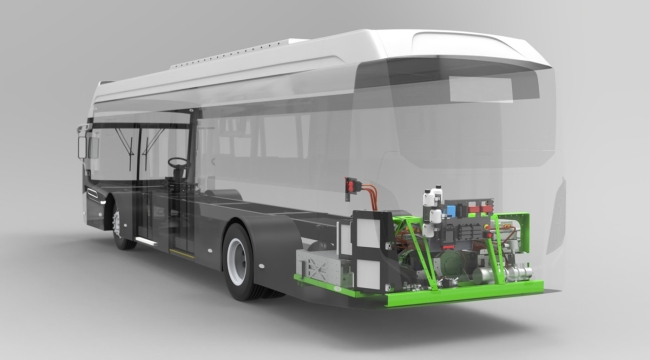

Kleanbus, a UK-based bus repowering company, has revealed the first images of its advanced modular platform technology, which can turn any bus, whether single or double decker, from diesel to fully electric quickly and cost-effectively. The firm says electrification is the most viable way for bus operators to go green, but new electric buses are expensive and can take many months to join a fleet from order placement to delivery.

Repowering – removing the diesel engine or hybrid powertrain from an existing bus, and replacing it with a fully electric powertrain – may prove to be the fastest and most cost-effective way to transition the UK bus fleet to zero emission. Kleanbus says electric repowered buses will cost one fifth of a new electric bus, with a third of the operating costs of diesel buses.

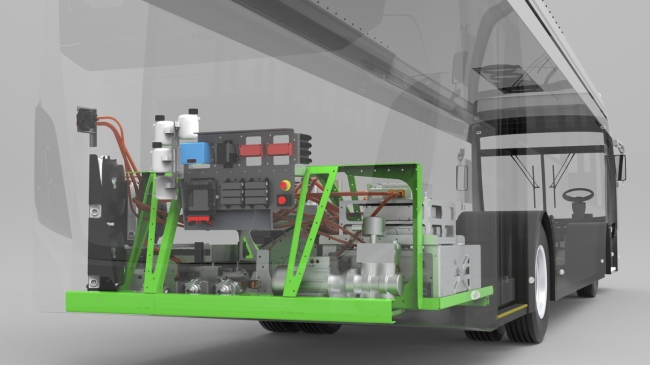

From its state-of-the-art 9,000 sq ft facility based in the east of England, the Kleanbus repower programme consists of a full evaluation of the vehicle, removal of its diesel engine and all associated ICE components, scanning and prototyping of the vehicle’s interior, design of a bespoke platform, installation of a new e-drive, build, full testing process and final certification. Once a bespoke e-drivetrain has been designed and tested, it takes less than two weeks to repower an individual bus, getting the vehicle back in service in as little time as possible.

Kleanbus has revealed its new modular repower technology which can turn any bus from diesel to fully electric / Picture: Kleanbus

Joe Tighe, co-founder and CEO of Kleanbus, said: “With 97% of UK buses powered by diesel engines that emit large amounts of carbon, oxides of nitrogen, and particulate matter – and a staggering 35,000 of them on the road – the country faces a major challenge to rapidly decarbonise this vital transport sector and is struggling to move quickly enough. Replacing these vehicles with new electric buses is very expensive for private companies and government subsidies will take many years given fleet turnover rates. Kleanbus offers a fast and efficient way towards zero-emissions, making buses cleaner, quieter, more comfortable, and more valuable assets for operators.”

Combining electric powertrain components from leading Tier 1 suppliers with its own integration technology and proprietary software, Kleanbus says its platform system is technology agnostic, nimble and adaptable and that it can take advantage of the very latest componentry, enabling it to leverage a wide variety of batteries and motors, creating purpose-built e-powertrains tailored exactly to a bus operator’s needs.

The e-motors used by Kleanbus also do not have permanent magnets, so use no rare earth materials at all, demanding less of the planet’s resources and limiting the damaging impact of rare earth metals production.

Electric repowered buses will cost one fifth of a new electric bus, with a third of the operating costs of diesel buses / Picture: Kleanbus