5 minute read • published in partnership with PP Control & Automation

Case Study: How PP C&A supported the expansion plans of Needham Group

Turning to the strategic manufacturing outsourcing expertise of PP Control & Automation could prove to be a pivotal decision for Needham Group as it aims to turn a £30m expansion blueprint into reality. There are exciting expansion plans brewing at Needham Group in Whitchurch, one of the UK’s leading family-run technology companies. The management team has unveiled a blueprint that will see it more than treble revenues to £30m between now and 2025, with the possibility of creating 30 new jobs in the process.

Founded by Roger Needham in 1962, the firm is looking to achieve this ambitious target by boosting export activity across its three divisions, increased investment in marketing, extending distribution networks and developing capacity to take on more bespoke projects. Whilst its traditional coding and ink technology businesses will play an important role, it is laser marking – the newest addition to the portfolio – that is offering the fastest route to growth and the biggest global potential.

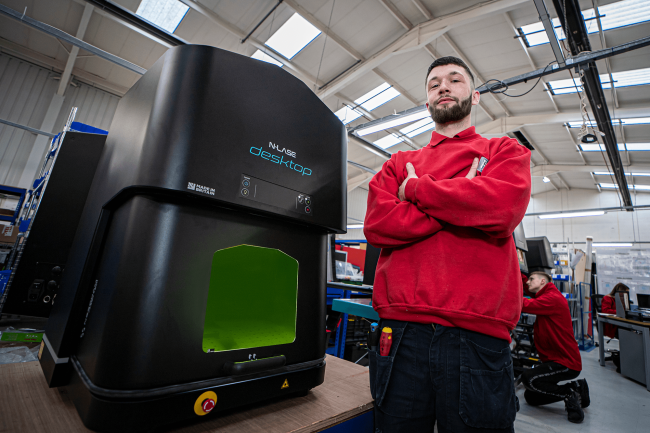

Picture: PP C&A

Needham Group first ventured into manufacturing laser marking machines in 2019 and has spent the last two years fine tuning its existing range of products, which spans N-Lase Desktop, Desktop Pro, Benchtop, Handheld, Workstation and Integrated Solutions. This is supplemented by a custom project offer, where the R&D and engineering teams will work with clients to develop new innovative uses for laser technology. It is widely accepted that this department is being hamstrung due to a lack of capacity, so the decision was taken to look for an outsourcing partner who could build its standard range.

The Group’s Head of Operations had worked with PP Control & Automation at a previous company and had seen for herself the multitude of benefits the right ‘choice’ could deliver. A meeting between the two businesses was quickly set up and several visits to PP C&A’s world class manufacturing facility in Cheslyn Hay soon followed, with a project team set up to build the desktop laser machine from a kit of supplied parts.

It didn’t take long for the strategic manufacturing outsourcing specialist to prove it could complete the build to the required standard. This gave engineers at Needham Group the confidence to advance discussions around introducing low volume production – a decision that will allow it to free-up capacity at its Whitchurch base and also give it more surplus manufacturing capability to support the anticipated rise in laser sales from £3m to £10m over the next three years.

Picture: PP C&A

Aled Ellis, managing director at Needham Group, said: “Our ‘USP’ is not in building the machines, but in developing the innovative uses and applications for laser technology – that’s where we come into our own and where we anticipate the real growth to come from. Once PP C&A proved they could build the prototype machine successfully, it made complete sense to look at a more strategic arrangement, first starting with the Desktop and Desktop Pro models and then, over time, moving on to the rest of our range. We have handed over the complete assembly process, including management of the supply chain.”

PP Control & Automation has a dedicated manufacturing cell in place that will increase as volumes build. This currently boasts four staff supporting the build, plus a wider support team covering the shared functions of Engineering, Supply Chain and Customer Services.

Tony Hague, CEO of PP C&A, added: “The initial volumes will be between 8 to 10 laser systems per month, rising to 20 if initial projections are realised. It’s all about making sure we fine tune the build and explore ways in which we can standardise processes to make assembly and customisation slightly easier than it is at the moment. The longer-term picture is that we will need to be in a position to build over 300 laser marking machines every year, something we can comfortably do at our site in the West Midlands.”

A few weeks into low volume production and the strategic partnership is already reaping dividends, with lead times halved to just two weeks from the bill of materials arriving in Cheslyn Hay. Quality guidelines have been surpassed and a number of efficiency improvements have been identified that could speed assembly up even further or give Needham Group designers the opportunity to modify standard models to encompass additional features.

Picture: PP C&A

David Needham, chairman of Needham Group, concluded: “PP C&A’s technical knowledge and electrical/mechanical build capabilities are second to none and it has got to grips with our laser technology quicker than we originally envisaged. We have seen the early signs of a partnership that could deliver us 300-strong volumes every year and this gives us a fantastic platform to aggressively market and sell our products in the UK and, importantly, increase our export activity through a number of key distributors.

“The other benefit of outsourcing the standard model build is that we have more than trebled capacity in our special projects team, giving our R&D experts and engineers the chance to take on more custom machines. We’ve always had demand in this field but could only agree to a limited number of builds. These restrictions have been lifted and we are very excited to make the most of what could be a £multi-million opportunity.”