3 minute read • published in partnership with igus

RBTX from igus means nothing should stop you from catching the automation wave

Recent International Federation of Robotics (IFR) figures show the rising global demand for robots, partly in response to companies’ challenges with labour and inflation. Many do not know where to start – now igus’s RBTX platform is the perfect entry point for beginners and designers of small automation projects.

The International Federation of Robotics reports that there are now 3.5 million operational robots globally. And the total value of robot installations worldwide has reached an estimated $15.7 billion, according to the IFR’s February release “Top 5 Global Robotics Trends in 2023”.

The drive for increased productivity, the automation of manual tasks and insurance against a less reliable labour market is behind this rapid growth, and this is especially important in countries with high labour costs, such as the UK. Every factory manager and engineer knows that they need to automate parts of their operation, but it can be difficult to know where to start! As well as the basic robot units, an automation system requires other components including an end-effector such as a gripper, a control system, vision system, cable management, guarding – the list goes on. The added frustration is that components are not always compatible with each other, so building a robot to perform even a simple task becomes an engineering design project – and often companies are not confident in their skills for such work.

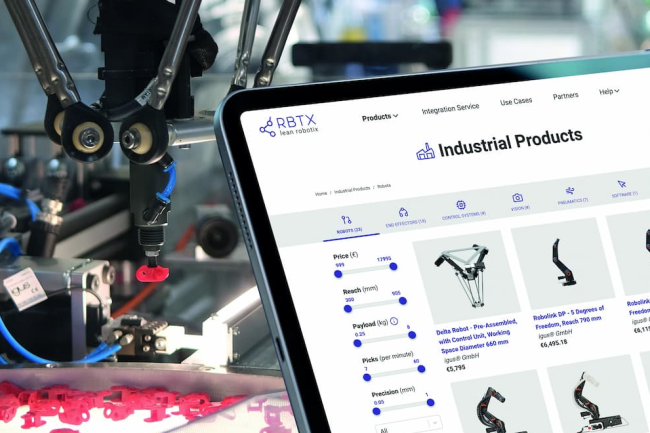

igus launched its RBTX platform to be the perfect entry point for beginners and designers of small automation projects / Picture: igus

Fear not, budding automation engineers: This problem is exactly what RBTX is designed to tackle.

Launched in 2020 in Germany and in late 2022 in the UK, RBTX.com is an online platform that allows engineers and buyers to configure a robot to precisely meet his or her needs, for the first time. The first step is to select the most appropriate robot for the task, using a simple selection tool that shows capabilities including payload, axes, reach and cost. The platform is semi-agnostic, in that several different manufacturers are represented here, including igus, Epson, Variobotic and Universal Robots.

Live technical support means you make the correct choice

Companies and users can also schedule a trial operation of their system physically or virtually, by testing the robots reach, its end effector operation and other features online – giving you confidence that the system can do what you want it to do.

igus robot engineers support the platform, and provide users with live advice and troubleshooting, to again ensure the equipment will fulfil their needs.

After choosing the most suitable robot for the job, the user is then guided through the rest of the selection process, choosing the suitable end-effector or gripper, vision system, safety systems and any material handling and conveyors required to move parts to and from the work zone. The RBTX tool has in-built intelligence that prevents certain parts which are incompatible from being selected. Any adapter plates or brackets which are required to fix the robot are added automatically so users do not forget these. The price of the package you’ve built is shown, and users can change equipment if it does not fit their budget. The complete system can be ordered, all parts will be delivered together, will fit together, and will work together.

RBTX allows anyone to implement automation and robotics in their factory, assembly area, pharmaceutical or science lab or processing facility. The design and selection process is simplified, and de-risks the complete process.