5 minute read • published in partnership with Stäubli

Feature: Providing the connectivity for efficient automotive manufacturing processes

There is no question that the automotive sector is one of the most competitive. Manufacturers continually strive to produce high volumes of vehicles, whilst responding to the challenges presented by different model variants, attaining, and maintaining high quality levels, optimising maintenance procedures, and of course ensuring the safety of operators. The transition to EVs e-mobility also presents additional challenges in terms of increasing flexibility within manufacturing lines, whilst maintaining the high levels of productivity required to remain competitive. Achieving these objectives is further complicated by the fact that automotive manufacturing involves multiple processes across the various different stages of build from parts production, assembly and finishing to powertrain.

At every stage in the manufacturing process, there is the need to connect a range of energies including: fluids, gases, electrical power, signals, and air. Regardless of whether you are an OEM manufacturer, an equipment supplier or a systems integrator, energy management is a key part of production. Handled safely and efficiently, this can assist in achieving and optimising the performance and flexibility levels demanded by the sector. The range of applications for energy management and connectivity are incredibly diverse, and the solutions are influenced by the specific requirements of each particular task.

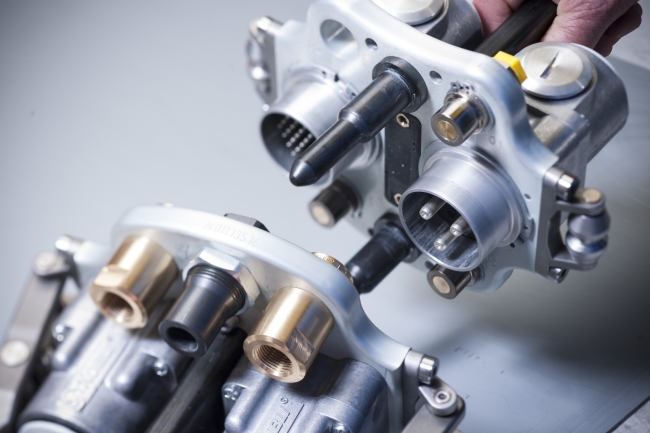

Picture: Stäubli

Within the press shop for example, reducing tool changeover time plays a key role in maintaining the highest levels of productivity. It is not uncommon for there to be several changeover procedures in a single shift, as the press shop produces the different panel components required for the model(s) being built at the time. These transfer press systems will have multiple tool and die sets which need to be exchanged, in many cases automatically, and of course the different services to these tool sets also need to be disconnected and then reconnected quickly and reliably. Stäubli’s advanced energy connections offer customised, innovative solutions for a comprehensive range of applications within the press shop.

Diverse applications in body in white

The body in white area within automotive manufacturing encompasses a wide range of different processes, as the various body panels are brought together to be assembled to form the main vehicle structure. The processes here include spot welding, arc welding – MIG or TIG depending upon the metal, and increasingly adhesive and sealant dispensing. Often, the majority of these task are performed by multiple robots, situated at the various workstations on the transfer line. Flexibility in this stage of production is paramount to allow the line to cater for different model variants, increased levels of personalisation on the vehicles, and also the different motive power options such as petrol or diesel internal combustion engines, hybrids, or fully electric powertrains.

With robots a key part of the production and assembly processes in this area, Stäubli’s automatic robot tool changers have become an essential part of many OEM production facilities. With robot tool changer product variants available for robot payloads up to 2,500kg, and for all of the mainstream robot manufacturers, Stäubli’s automatic robot tool changers are commonly used to exchange spot welding guns, component grippers, and end-of-arm-tooling systems.

Picture: Stäubli

The ability to dock, release and collect different tool configurations, whilst at the same time securely connecting multiple services, not only ensures the highest levels of flexibility, but also makes it possible to maintain the high productivity levels which are essential to automotive manufacturing. Stäubli’s centralised connection systems and quick release couplings are also widely used in other areas within body in white to facilitate quick and safe disconnection and reconnection of services.

Paint & final assembly

The automotive paint shop is one of the most critical areas in the manufacturing process, as the finish and standards produced here need to be of the highest quality and consistency to protect both the vehicle and the manufacturers brand. Stäubli technology makes it possible to achieve high-quality results through a comprehensive lineup of industrial paint connectors. Stäubli offers silicone-free quick connection solutions for air spray guns, quality and inspection, maintenance and cleaning, and filling and draining.

In applications where manual spray painting takes place, Stäubli offers quick connection solutions for this painting process. Easy-to-handle, the LAK quick couplings allow safe connection from the paint line to the spray gun. In addition, a drip-proof system on the end of the plug prevents the paint from dripping when disconnected, minimising paint loss. Versions are available for both water-soluble and solvent-based paints. Stäubli also provides quick couplings with anti-hose whip safety features for the compressed air supply to the spray gun.

The final assembly area in an automotive manufacturing plant encompasses multiple operations, many of which are performed using power tools, some electrically powered, and others pneumatically powered or using a combination of different services. Once again, reliable, and consistent connectivity is essential to meet the stringent production demands associated with an automotive assembly line. Stäubli’s connector technology plays a key role in achieving the highest productivity levels across many different applications including areas where compressed air is used and also at the fluid filling stations where each new vehicle receives its oil, fuel, and water.

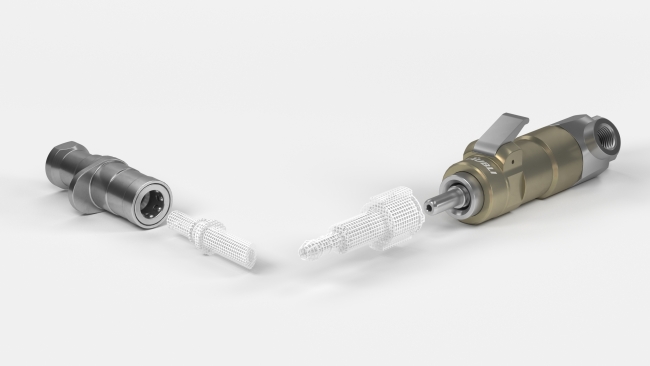

Picture: Stäubli

Powertrain assembly & testing

In addition to the assembly process, the main challenges in powertrain, both for EV and ICE, involve ensuring the proper functioning and interaction between different components (engine, motor, battery, inverter etc.) through operational testing. Stäubli develops solutions to meet individual customer specifications, such as the RPE range coupling designed in conformity with the different plug profile of components, type of fluids and the environment. Stäubli quick connectors are compact and offer both ease of handling and high performance, even for processes that present accessibility issues. Stäubli’s multi-connection solutions are ideal for automated testing processes, providing simultaneous connections in a single operation.

As for all industrial environments, safety is a priority, especially where there are electrical and high-pressure applications. Stäubli’s expertise, innovations and continuous involvement in safety standards make it possible to guarantee operator welfare. The user-friendliness of these superior-quality products is also an important factor in the design of these solutions, ensuring ease of operation and efficiency.