2 minute read • published in partnership with MRPeasy

Case Study: Custom plastic components manufacturer achieves full traceability with MRP software

After a long search, Cellular Mouldings found a user-friendly MRP software platform that enabled it to improve administrative efficiency and achieve end-to-end traceability. “MRPeasy has been a major timesaver,” says Peter Matthews, MD.

From shoe soles to custom plastic components

Cellular Mouldings is a custom plastics manufacturer based in Corby, producing plastic extrusions, polyurethane foam products, and rigid polyurethane components for a variety of industries. It employs 34 people and has an annual turnover of around £3 million.

Spreadsheets became unmanageable

Until 2021, the company was using spreadsheets to manage their operation. While the business was growing, however, the spreadsheets were growing increasingly complex, finally starting to compromise effective communication and process efficiency.

The decision was made to implement software that would integrate the various functions of the company from incoming orders to outgoing shipments. All in all, they were looking to get a better overview of their whole operation that would enable them to understand and improve their efficiencies across the board. In addition, their growing customer base had started to ask for traceability measures to be in place.

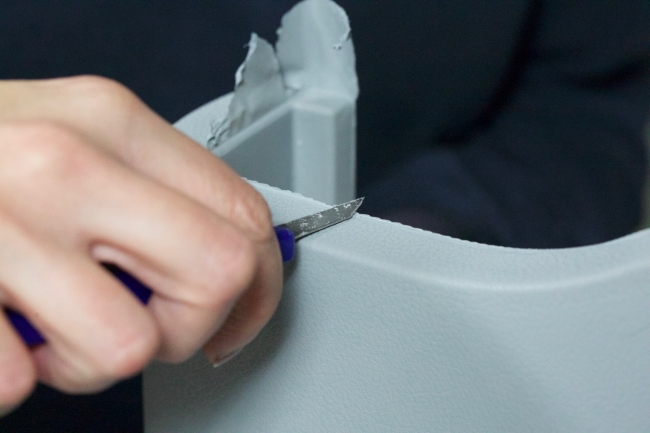

Picture: Cellular Mouldings

“A breath of fresh air”

Finding the right solution which would provide functionality to cover order management, shipment tracking, traceability, inventory tracking and purchasing proved a challenging task. Peter found most systems to be very clunky and complicated and therefore not suitable for the business. After a long search, however, Peter found a solution that changed his perspective completely.

“I came across MRPeasy, and it was a breath of fresh air,” he says. “The design was easy on the eyes, it was quick, intuitive to use, and accessible from anywhere. I clicked with it right away.”

After a rigorous testing process, the decision was made to adopt MRPeasy. The implementation process was spearheaded by Peter himself, with no external help, except for the software documentation and demo videos available on MRPeasy’s website, and MRPeasy’s support team.

“The fact that I could do it by myself shows just how intuitive the software is,” he states.

Picture: Cellular Mouldings

Having a complete overview of the operation

The system change coincided with an administrative employee retiring and a new person coming in, which presented a good opportunity to do things differently and increase the company’s administrative efficiency.

“Before using MRPeasy, we had no defined bills of materials,” Peter says. “All the information was scattered about.”

With the new system, Cellular Mouldings has finally established its BOMs and significantly improved its order management and tracking process. All events related to orders are now recorded from the moment an RFQ or order is received to when it is delivered, providing full product traceability.

“I now know what’s going on,” Peter states. “I don’t have to go around asking people, I can just open MRPeasy and look. This easy access to data has been a major timesaver for the company. We’re just scratching the surface with MRPeasy, but we’re already seeing significant improvements,” he says as a closing remark.