4 minute read • published in partnership with SteelScout

Insight: How digitisation can offer a boost to post-lockdown supply chain efficiency

In many industries, businesses have introduced new technology in order to improve workflows and processes. But there are some sectors that have been slower to adapt and there remains plenty of opportunities to improve efficiency, value and costs. Matt Yeates from SteelScout explores why, for many in manufacturing and engineering, sourcing materials is one such vital area that remains relatively traditional and untouched by digitalisation and opportunity abounds for both buyers and suppliers.

The use of digital platforms by manufacturers has accelerated rapidly as a result of COVID-19. As a recent study by McKinsey stated, B2B digital adoption has vaulted forward five years in just eight weeks during the pandemic.

But with so many manufacturing firms increasing the pace of their digital transformation, those involved in materials procurement are in danger of being left behind. This, combined with delays in the supply chain itself, presents the need for a new mindset.

The use of digital platforms by manufacturers for sourcing materials is one vital area that provides an opportunity to improve efficiency, value and costs / Picture: Getty/iStock

Manufacturing resilience

To better understand the impact of the pandemic on supply chains and the subsequent recovery, SteelScout, a metal procurement platform that digitally connects buyers with a UK network of suppliers, took the opinions of 100 manufacturing professionals across a number of thought-provoking issues.

The results were fascinating and took a magnifying glass to the issues that businesses have been challenged by, and in most cases have overcome.

The good news is that the majority of manufacturers surveyed are optimistic for recovery and expect demand to return to pre-pandemic levels before the end of year. More than 60% reported that they already have orders waiting to be fulfilled. Within our survey base alone, those orders exceeded £17m in value.

Most respondents had also found ways to continue working despite lockdown conditions, with remote working and rotation options proving popular. In fact, only 13% said that their company had been closed.

A more diverse supply chain needed

While optimism was high in general, there were some specific issues that gave cause for concern.

For example, many highlighted a lack of support and visibility in the supply chain. The majority of respondents (51%) are still contacting the same number of suppliers as they had been pre-pandemic, but 66% report that it has been harder to get hold of the materials they need in the timeframe required.

More than a third of respondents said that it was taking longer just to identity the ‘winning quote’ from suppliers, potentially causing further delays and adding inefficiency to the process.

When asked what the most valuable improvement would be to help fulfil post-pandemic orders, greater visibility of the supply chain was selected as first choice by 42% of those surveyed. A more diverse supplier network was selected by a fifth (21%) of respondents, whilst technology that increases efficiency was also a popular third choice (19%).

These supply chain issues do not come as surprise. A lack of visibility of suppliers and product range, together with pricing opacity in metal buying has long been a challenge for businesses. However the pandemic has exacerbated the situation with some suppliers forced to stop operations entirely.

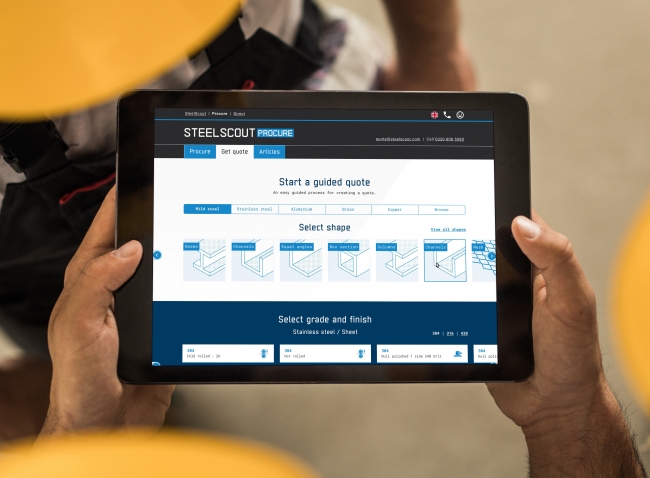

By adopting a digital mindset, metal procurement can become key to helping support UK manufacturing as it adapts to a new way of working / Picture: SteelScout

The solution could be a simple one using modern technology. In fact, the survey found that transformative digital platforms are already helping to make the procurement of materials an easy and efficient process. Nearly a third of those surveyed have increased their use of digital platforms in order to safeguard their supply chains.

SteelScout’s metal procurement platforms leverage bespoke digital technology to connect buyers with a UK network of suppliers, giving them access to highly competitive pricing 24/7 and de-risking supply by matching buyer requirements to supplier capabilities in real-time.

With the UK’s largest metal supplier network, our online platforms mean more choice and better value, saving customers time and boosting productivity.

A brighter future

The concerns expressed by many of those surveyed were often around issues that they felt were outside of their control. A repeat theme was the lack of visibility and options in the supply chain and procurement process, which in turn caused pain points around efficiency and deliverability.

However, with the digital services offered by SteelScout, these issues are now well within their control. By leveraging a UK-wide network of suppliers, manufacturers now have more visibility and a more diverse supplier network meaning more choice and flexibility of supply.

By applying the lessons from this crisis, and by adopting a digital mindset, metal procurement can become key to helping support UK manufacturing as it adapts to a new way of working. This will ensure the industry recovers strongly and is well-placed to face all the challenges and opportunities ahead.