5 minute read

Opinion: An onshore battery ecosystem is vital to achieving the UK’s green industrial revolution

Kevin Brundish, CEO at AMTE Power, looks at the current state of electric vehicle production capabilities and what is needed to nurture a green onshore manufacturing ecosystem, in order to provide an independent supply chain support to UK manufacturing.

The lithium-ion battery is essential for electric vehicles (EV), it is also a core component for the renewable energy market transition. Yet the market, whilst trying to recover from the pandemic, is still reliant on a few large-scale overseas manufacturers creating uncertainty and risk.

Motorists’ increasing commitment to an electric future, combined with government incentives and optimised battery storage, is causing increased demand for manufacturing batteries. According to SMMT, 2020 saw the biggest annual increase in the number of EV registrations; up 66 per cent against 2019. Yet since the pandemic hit, global manufacturing supply chains have been interrupted, or even halted. This highlight’s how critical the onshore manufacturing capability is to both meet the demands of the nation, and to strengthen the resilience against future supply chain disruptions.

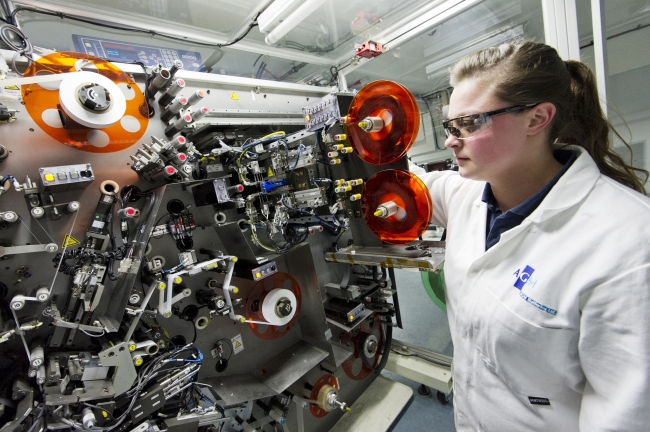

AMTE Power is a leading UK-based developer and manufacturer of lithium-ion battery cells for specialist and technically advanced markets, like motorsports / Picture: AMTE Power

The UK government plans to support businesses, like AMTE Power, to kickstart the economy again and make the UK a science and technology superpower. As part of the “build back better” initiative, the government is investing £500 million into the development and growth of EV batteries and the onshore supply chain. Reinforcing the UK’s manufacturing bases in this way will create more green jobs for the Green Industrial Revolution.

The recent 2021 G7 Summit saw world leaders agree on pledges of climate action, such as $2.8 billion to administer a switch to cleaner fuels. A move to renewable energy means that more people will opt for eco-friendly options, with battery-powered electric vehicles at the centre. To support such pledges and reach net zero targets, continued government support for the UK manufacturing supply chain is welcomed. Projects such as AMTE Power’s gigafactory expansion plans are pivotal to achieving Industrial Strategy targets.

The UK’s specialist heritage

The UK requires a robust infrastructure to bring its home-grown excellence in specialised, high performance products. Highly differentiated battery products with limited production will be key to attracting investment and helping the UK reinforce its market niche. A pipeline of innovative products, based on new chemistries and cell structures, will prove essential in solving long-standing problems with batteries in three crucial areas: power delivery, energy performance, and safety – and accelerating electrification.

Instead of relying on unpredictable and potentially unethical imports, the country’s rich talent pool can provide the skilled labour needed to set up the next vertical integration of manufacturing capability. Leveraging the UK’s world-class expertise in battery research and development enables the country to take control of the supply chain and exploit innovative, home-grown technology, whilst setting a much-needed standard for the energy storage industry.

The company is planning to build a 2-3GWh gigafactory in the UK, that will serve both the electric vehicle and battery storage markets / Picture: AMTE Power

Mission-critical infrastructure

In order to scale up EV production, the creation of gigafactories – capable of producing one GWh in energy output or more – across the UK is of the utmost importance. In fact, the Faraday Institute estimates that the expanding electric vehicle market necessitates the creation of seven 20GHW gigafactories to meet and realise this potential. Energy storage is also a driving force, with batteries set to contribute significantly to the grid regulation of a further 30GW of offshore wind by 2030, which is pivotal to achieving the UK target of 40GW of offshore wind by 2030.

EU gigafactories are essential to reduce reliance on the supply chain from China. China accounts for 70 per cent of lithium-ion cell production worldwide. Europe is at the start of its ‘gigafactory boom’, whilst currently producing only 8 per cent of the world’s lithium-ion cells.

Focus on net zero greenhouse gas emissions creates an opportunity for British manufacturers to support the Government’s plan to ‘build back better’ with onshore battery-cell production. Allowing to support growth in lower CO2 emission electric vehicles and increase in renewable energy storage

Gigafactories will support the UK’s unprecedented transition to electrification, and create a greener onshore manufacturing ecosystem, whilst helping to secure future economic prosperity by creating thousands of green jobs.

Earlier this year, AMTE Power became one of the first customers of the UK Battery Industrialisation Centre to test battery technologies in advance of scaled production / Picture: AMTE Power

A promising road ahead

As a business model that supports the global effort to reduce carbon emissions, the demand for batteries has only risen despite harsh economic conditions driven by the pandemic.

An unprecedented transition to electrification, via transport and renewable energy storage is taking place highlighting the critical nature of onshoring battery manufacturing capacity. This is creating favourable market dynamics and further opportunity for growth.

The UK Government is actively nurturing and building out its own infrastructure and manufacturing capability. Aimed to provide locally produced, sustainable batteries helping – lay the path for a growing market and decarbonising the future economy. By nurturing a green onshore manufacturing ecosystem, the UK can ensure quality and security of supply, promote economic prosperity, and work towards a sustainable future.