4 minute read • published in partnership with igus

Robotic lawn mower cuts an accurate path to success with help from igus

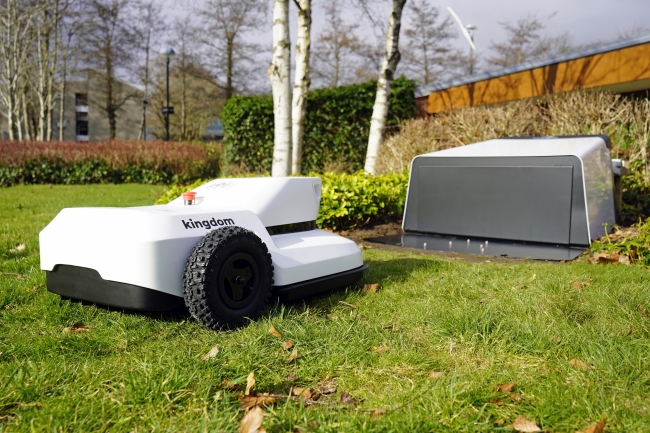

Labour shortages and carbon emissions of petrol mowers means robotic lawn mowers are on the rise. Kingdom Technologies turned to igus to help keep its pay-per-use robotic mower maintenance-free.

The greenskeeper surveys drone footage of the golf club. It’s a long fairway and the entire course needs cutting – this one alone could take all morning. But wait – while he’s mowing the fairway, the golf course’s robotic lawn mower can cut the acres of semi-rough, autonomously, quickly, and accurately.

He can programme it and forget, as the robot’s system operated by GPS will ensures only the precise area is cut, saving many hours across the whole course. The earliest robotic mowers date back to the 1960s, but have not become mainstream until recent years, possibly a combination of human pride in cutting the perfect lawn and the price point. In the last 10 years, the robotic mower market has taken off with several manufacturers launching new products, and mowing is now said to be the second largest category of domestic robots. US analysts say the market size was valued at $1.5 billion in 2021, and it is expected to reach over $4 billion by 20281.

Picture: igus

Founded in 2018 in Glasgow, Kingdom Technologies designs and manufactures robotic lawn mowers. The company has become one of the fastest growing robot companies in Scotland and the UK. In March 2022, Kingdom ran a seed investment round raising £2 million and it has recently deployed its first products in the US market.

Rather than target the domestic lawn mass market first, Kingdom Technologies has deliberately focussed on business clients occupying large areas, such as golf clubs, city councils and universities. Its robotic mower can cover 10 times larger areas than other robots in the market, as it cuts the grass moving in a human-like, efficient way, rather than random pattern currently used in the industry. In addition, Kingdom’s robot doesn’t require a boundary cable to map the areas and uses a patented web platform where the mowing areas are set online using satellite imagery.

Dry running affects supplier selection

Because the machine needs to operate autonomously, when designing the mower Kingdom Technologies needed technical products that are as close to maintenance free as possible. Weather is a big factor in running robotics outdoors, so they specifically wanted to avoid using lubricated ball bearings. Other criteria the team wanted for supplierswere good local engineering support, and product samples were available for trials – which led to a strong early relationship with igus. The igus Scotland sales engineer, Rob Day, provided the expertise that Kingdom Technologies were looking for.

igus bearings are used for several different movements in the mower. One is the cutting height adjustment, a critical application where tight tolerances are required. Rob worked with the engineers at Kingdom Technologies to select the right product. Tony Day, Kingdom’s head of mechanical engineering, is enthusiastic about the results. “The precision tolerances available in the igus bearings allowed us to design a cutting deck that has less than 1mm deviation in height across its width, giving a uniform, quality cut to our lawns. This is essential for our customer satisfaction.” he says.

Picture: igus

Another key area where igus parts are used is the lift sensor mechanism. This detects if the mower is lifted manually, putting the mower into a safe state mode whereby the motors are deactivated. Here, piston rings made of iglidur material are used to give a dry running, maintenance-free and reliable action in a very small package space.

The robotic mower is battery powered, and automatically navigates itself to the purpose-built charging station when required. The station is robust to protect the mower from damage, and has a secure door which opens to allow access. The door mechanism uses igus drylin linear bearings, and dryspin leadscrew nut running on a standard dryspin screw. This provides reliable, fail-safe operation in all weathers and environments.

Kingdom Technologies is using a pay-per-service business model; rather than selling the mowers, customers pay a monthly fee to use the robot. This novel approach makes the service more affordable for the customer, and the fees are typically less than having the lawn cut by a regular contractor. In addition, an increasing number of customers are turning to Kingdom for environmental reasons.

Joan Kangro, Kingdom CEO, says: “As well as operating quietly, the robot makes no emissions, and recent studies in the US show that around 5% of all air polluting particles are produced by ICE [petrol] lawn mowers!”

The robotic mower and charging station are developed at the West of Scotland Science Park, in Glasgow, assembled in Scotland and Kingdom selects local suppliers wherever possible. The potential market is huge, and with labour shortages and inflation, coupled with the 2022 seed capital injection and its first US exports recently, Kingdom Technologies’ robotic mower is on course to become a common sight on golf courses, sport pitches and hotel grounds everywhere.