5 minute read • published in partnership with igus

Feature: igus helps Greaves 3D take the lead in race to perfectly simulate motorsport

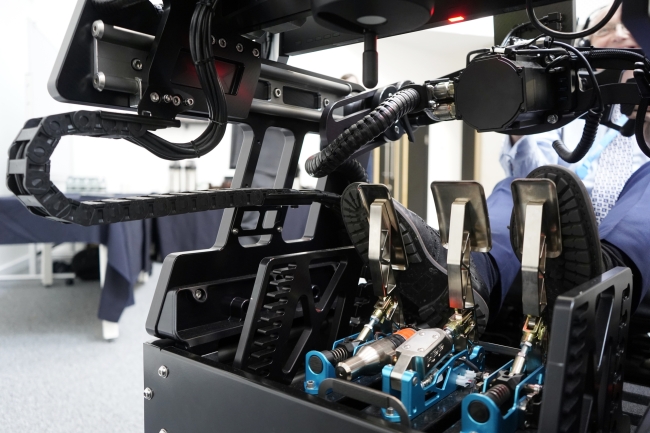

A super-realistic racing simulator has been developed by Greaves 3D Engineering that features 45 igus bearings, linear rails, drives and e-chains. The University of Northampton is using the simulator for deployment on its esports BSc degree course.

The driver grips the contoured steering wheel lightly and adjusts the seat position forward, angled back. The pedal box has an incredibly real feel; gunning the throttle awakens the senses. Touch controls have reassuring feedback. You’re ready on the track, surround screens close in, lights dim, the engine roars: a line of red lights; two lines; THREE lines, TWO, ONE, ZERO: GO GO GO!! Pinned back by the raw force – 80mph, 120mph, 160mph reached in seconds. Lightly brake, sharp left, the steering judders, throttle out the bend, long straight – foot to the floor! The race is on.

This is not Nürburgring or Silverstone but at the University of Northampton, where Greaves 3D Engineering’s race simulator delivers one of the most realistic simulated racing experiences available.

It pulls the driver into the race like they were actually there, using life-like feedback mechanisms in the wheel, pedals and seat to give the driver a “haptic-like” feel of the car and the track. The ultra-widescreen, triple monitor setup pulls forward to wrap the track around the driver’s field of vision. A functional, stripped down design, the simulator has been designed and built to give pure driving realism, more than appearance and branding. Greaves’ simulator really works, as serious drivers will attest.

Picture: igus

Driving simulators typically provide interactive movement in three axes to simulate the car’s movement. Rob Dumayne, director of bearing technology at igus UK, said: “This doesn’t do that – it has three fully linked and adjustable screens that provide the sense of movement. But the real heart of the simulator is the feedback technology.”

Feedback devices all over the rig can simulate the seat and steering wheel position of every class of racing, from entry-level karting to Formula One, so the driving position and handling is matched identically to that race class. Lean the seat position right back and down and you’re in an F1 car. Go upright and bring the pedal box into range, it’s a Touring or rally car. Every element of the simulator can be adjusted, and highly responsive feedback is at the heart of the machine. Components like the steering wheel and the servo-motor fitted to it, which provides the feedback, are the best in class.

igus motion plastics makes a winning team

To enable these multi-positional movements, Greaves turned to the motion plastics manufacturer, igus. igus bearings, drylin W linear rails and energy chains help provide the simulator with tiny, accurate and ultra-smooth movements.

“igus is involved with almost every mechanism in the racing simulator,” Rob says. “There are 45 separate igus products helping with the rig’s movement: the electronic seat in front and aft movements, the seat pivot, and all the screen swivel and vertical movements, use igus bearings and chains. A fully adjustable pedal box, where the pedals give the driver feedback as well, is equipped with igus self-lubricating bearings. Heights are adjusted using igus drylin W linear rails.” igus designed and built a special control box to control the seat movement that incorporates the igus D1 stepper motor control.

All igus bearings and chains are lubrication-free, dry running motion products, perfect for motorsport simulation. Racing is a high-end, sometimes luxury business and simulators are used at racetracks – drivers do not want oil and grease to spoil expensive race suits and boots.

Picture: igus

Growing eSport segment gives race simulator a new market

Peterborough-based Greaves 3D Engineering, one of the UK’s few race simulator manufacturers, partnered with igus and the University of Northampton to give students on its esports BSc (Hons) degree, and potentially other courses, use of the simulator. Students learn aspects of digital gaming development including user experience, marketing, broadcasting, media and esports coaching. The Greaves simulator is the perfect advanced hardware to enrich the course.

David Meenan, technical consultant at Greaves 3D Engineering, said: “The Greaves 3D simulator has been developed with a wealth of knowledge from our design team drawing experience from various disciplines in motorsport from karting to sportscars up to Formula 1,” “We have selected top tier components from the front runners in the sim market, including Precision Sim Engineering – LM Pro Steering wheel along with their bespoke dash. We coupled this with a Leo Bodnar steering system, a pairing that gives the ultimate racing car feel.

He adds, “We utilise the HPP simulation race car spec pedal box with a bespoke sim racing hydraulic brake system, that provides a realistic brake pedal feel which is critical to tuning the feel on the simulator to match that of real race cars. Precision Sim Engineering, Leo Bodnar and Packhorse flight cases have joined us alongside igus to make this exciting project with UON a roaring success.”

The simulator is available to both buy and lease. Traditional customers include race teams and motorsport consultants, and now esport companies, software designers and universities add to a widening market.

Picture: igus

Portable and modular

The simulator is modular and portable. It can be unpacked and re-packed safely with minimal training and is designed to fold away and stow in a customised flight case with integrated ramp for transportation. The unit unpacks and folds out simply, to be reassembled and connected in minutes. Race teams are using the Greaves simulator at live track events, as drivers can practice the course and fine-tune race settings digitally before heading out to the car for real. This can save teams costs in fuel and reduces risk of accident or damage in testing, and lets the drivers sharpen their skills while waiting for bad weather to clear.

igus has worked with Greaves 3D Engineering on the project for about two years and had provided all the bearings and e-chains in an exceptionally good value. igus can supply any product variation if the design needs modifying for a customer. Greaves 3D plans to continue promoting the rig to motorsport teams in the UK and abroad, while pushing on the fast-growing esports segment.

“The esports market has been growing for a number of years and Greaves 3D Engineering saw an opportunity for a more modular transportable solution to assist with the growing demands of this market,” says Jacob Greaves, Director, Greaves 3D Engineering. “With the help of our partners, we were able to achieve this. To then partner with the UON with their new esports degree course was a no-brainer.”