4 minute read - 30th October 2023

Greater use of AI and machine learning to support future automation and productivity efforts

Manufacturers are set to see a surge in the use of artificial intelligence (AI) and machine learning as they push for greater automation and improvements in productivity, efficiency and quality, according to a new survey published by Make UK and Infor.

Published ahead of the AI Safety Summit at Bletchley Park this week, the survey shows that companies are increasing their investment in automation across a broad range of technologies and functions, from manufacturing processes to product design and development. These investments are set to accelerate in the next two years with greater automation leading to an increase in higher levels of skills and more than a quarter of companies (28%) saying they will have less need for lower skilled roles.

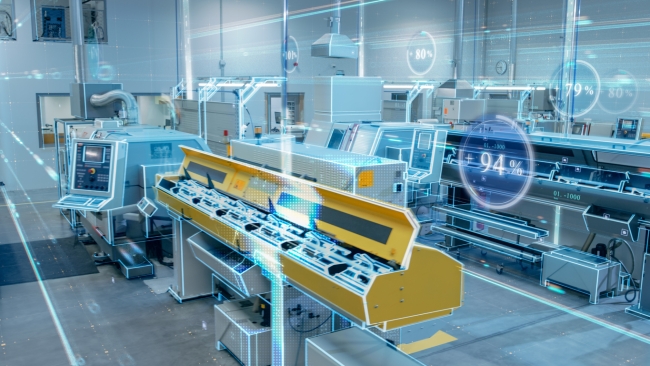

The use of artificial intelligence and machine learning is set to increase as manufacturers push for greater automation and improvements in productivity / Picture: Getty/iStock

However, despite this positive picture, Make UK says the majority of manufacturers believe the UK is failing to keep up with competitors, while significant barriers to further automation remain in the shape of a lack of technical skills, data integration and workplace culture. In response, Make UK is urging the government to roll out the Made Smarter scheme nationwide to help SMEs adopt digital technologies, as well as work with companies to address the continued shortfall of technical skills in the workforce and reform of the Apprentice Levy.

Verity Davidge, director of policy at Make UK, said: “The adoption of AI, automation and other game changing technologies by manufacturers is rapidly accelerating and will provide vital pieces in solving the productivity puzzle. But, there is still more to be done to match our competitors, especially among SMEs who face far greater hurdles in adopting digital technology. As well as tackling the digital skills barrier which remains the biggest hurdle, government should roll out the Made Smarter scheme across the UK. This has a proven success in delivering step change for SMEs on their automation journey.”

According to the survey, more than half of companies (55%) have already implemented or, are planning to implement, AI and machine learning to automate decision making processes and improve operational efficiency. In addition, four fifths of companies have already introduced or, are planning to introduce, augmented reality and virtual reality techniques in areas such as design and prototyping.

This is part of a wider push by companies to invest in automation with more than three quarters of companies (76%) having already done so, while almost six in ten companies (59%) plan to increase their expenditure compared to the previous twelve months. Furthermore, one in five companies plan to automate between a quarter and half of their processes in the next two years, while a quarter plan to automate between 10% and a quarter of their processes.

More than half of companies that responded to the survey are investing in artificial intelligence, machine learning and augmented reality / Picture: Getty/iStock

These investments are largely in improving manufacturing processes (65% of companies) and product design and development (49%). Companies have seen significant benefits as a result of investment, with improved productivity (60%), improved labour efficiency (49%) and a similar number seeing improved quality. However, despite this positive picture and increased investment plans, significant barriers to the adoption of automation remain in the form of a lack of technical skills by almost half of companies (46%), and integration and data challenges (41%). More than a third of companies are also citing high costs and workplace culture (38% and 36% respectively) as barriers.

Andrew Kinder, SVP for industry strategy at Infor, added: “We are seeing a substantial shift in the adoption of digital automation as manufacturers seek to improve efficiency, instill agility and drive greater productivity. While generative AI is still in its relative infancy, intent to capitalise on it is incredibly encouraging with many companies saying they are ‘aware of and planning to use’ the technology.

“Actions, however, speak louder than words. While the government clearly has a role to play in supporting AI adoption, manufacturers have an opportunity to take control in bridging the gap between intent and value in creating first-mover advantage. The technologies are now widely available, affordable and come with a typically fast return on investment, which all help manufacturers compete in increasingly challenging conditions.”

More than three quarters of respondents have invested, or are planning to invest, in automation / Picture: Getty/iStock

In addition, the survey shows a clear mismatch between policy incentives designed to boost investment and the expected return on investment (ROI) for companies. More than eight in ten companies expect up to five years for a positive impact of investment. In contrast, more than half of companies (56.4%) believe government investment policy is not sensitive to the time to see an ROI.

To help address these barriers and boost further automation, Make UK has made the following recommendations:

1 – Roll out the Made Smarter scheme nationwide. This scheme helps with the adoption of new technology in manufacturing businesses. It should also extend the remit of Made Smarter to include industrial decarbonisation to aid energy efficiency and transition to net zero.

2 – Make full expensing capital allowances permanent to enable businesses to plan investment over long leads.

3 – Expand the R&D tax credit to include capital expenditure to spur further digitalised R&D.

4 – Government should work with business organisations and sector specific bodies to help SME engagement with the Catapult Centres. This is especially important given the geographic distribution of the centres and would help more SMEs take advantage of their world leading facilities.