4 minute read

Ford Dagenham celebrates 90 year manufacturing milestone

Just over 90 years ago, at 1:16pm on October 1, 1931, the first Ford vehicle – a Ford AA truck – rolled off the production line at what was then Ford’s newest global production facility, Ford Dagenham.

Nine decades later – with nearly 11 million cars, trucks and tractors built during 71 years of vehicle production which, if placed end to end, would stretch more than 400,000km or 10 times around the world, and close to 50 million engines produced to date – Dagenham continues to play a major role in Ford’s European operations, building the advanced technology diesel engines that power many of Ford’s passenger and commercial vehicles.

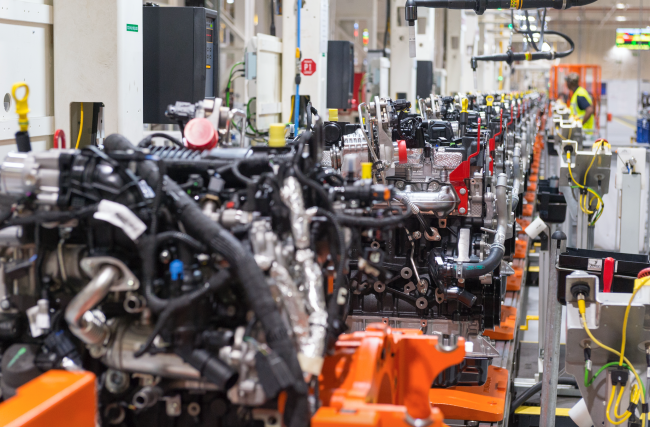

Ford Dagenham is celebrating 90 years of manufacturing – with close to 50 million engines produced at Dagenham to date / Picture: Ford of Britain

Kieran Cahill, chairman of Ford Motor Company and vice president for manufacturing at Ford of Europe, said: “Today is about celebrating with our employees the enormous contribution they and their predecessors have made over many generations to the success of Ford Dagenham. Still London’s largest manufacturing site, the fact that Ford Dagenham continues to be such an important part of our European manufacturing operations is testament to our employees’ involvement in the site’s past, present and future.”

In March of this year, Ford Dagenham was confirmed as the source of the latest advanced technology diesel engines for the next generation Ford Transit Custom range which will be built by Ford Otosan – Ford’s Turkish joint venture – in Kocaeli, Turkey, from early 2023. The next generation Volkswagen 1-tonne commercial vehicle will also be built in Kocaeli as part of the Ford Volkswagen Alliance.

Martin Everitt, plant manager at Ford Dagenham, added: “The anticipated incremental engine volumes this creates is expected to help safeguard jobs at Ford Dagenham. By 2025, we anticipate that up to 60 percent of our entire diesel engine volume will be destined just for the 1-tonne commercial vehicles being built by Ford Otosan.”

Ford also announced earlier this year that Ford Dagenham will supply the diesel engine for a new light commercial vehicle to be manufactured at Ford’s Craiova facility in Romania from 2023.

The plant currently builds diesel engines that power many of Ford’s passenger and commercial vehicles – nearly 11 million cars, trucks and tractors were built during 71 years of vehicle production at the site / Picture: Ford of Britain

Ford Dagenham – London’s largest manufacturing location

From 1931 to 2002, Ford Dagenham built some of Ford’s most iconic European vehicles, from the Model Y to the Anglia, and the Zephyr to the Fiesta. Engine manufacturing has also been integral to Ford Dagenham since its earliest days, and while diesel engine production will remain the mainstay of Ford manufacturing operations at Dagenham in the years ahead, Ford also is looking at other opportunities across the Dagenham site.

Announced in late June, the Ford Venari Alliance brings together Ford and emergency service vehicle provider Venari in plans to manufacture a new lightweight frontline ambulance. Based on the Ford Transit chassis cab and developed under “Project Siren”, the lightweight ambulance was designed with input from industry experts and frontline medical teams.

The Ford Venari ambulance is intended to be produced at a new facility in Ford Dagenham from 2022, utilising an existing, non-production location that will be refreshed to accommodate its manufacturing requirements. It is anticipated that the new business will create around 100 new jobs once production begins in 2022.

Ford and MS-RT, the Ford Pro commercial vehicles conversion partner and design-led automotive engineering company that creates specialised Ford vehicles, also announced that MS-RT is to establish a new £4m vehicle conversion facility at Ford Dagenham, due to increasing customer demand for the company’s vehicle conversions both in the UK and in a number of European markets.

The new Dagenham facility is intended to provide work for more than 50 new employees when it comes online in 2022, rising to over 120 new jobs when fully operational.

In 2020, Ford was part of the VentilatorChallengeUK consortium which manufactured respiratory ventilators for the NHS. Ford transformed an empty warehouse into an ISO 9001-accredited ventilator sub-assembly manufacturing facility in just three weeks – a feat that would usually take a full year. This involved both the Dagenham and wider Ford team, in conjunction with the local community, coming together to build, launch and staff the facility with up to 500 people a day at peak production.

In addition to its role in building the most complex ventilator sub-assemblies, Ford also played the pivotal role in helping to industrialise the production process of the ventilators to enable them to be built in large scale – just as Henry Ford’s moving assembly line led to mass production in the car industry in 1908 with the Model T.