5 minute read

Academy announces engineering awards for transformative work during Covid-19 pandemic

The Royal Academy of Engineering has recognised the exceptional contributions that the UK engineering community has made during the Covid-19 pandemic by making a number of President’s Special Awards for Pandemic Service.

From those who kept essential services and infrastructure effective in unprecedented circumstances, to those who helped protect the NHS, the awards have been made to teams, organisations, individuals, collaborations and projects across all technical specialities, disciplines and career stages. Specially commissioned silver medals will be presented to all 19 winners later this year.

Winners include Tharsus, a Blyth-based robotics company, whose technology underpins the likes of DHL, Ocado and Rolls Royce. In just eight weeks, Tharsus created and manufactured Bump, a social distancing system designed to help address the safety concerns of employees in the workplace, and assist businesses in maximising workplace capacity.

The Royal Academy of Engineering has recognised the exceptional engineering achievements of individuals and teams in tackling Covid-19 / Picture: Tharsus

Bump is a personal motion system made up of wearable devices and corresponding base stations. The devices identify when employees move too close to one another, providing both wearers and businesses with real-time data on where and how regularly this occurs to inform workplace configuration. In the case of a localised outbreak, accrued data can be used to accurately understand the employees most at risk should a team member develop symptoms of Covid-19, ensuring that only vulnerable individuals are asked to quarantine, rather than the entire business or team.

Implemented by several FTSE 100 companies and validated by the Manufacturing Technology Centre as a key technology to enable social distancing in the workplace, the system has undergone an extensive trial process in factories, construction sites, distribution centres, laboratories and warehouses, with thousands of devices produced.

Professor Sir Jim McDonald FREng FRSE, president of the Royal Academy of Engineering, said: “The Covid-19 pandemic is the biggest public health crisis of our time and has presented society with multiple challenges. Engineering expertise and innovation has been central to the global fight to save lives and protect livelihoods.

“I am also incredibly proud of engineers everywhere who have worked round the clock to maintain essential services, critical supply chains and infrastructure in unprecedented circumstances, using their training and skills to find innovative solutions to a host of problems and to help mitigate the impact of Covid-19 on our daily lives.”

Professor Raffaella Ocone OBE FREng FRSE, chair of the Academy’s awards committee, added: “Engineering skills—including innovation and interdisciplinary collaboration—have proved to be of vital importance during the current pandemic. We were delighted that the breadth of nominations for these awards reflected so much of the extraordinary work engineers have been doing.

“While I am delighted that we are able to recognise some of these outstanding achievements with these awards, I am mindful that the important work of the vast majority of engineers will remain largely outside the public’s consciousness. They are all deserving of our thanks and admiration for their continuing positive contribution to society.”

Tharsus created and manufactured Bump, a social distancing system designed to help address the safety concerns of employees in the workplace / Picture: Tharsus

The full list of individuals and teams of engineers honoured:

VentilatorChallengeUK Consortium: Dick Elsy CBE led the initiative to combine the knowledge and skills of 33 UK technology and engineering businesses across the aerospace, automotive and medical sectors, to produce more than 13,000 Smiths and Penlon ventilator devices for the NHS.

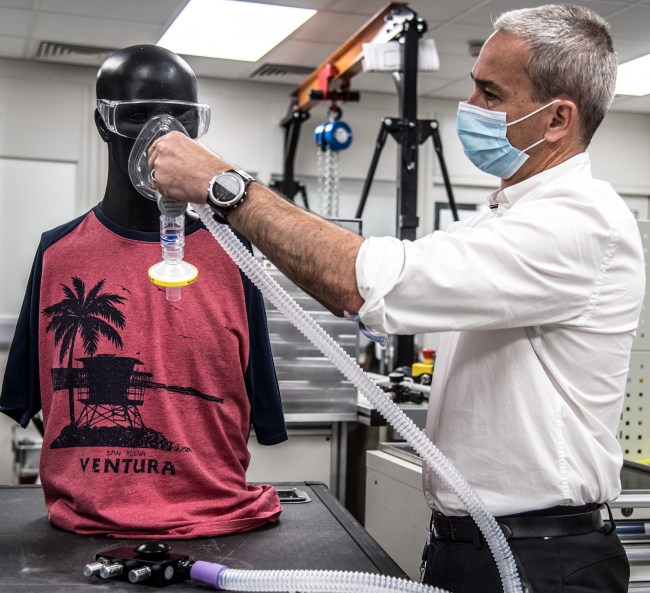

University College London-Ventura CPAP breathing aids were developed by a team led by Professor Rebecca Shipley and Professor Tim Baker working with Mercedes-AMG High Performance Powertrains. The team manufactured 10,000 breathing aids for use in UK hospitals and shared the designs with organisations from 105 other countries at no cost.

