3 minute read • published in partnership with HVM Catapult

Feature: AMRC helps door manufacturer improve productivity with additive manufacturing technology

A Lancashire door manufacturer has invested in a 3D printer and is seeing ‘massive productivity gains’ after engineers from AMRC North West, which is part of the High Value Manufacturing Catapult, showed the company how additive manufacturing technology could support the production of its specialist fire doors.

Pendle Doors is a family-run business established in Burnley in the 1950s and relocated to a 30,000 sq ft manufacturing facility in Blackburn in 2007. It makes a range of doors for use across the healthcare, residential, leisure and education sectors.

The project with the University of Sheffield Advanced Manufacturing Research Centre North West, focused on its specialist fire doors and explored how additive manufacturing (3D printing) could be used to create a bespoke jig to improve the accuracy and repeatability of its manufacturing process.

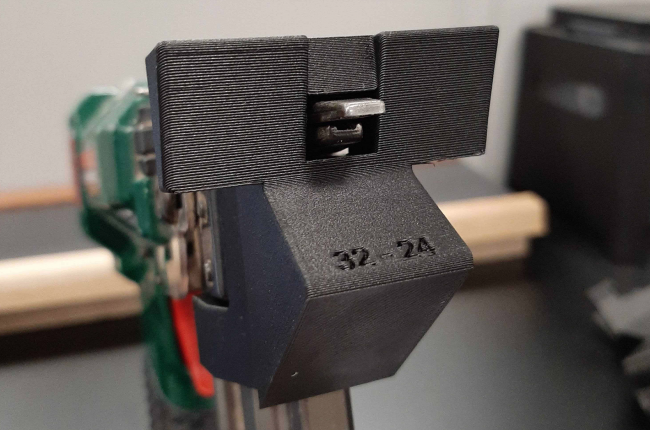

The AMRC has helped Pendle Doors to improve productivity by using additive manufacturing technology / Picture: AMRC/Pendle Doors

Dominic Haigh, project engineer at AMRC North West, said: “For obvious reasons, fire doors have to be manufactured to precise safety specifications and standards. The project with Pendle Doors was about ensuring the beading around the window panels in the fire doors were holding the glass inserts securely in position. Pendle Doors uses an air gun to insert the pins that hold the beading in place, and they wanted to explore the use of a jig to hold the air gun and ensure the pins were consistently going into the doors at the right angle.

“We started by making a CAD model of the air gun which was used as the base for developing the model for the jig. Then, using additive manufacturing, a prototype of the jig was produced. We tested and modified the first design to make sure it remained securely attached to the gun – and when we knew it worked well, we produced ten of the 3D printed jigs, so the company would have enough to last a while.

“The jig is ultimately about ensuring the repeatability and accuracy which brings a business peace of mind with products like this. It also saves costs as fewer products fail the rigorous safety checks they must go through. This was a project that really shows how businesses can use additive manufacturing in their processes and to save costs, even if they don’t use it to make their products directly.”

The company has now invested in its own additive manufacturing capability having seen an impressive rise in productivity, says Ryan Anderson, operations director at Pendle Doors.

He added: “As a result of working with the AMRC, we have purchased our own 3D printer that has been used for a multitude of things, from machine parts, to jigs, to a scaled plan of our factory. It has also helped our business to save a sum of money and we have also seen massive gains in productivity.

“The team at AMRC North West provided us with a brilliant idea to help us solve a production problem we were having. This enabled us to ensure we were staying compliant in our supply of potentially life-saving fire doors.”