3 minute read • published in partnership with Universal Wolf

Insight: What does a good new product introduction process look like – and why is it critical for a new product launch?

As inflation rises and costs of fuel and materials continue to increase, getting a new product launch right is more important than ever. Universal Wolf, experts in complex sheet metal fabrication, examine the importance of a robust and collaborative New Product Introduction process to successfully bring a new product to market.

NPI for new-to-market products

New Product Introduction (NPI) in the context of new-to-market products is the process of taking it from design, concept, or prototype; and making it ready for scalable, repeatable manufacture. It’s a step that, historically, many might skip in favour of rushing a product to market – a move which can have costly and insurmountable consequences for a business.

For new-to-market products in particular, NPI gives you proof that your product is suitable for manufacture. Given statistics indicate that anything between 75%-95% of new products fail before they even make it to market, this is an important verification to make. On receipt of drawings, Universal Wolf’s experienced Engineering team collaborate with our customers to adapt these drawings, so they are designed for manufacturing. This ensures efficient, affordable manufacture and smoother assembly; and eradicates the risk of the product failing at the manufacturing stage when it is too late to resolve any design issues.

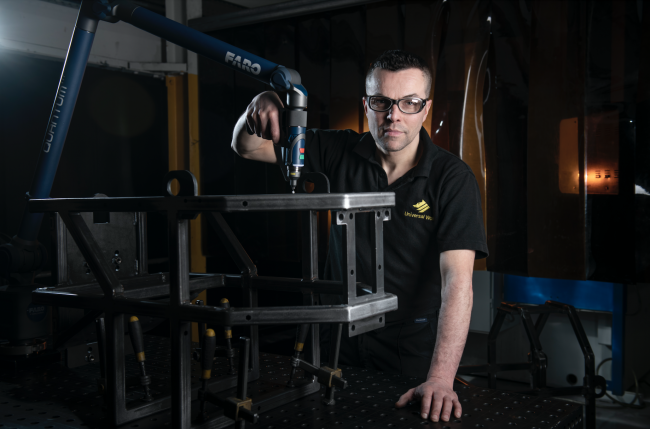

Getting a new product launch right is more important than ever and a robust and collaborative New Product Introduction process can ensure success / Picture: Universal Wolf

NPI at Universal Wolf

NPI is a cross-disciplinary process, involving colleagues from teams across the business including Project Management, Engineering, Fabrication, Quality, and Technical Experts.

The Universal Wolf NPI process consists of 4 main stage gates:

• Define

• Prepare

• Execute

• Validate

Stage 1: Define

During the ‘Define’ stage, our Project team reviews all data, information and drawings supplied. This early collaboration with the customer identifies development costs upfront, and allows us to solidify methods of manufacture, process mapping, capacity and resource requirements, jig/fixture design, risk assessments and NPI space setup. At this stage, we also work with the customer to understand their critical-to-quality (CTQ) requirements.

Stage 2: Prepare

During the ‘Prepare’ stage, we get everything ready for production. We determine the space and equipment needed to get the NPI cell ready for manufacture. It is at this point that the schedule is agreed with, and CAD/CAM drawings are signed off by, our customers.

Stage 3: Execute

The Execute phase involves the manufacture of a sample product. It is focused on moving the product from design into a defined form, while assessing any risk. Outputs include a validated product sample, drawing pack, bill of materials, specifications and operating procedures, weld qualifications and quality plan. At this point, we have a consistent, repeatable process for manufacturing.

Stage 4: Validate

Although the ‘Validate’ stage takes place after production launch, it is still a vital step in the NPI process. One of the key focus points during Validation is a review of ‘lessons learned’ – things that went well, things that need improvement, and how these can be integrated into future projects. This is a differentiator for Universal Wolf and ensures we are continuously improving our industry-leading NPI process.

New Product Introduction is an intensive process which adds real value to the product development and manufacturing process, reducing development time and cost through early collaboration, and improving product quality through the development of a consistent and clear process.