5 minute read • published in partnership with Atlas Copco

Insight: 10 steps to greener production when using compressed air

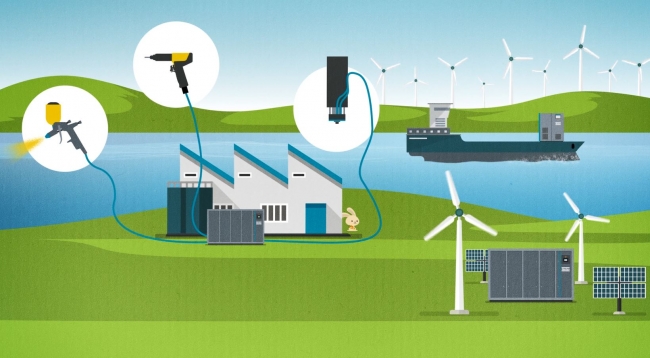

Energy reduction is the only way to a carbon-neutral economy – and it can start in the compressor room. Atlas Copco shares its 10 steps to greener production that can be taken right away and cost little. They are part of a continuous process to maintain peak production efficiency.

Compressed air production comes at a cost, with effects on a company’s bottom line as well as the environment. Energy costs make up around 75% of a compressor’s total cost of ownership. So, the wise course of action for responsible compressor owners and users is to take immediate and sustainable steps to help lower their energy consumption, reduce their carbon footprint, and make direct savings that will cost little to implement.

Step 1: Matching equipment to applications

Companies waste up to 50% of the power needed to generate compressed air through inappropriate use or inefficient systems design. In many cases, they may be able to invest in smaller, cheaper equipment, as long as they have eliminated inefficiencies, as follows.

1 – Isolate equipment when it is not in use. Use a simple manual isolation valve or an electronic valve to reduce equipment leakage.

2 – Keep cool. Compressed air equipment should be installed in the coolest location in the facility, and heat generated should be removed from the compressor room. Every 5°C rise in air temperature results in a 2% loss in efficiency.

3 – Keep clean. Dust in the air will block filters. Every 3 millibar pressure drop in the intake filter increases power consumption by 1%.

4 – Keep working pressure as low as possible. A higher working pressure means a higher power requirement, higher energy costs and a larger carbon footprint.

Action can be taken to help manufacturers lower their energy consumption, reduce their carbon footprint, and make direct savings that will cost little to implement / Picture: Atlas Copco

Step 2: Storage and distribution

Air receivers reduce the cycling time of air compressors, which increases their reliability and longevity. A larger air receiver can reduce power consumption. Consider separate compressed air systems if the majority of the production requires a lower pressure than the highest pressure requirement.

Companies often simply extend their pipework to meet the needs of new equipment, but this can cause pressure drops. There are three inexpensive ways to address this:

1 – Increase the main distribution pipework diameter. This will enlarge the stored volume and also reduce air velocity and pressure drop.

2 – Convert a dead-end or single pipework system into a ring-main pipework system. This increases volume and lowers the pressure drop. Lowering pressure differential by 0.5 bar can reduce the energy consumption of a compressor by up to 4%.

3 – Plug the leaks. The average production facility loses up to 20% of the compressed air it generates to leaks.

Step 3: Know air purity requirements

Treating compressed air costs energy and money, so it is important to know the level of air purity required.

Atmospheric air contains water vapour and dust. When that air is compressed, the concentration of these contaminants also increases, and they must be filtered out to protect equipment and maintain the required level of air purity.

Step 4: Understanding air demand

It is important to be aware of peak production periods and times of lower air demand. With a good understanding of actual demand, it may be possible to save money when investing in a new compressor. It is even possible that a new one is not needed.

Step 5: Compressor types and their benefits

There are many types of air compressors, with different advantages based on operating pressure and flow requirements.

Piston compressor: Highly efficient on-load and off-load, but may not be suitable for all duty cycles.

Scroll compressor: Mainly used in applications requiring small and clean oil-free airflows. Best used in intermittent air demand applications. Simple and easy to maintain.

Tooth compressor: Oil-free, rotary tooth compressors are suitable for small to medium-sized applications. Good for intermittent and continuous duty applications.

Rotary screw compressor: The most common type, used in many applications. Screw compressors can maintain peak efficiency over a wide variety of flows.

Centrifugal compressor: Centrifugal compressors are most efficient when running continuously and are best for large volumes of compressed air.

Making improvements should not be seen as a one-off exercise − it should be a continuous process to help maintain peak production efficiency / Picture: Atlas Copco

Step 6: Equipment control

More pressure means more energy consumption. Control methods differ, and the flow pattern will determine which is best for a given installation. Generally, compressors are set to run within a pressure band; the wider the pressure band, the more energy is consumed. One method to narrow the pressure band is to use variable-speed drive technology that can quickly react to changes in compressed air demand.

Step 7: Optimising system control

Central controllers manage the whole compressor room, matching the air supply to demand while offering pressure stability, and contributing significantly to energy efficiency. A smart central controller that accommodates different compressor technologies and control types will lower the overall pressure bands to deliver the required air output in the most efficient way.

Step 8: Energy recovery

Up to 90% of the electrical energy a compressor uses is converted into heat. That is why energy recovery is the best option to reduce energy consumption. Hot air can be captured and routed to a place where it is useful – for example, to warm a factory during the winter. Or heat can be removed from the cooling system via plate heat exchangers to heat water for boilers or showers.

Step 9: System maintenance

Maintenance is an essential component of an energy optimisation system. A well-maintained compressed air system will more than pay for its maintenance costs through energy savings.

Step 10: Remote monitoring

Smart remote monitoring technologies make it possible to connect industrial equipment over a secure network to mobile devices, to stay informed, optimise equipment performance from any location and receive messages that highlight potential issues. Operators can keep track of key performance parameters, including pressure, flow, motor and dryer speeds, and make adjustments when necessary – improving efficiency and saving energy.

10 steps in the right direction

Through adopting the 10 steps strategy, not only do compressor owners derive environmental, financial and productivity benefits, but they can make progress towards achieving ISO50001 standard certification. Certification demonstrates an organisation’s commitment to reducing energy use and greenhouse gas emissions.

Over 70% of companies are continuing to prioritise sustainability and environmental management issues.* Adopting good practice and adapting or replacing compressed air systems with energy efficient solutions is their guarantee of a reliable and sustainable air supply that reduces costs and promotes a greener, cleaner environment.