University of Cambridge Open Ventilator System Initiative team led by Dr Tashiv Ramsander developed a high-performance ventilator for manufacture in low and middle-income countries that became the first intensive care quality ventilator to be manufactured in Africa.

University of Southampton for PeRSo: The engineering team developed the Personal Respirator Southampton, a respirator for healthcare workers providing a much higher level of protection than surgical masks.

Babcock International Group for the rapid development and manufacture of a new medical ventilator product, Zephyr Plus, coordinated across several major companies in the UK and Germany, with 39 suppliers and MoD logistics.

Jean Morris and a team of young engineers from the National Physical Laboratory took a central role in building and testing prototype ventilators against a developing MHRA specification.

Dr Antony Robotham at the University of Plymouth who designed an environmentally friendly face shield, manufactured from recycled materials that are compostable or recyclable at the end of life.

Dr Dominic Pimenta, a cardiology registrar at one of London’s busiest hospitals who led the design and manufacture of face shields with the team at Makerversity for frontline NHS and care home staff. His charity, HEROES, has produced 100,000 reusable face shields as well as thousands of reusable gowns and scrubs.

Institute for Manufacturing, University of Cambridge: The IfM team helped local hospitals to make the best use of their resources, streamlining logistics for sourcing and storing vital PPE, informing decision-making on emergency demand, and developing a ventilator sharing system to be used in emergencies.

Tharsus for Bump, a social distancing system providing real-time alerts: Led by CEO Brian Palmer FREng and CTO Dave Swan, the technology’s smart data insights inform rapid decision making, allowing employers to maximise workplace capacity and providing data on team contact in the event of an outbreak.

A team from University College London worked with Mercedes-AMG High Performance Powertrains and manufactured 10,000 breathing aids for use in UK hospitals / Picture: thisisjude.uk

Dr Ravi Solanki and Raymond Siems, volunteers for the charity HEROES. In less than two days, their team turned an idea into a platform with genuine impact: a secure website through which more than 543,000 items of much-needed support have been provided to NHS workers, from sustainable PPE to counselling services and child care.

Professor Chris Toumazou FREng FRS FMedSci of Imperial College London for developing a rapid, affordable Covid-19 test based on a lab in a cartridge technology that provides test results in just over an hour. A total of 5.8 million tests are now being deployed throughout the NHS in preparation for the flu season.

Professor Zhanfeng Cui FREng and his team from the University of Oxford for the Oxford rapid viral RNA test for Covid-19. It can detect SARS-CoV-2 infection in 30 minutes and could be invaluable in developing countries because no specialist equipment is needed.

Professor Harris Makatsoris from King’s College London for developing a ‘factory-in-a-box’ that allows the rapid manufacture of synthetic RNA vaccines against the SARS-CoV-2 virus and minimises the space required for high-volume vaccine production.

Professor Catherine Noakes from the University of Leeds for her role in advising the NHS and the government at the highest level during the pandemic, shaping life-saving guidance based on her expertise in environmental and engineering controls.

Sewers4COVID from the University of Exeter, a team led by Professor Dragan Savic FREng applied machine learning to sewer epidemiology to estimate the number of infected people in a certain geographical area to track the spread of infection.

BOC Customer Engineering Services, who maintained the oxygen supplies to treat Covid-19 patients across the UK. BOC engineers set up oxygen systems at six Nightingale centres, including the largest medical oxygen system ever installed.

Matt Benson, Elliot Dervish and Jonathan Parker of Teledyne-e2v who developed and manufactured the Handy Hook for frontline NHS staff across Essex and London, to limit their interaction with surfaces carrying the virus.

Martyn Frackelton and Ian Watkins from Mott MacDonald who project managed NHS Nightingale London and NHS Nightingale North West, enabling the massive field hospitals to care for patients within two weeks of being announced.