2 minute read • published in partnership with Universal Wolf

Case Study: How Universal Wolf partnered with Lontra from prototype to full-scale manufacture

Lontra is a leading engineering, manufacturing and digital services business whose Blade Compressor® technology is its flagship innovation: the first widely applicable new compressor design in over 80 years. Its design and geometry mean that it leaks less, uses less energy and is more reliable than traditional machines of this type. Universal Wolf helped develop Lontra’s work to bring its revolutionary new Blade Compressor® technology to market.

With proven reliability gains and energy savings, the Lontra Blade Compressor® is the first clean-sheet compressor design in over 80 years. Lontra approached Universal Wolf with a basic design for the metalwork that would hold their core compressor technology and other high-value components. It needed a partner who could both support them in ensuring the design was suitable for manufacture through a new product introduction (NPI) process; and work with them to scale up the manufacture of the product.

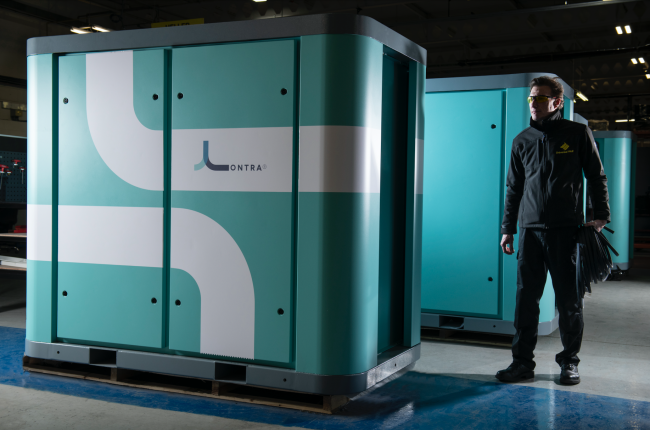

From prototype to full-scale manufacture, Universal Wolf helped Lontra brings its new technology to market / Picture: Universal Wolf

Complex metal fabrication: A better, smarter solution

Universal Wolf worked with Lontra on the design of the enclosure for its Blade Compressor® technology, from the prototyping stage of product development, through to working in partnership with them to manufacture the pre-production enclosures for the product.

Universal Wolf supported Lontra on the design and the future manufacturability of the enclosure, helping to create a unique product that is robust, efficient, and noise dampening – a critical consideration for those working alongside compressor technology in a manufacturing environment.

The partnership approach was key for Lontra, with both teams understanding that the relationship and collaboration between the companies would be key to the success of the project.

Cost effective, scalable manufacturing with ambitious design

The partnership between Universal Wolf and Lontra is built on trust. Universal Wolf supported Lontra as it took their compressor from prototype to full-scale manufacture, maintaining the design integrity of the enclosure and controlling costs at the same time.

The support means that the enclosure is designed for scaled-up manufacture and cost-effective, while also maintaining Lontra’s design ambitions – a unique, sleek and highly detailed casing that relays the quality within. With support from Universal Wolf, Lontra’s product is proven to be up to a third more efficient than its competitors, offering incredible energy savings and delivering significant improvements in reliability.

This was achieved by a collaborative working relationship in which Universal Wolf was able to match its partner’s ambition, working as part of an extended team to help bring the product to market and supporting their goal to make the world better. Universal Wolf says it looks forward to scaling with Lontra as it takes the innovative Blade Compressor® to the global market.